Abstract

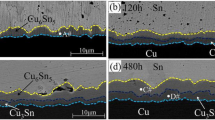

The morphological evolution and growth kinetics of interfacial Cu6Sn5 and Cu3Sn intermetallic compound (IMC) layers between Cu substrates and Sn-0.3Ag-0.7Cu-xMn (x = 0 wt.%, 0.02 wt.%, 0.05 wt.%, 0.1 wt.%, and 0.15 wt.%) (SAC0307-xMn) solders were investigated. After ageing, the uneven scallop-like morphology of Cu6Sn5 transforms into a layer-like morphology, and the Cu3Sn morphology remains layer-like. Kirkendall voids at the Cu/Cu3Sn interface and in the Cu3Sn layer are observed at high ageing temperatures. The Cu6Sn5 layer predominantly governs the growth of the total IMC layer at low ageing temperatures, whereas the Cu3Sn layer primarily influences the total IMC layer at high ageing temperatures. The growth of the Cu6Sn5 and Cu3Sn layers fits a power–law relationship with an exponent between 0.44 and 0.82, indicating that IMC growth is primarily controlled by diffusion but may also be affected by interfacial reactions. The activation energies and interdiffusion coefficients of the Cu6Sn5 and Cu3Sn layers were determined. The addition of Mn nanoparticles strongly affected the growth of the Cu6Sn5 layer but weakly impacted the growth of the Cu3Sn layer, particularly at low ageing temperatures. Adding Mn nanoparticles to the SAC0307 solder can evidently increase the activation energy of the Cu6Sn5 layer, reduce the atomic diffusion rate, and inhibit the excessive growth of the Cu6Sn5 IMC.

Similar content being viewed by others

References

Y. Liu, F. Sun, Y. Liu, and X. Li, J. Mater. Sci. Mater. Electron. 25, 2627 (2014).

A.A. El-Daly, A.E. Hammad, G.S. Al-Ganainy, and M. Ragab, Mater. Sci. Eng. A 608, 130 (2014).

D.X. Luo, S.B. Xue, and S. Liu, J. Mater. Sci. Mater. Electron. 25, 5195 (2014).

M. Yang, Y.H. Ko, J. Bang, T.S. Kim, C.W. Lee, and M. Li, Mater. Charact. 124, 250 (2017).

N. Mookam and K. Kanlayasiri, J. Mater. Sci. Technol. 28, 53 (2012).

K. Kanlayasiri, M. Mongkolwongrojn, and T. Ariga, J. Alloys Compd. 485, 225 (2009).

N. Mookam and K. Kanlayasiri, J. Alloys Compd. 509, 6276 (2011).

X. Yan, K. Xu, J. Wang, X. Wei, and W. Wang, Solder Surf. Mt. Tech. 28, 215 (2016).

F. Cheng, F. Gao, J. Zhang, W. Jin, and X. Xiao, J. Electron. Mater. 46, 3424 (2011).

L.C. Tsao, S.Y. Cheng, C.W. Chen, and T.Y. Chen, Mat. Sci. Eng. A 658, 159 (2016).

R.W. Wu, L.C. Tsao, and R.S. Chen, J. Mater. Sci. Mater. Electron. 26, 1858 (2015).

K. Kanlayasiri and K. Sukpimai, J. Alloys Compd. 668, 169 (2016).

H. Wang, S. Xue, and J. Wang, J. Mater. Sci. Mater. Electron. 28, 8246 (2017).

J. Wu, S. Xue, J. Wang, J. Wang, and S. Liu, J. Mater. Sci. Mater. Electron. 28, 10230 (2017).

Y. Gu, X. Zhao, Y. Li, Y. Liu, Y. Wang, and Z. Li, J. Alloys Compd. 627, 39 (2015).

Y.M. Leong and A.S.M.A. Haseeb, Materials 9, 522 (2016).

D.A. Shnawah, S.B.M. Said, M.F.M. Sabri, I.A. Badruddin, and F.X. Che, J. Electron. Mater. 41, 2631 (2012).

W. Liu, N.C. Lee, A. Porras, M. Ding, A. Gallagher, A. Huang, S. Chen, and J. C. Lee, Electronic Components and Technology Conference (2009), pp. 994–1007.

L.W. Lin, J.M. Song, Y.S. Lai, Y.T. Chiu, N.C. Lee, and J.Y. Uan, Microelectron. Reliab. 49, 235 (2009).

Y. Tang, S.M. Luo, K.Q. Wang, and G.Y. Li, J. Alloys Compd. 684, 299 (2016).

G.Y. Li, X.D. Bi, Q. Chen, and X.Q. Shi, J. Electron. Mater. 40, 165 (2011).

W.L. Chiu, C.M. Liu, Y.S. Haung, and C. Chen, Mater. Lett. 164, 5 (2016).

C.E. Ho, T.T. Kuo, C.C. Wang, and W.H. Wu, Electron. Mater. Lett. 8, 495 (2012).

L. Zhang and L.L. Gao, J. Alloys Compd. 635, 55 (2015).

I.E. Anderson, J.W. Walleser, J.L. Harringa, F. Laabs, and A. Kracher, J. Electron. Mater. 38, 2770 (2009).

C.C. Pan, C.H. Yu, and K.L. Lin, Appl. Phys. Lett. 93, 061912 (2008).

D.A. Porter and K.E. Easterling, Phase Transformations in Metals and Alloys (London: Chapman & Hall, 1981).

R.E. Reed-Hill, Physical Metallurgy Principles (Boston: PWS, 1972).

L.C. Tsao, J. Alloys Compd. 509, 2326 (2011).

L.C. Tsao, J. Alloys Compd. 509, 8441 (2011).

X. Deng, G. Piotrowski, J.J. Williams, and N. Chawla, J. Electron. Mater. 32, 1403 (2013).

Acknowledgements

The authors acknowledge the support of the Project of Guangdong Province Universities and Colleges Pearl River Scholar Funded Scheme, China (Grant No. 2016), the Project of Guangdong Province Support Plans for Top-notch Youth Talents, China (Grant No. 2016TQ03N704), the Pearl River S&T Nova Program of Guangzhou, China (Grant No. 201610010157), and the Outstanding Young Teacher Project of Guangdong Province Universities and Colleges, China (Grant No. YQ2015093).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tang, Y., Luo, S., Li, Z. et al. Morphological Evolution and Growth Kinetics of Interfacial Cu6Sn5 and Cu3Sn Layers in Low-Ag Sn-0.3Ag-0.7Cu-xMn/Cu Solder Joints During Isothermal Ageing. J. Electron. Mater. 47, 5913–5929 (2018). https://doi.org/10.1007/s11664-018-6481-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-018-6481-5