Abstract

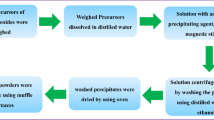

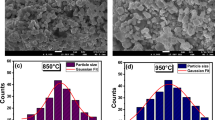

0.5Ba0.90Ca0.10TiO3-0.5BaTi0.88Zr0.12O3-0.1%CuO-xEu (BCT-BZT-Cu-xEu; x = 0–0.90%) lead-free ceramics were sintered at 1220°C with as-synthesized nanoparticles by a modified Pechini method. The structural characteristics and electrical properties of the ceramics that were influenced by varying europium-doping were investigated. All the ceramics featured high densification (relative density: ∼ 96%). X-ray powder diffraction results indicated the samples possessed pure orthorhombic phase. The maximum relative permittivity (ε r, 10869) was found at x around 0.30%. Europium ions could dope on different substitution sites in the ABO3 lattice, which evidently influenced electrical properties with various volumes of oxygen vacancy. Moreover, the formation mechanisms of oxygen vacancy and defect electron complexes were stated. The piezoelectric properties were impacted by defect electron complexes, internal stress, ionic electronegativity, etc. The optimal electrical properties, i.e., d 33 = 384 pC/N, Q m = 92, and k p = 0.36, were detected at x = 0.45%.

Similar content being viewed by others

References

B. Jaffe, R.S. Roth, and S. Marzullo, J. Appl. Phys. 25, 809 (1954).

T.R. Shrout and S. Zhang, J. Electroceram. 19, 113 (2007).

W. Liu and X. Ren, Phys. Rev. Lett. 103, 257602 (2009).

D.S. Keeble, F. Benabdallah, P.A. Thomas, M. Maglione, and J. Kreisel, Appl. Phys. Lett. 102, 092903 (2013).

M. Tanmoy, R. Guo, and A.S. Bhalla, J. Am. Ceram. Soc. 91, 1769 (2008).

Y. Pu, M. Yao, H. Liu, and T. Frömling, J. Eur. Ceram. Soc. 36, 2461 (2016).

Z. Sun, L. Li, H. Zheng, and L. Luo, Ceram. Int. 42, 12246 (2016).

H. Yang, F. Yan, G. Zhang, Y. Lin, and F. Wang, J. Alloys Compd. 720, 116 (2017).

X. Chen, X. Ruan, K. Zha, X. He, J. Zeng, Y. Li, L. Zheng, C.H. Park, and G. Li, J. Alloys Compd. 632, 103 (2015).

R. Hayati, M.A. Bahrevar, T. Ebadzadeh, V. Rojas, N. Novak, and J. Koruza, J. Eur. Ceram. Soc. 36, 3391 (2016).

J. Wu, W. Mao, Z. Wu, and Y. Jia, Mater. Lett. 166, 75 (2016).

I. Coondoo, N. Panwar, H. Amorín, V.E. Ramana, M. Algueró, and A. Kholkin, J. Am. Ceram. Soc. 98, 3127 (2015).

Z. Wang, W. Li, R. Chu, J. Hao, Z. Xu, and G. Li, J. Alloys Compd. 689, 30 (2016).

P. Du, L. Luo, W. Li, Q. Yue, and H. Chen, Appl. Phys. Lett. 104, 152902 (2014).

D.I. Bilc and D.J. Singh, Phys. Rev. Lett. 96, 147602 (2006).

D.K. Patel, B. Vishwanadh, V. Sudarsan, and S.K. Kulshreshtha, J. Am. Ceram. Soc. 96, 3857 (2013).

R.A. Eichel, E. Erünal, P. Jakes, S. Körbel, C. Elsässer, H. Kungl, J. Acker, and M.J. Hoffmann, Appl. Phys. Lett. 102, 242908 (2013).

H. Sun, S. Duan, X. Liu, D. Wang, and H. Sui, J. Alloys Compd. 670, 262 (2016).

Y.S. Tian, Y.S. Gong, D.W. Meng, and Y.J. Li, J. Mater. Sci. 50, 6134 (2015).

Y.S. Tian, Y.S. Gong, Z.L. Zhang, and D.W. Meng, J. Mater. Sci. Mater. Electron. 25, 5467 (2014).

J. Wu, D. Xiao, W. Wu, Q. Chen, J. Zhu, Z. Yang, and J. Wang, J. Eur. Ceram. Soc. 32, 891 (2012).

L. Dong, D.S. Stone, and R.S. Lakes, J. Appl. Phys. 111, 084107 (2012).

K.W.P. And, Y.E. Sung, S. Han, A.Y. Yun, and T. Hyeon, J. Phys. Chem. B 108, 939 (2004).

M. Park and J.Y. Yoo, J. Electron. Mater. 41, 3095 (2012).

M. Jiang, Q. Lin, D. Lin, Q. Zheng, X. Fan, X. Wu, H. Sun, Y. Wan, and L. Wu, J. Mater. Sci. 48, 1035 (2013).

S. Ye, J. Fuh, L. Lu, Y.I. Chang, and J.R. Yang, RSC Adv. 3, 20693 (2013).

D. Fu, M. Itoh, S.Y. Koshihara, T. Kosugi, and S. Tsuneyuki, Phys. Rev. Lett. 100, 227601 (2008).

H.S. Kim, H.M. Christen, M.D. Biegalski, and D.J. Singh, J. Appl. Phys. 108, 054105 (2010).

W. Liu, J. Wang, X. Ke, and S. Li, J. Alloys Compd. 712, 1 (2017).

B. Qu, H. Du, and Z. Yang, J. Mater. Chem. C 4, 1795 (2016).

Y.S. Tian, S.Y. Li, Y.S. Gong, D.W. Meng, J.P. Wang, and Q.S. Jing, J. Alloys Compd. 692, 797 (2017).

R.K. Mishra, D.K. Pradhan, R.N.P. Choudhary, and A. Banerjee, J. Magn. Magn. Mater. 320, 2602 (2008).

R. Rani, S. Singh, J.K. Juneja, K.K. Raina, and C. Prakash, Ceram. Int. 37, 3755 (2011).

W. Wang, L.D. Wang, W.L. Li, D. Xu, Y.F. Hou, and W.D. Fei, J. Alloys Compd. 624, 284 (2015).

X. Tang, K.H. Chew, and H. Chan, Acta Mater. 52, 5177 (2004).

A.A. Bokov and Z.G. Ye, J. Mater. Sci. 41, 31 (2006).

J. Hao, W. Bai, and W. Li, J. Am. Ceram. Soc. 95, 1998 (2012).

X. Chao, Z. Wang, Y. Tian, Y. Zhou, and Z. Yang, Mater. Res. Bull. 66, 16 (2015).

P. Zhou, B. Zhang, L. Zhao, and L. Zhu, Ceram. Int. 41, 4035 (2015).

J. Wu, Z. Wu, W.J. Mao, and Y.M. Jia, Mater. Lett. 149, 74 (2015).

T. Badapanda, S. Sarangi, B. Behera, S. Parida, S. Saha, T.P. Sinha, R. Ranjan, and P.K. Sahoo, J. Alloys. Compd. 645, 586 (2015).

M.C. Ehmke, J. Daniels, J. Glaum, M. Hoffman, J.E. Blendell, and K.J. Bowman, J. Am. Ceram. Soc. 96, 2913 (2013).

E.E. Shafee and S.M. Behery, Mater. Chem. Phys. 132, 740 (2012).

E.K. Akdoğan, K. Kerman, M. Abazari, and A. Safari, Appl. Phys. Lett. 92, 112908 (2008).

Y. Saito, H. Takao, T. Tani, T. Nonoyama, K. Takatori, T. Homma, T. Nagaya, and M. Nakamura, Nature 432, 84 (2004).

S.W. Zhang, H.L. Zhang, B.P. Zhang, and G.L. Zhao, J. Eur. Ceram. Soc. 29, 3235 (2009).

A. Srinivas, R.V. Krishnaiah, V.L.N. Iranjani, S.V. Kamat, T. Karthik, and S. Asthana, Ceram. Int. 41, 1980 (2015).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tian, Y., Li, S., Sun, S. et al. Influence of Europium Doping on Various Electrical Properties of Low-Temperature Sintered 0.5Ba0.90Ca0.10TiO3-0.5BaTi0.88Zr0.12O3-0.1%CuO-xEu Lead-Free Ceramics. J. Electron. Mater. 47, 684–691 (2018). https://doi.org/10.1007/s11664-017-5839-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-017-5839-4