Abstract

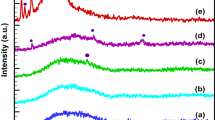

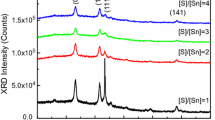

In this study, nanostructured tin sulfide (SnS) thin films were synthesized on glass substrates by means of low-cost chemical bath deposition using non-toxic trisodium citrate (TSC) as complexing agent. The influence of varying molar concentration of TSC (0.15–0.21 M) on the tin sulfide phases was investigated. The structural, morphological and optical properties of the films were studied using x-ray diffraction (XRD), field emission scanning electron microscopy (FESEM), Raman spectroscopy and optical absorption spectroscopy. The XRD patterns confirmed an orthorhombic polycrystalline structure of the as-prepared SnS thin films. The values of average crystalline size and texture coefficient of the major XRD peak increased with increasing TSC concentration. The FESEM micrographs revealed that the synthesized thin films are characterized by a flake-stack structure. The Raman spectra of the films showed the presence of a Sn2S3 peak, which gradually declined in intensity until almost disappearing as the TSC concentration increased from 0.15 M to 0.21 M. The direct energy band gaps estimated from ultraviolet–visible–near-infrared absorption spectra also varied between 1.64 eV to 1.1 eV with increasing TSC concentration from 0.15 M to 0.21 M. The results indicate the crucial role of TSC in the synthesis of SnS nanostructured thin films.

Similar content being viewed by others

References

J. Mou, W. Zhang, J. Fan, H. Deng, and W. Chen, J. Alloys Compd. 509, 961 (2011).

D.P. Singh, Sci. Adv. Mater. 2, 245 (2010).

J.J. Hassan, Z. Hassan, and H. Abu-Hassan, J. Alloys Compd. 509, 6711 (2011).

E. Guneria, C. Ulutas, F. Kirmizigul, G. Altindemir, F. Gode, and C. Gumus, Appl. Sur. Sci. 257, 1189 (2010).

B.P. Bade, S.S. Garje, Y.S. Niwate, M. Afzaal, and P. O’Brien, Chem. Vap. Depos. 14, 292 (2008).

B. Ghosh, R. Roy, S. Chowdhury, P. Banerjee, and S. Das, Appl. Sur. Sci. 256, 4328 (2010).

J. Vidal, S. Lany, M. d’Avezac, A. Zunger, A. Zakutayev, J. Francis, and J. Tate, Appl. Phys. Lett. 100, 032104 (2012).

K.T. Ramakrishna Reddya, N. Koteswara Reddy, and R.W. Miles, Sol. Energy Mater. Sol. C. 90, 3041 (2006).

T. Miyawaki and M. Ichimura, Mater. Lett. 61, 4683 (2007).

B. Ghosh, M. Das, P. Banerjee, and S. Das, Semicond. Sci. Tech. 24, 025024 (2009).

Y. Wang, H. Gong, B. Fan, and H. Guangxia, J. Phys. Chem. C 114, 3256 (2010).

Z. Zaimal, M.Z. Hussin, A. Kassim, and A. Ghazali, J. Mater. Sci. Lett. 16, 1446 (1997).

R.W. Miles, O.E. Ogah, G. Zoppi, and I. Forbes, Thin Solid Films 517, 4702 (2009).

B. Ghosh, M. Das, P. Banerjee, and S. Das, Appl. Sur. Sci. 254, 6436 (2008).

K. Hartman, J.L. Johnson, M.I. Bertoni, D. Recht, M.J. Aziz, M.A. Scarpulla, and T. Buonassisi, Thin Solid Films 519, 7421 (2011).

A. Tanusevski and D. Poelman, Sol. Energy Mater. Sol. C. 80, 297 (2003).

N.K. Reddy and K.T.R. Reddy, Thin Solid Films 325, 4 (1998).

M.T.S. Nair and P.K. Nair, Semicond. Sci. Tech. 6, 132 (1991).

P. Pramanik, P.K. Basu, and S. Biswas, Thin Solid Films 150, 269 (1987).

D. Avellaneda, G. Delgado, M.T.S. Nair, and P.K. Nair, Thin Solid Films 515, 5771 (2007).

F. Gode, E. Guneri, and O. Baglayan, Appl. Sur. Sci. 318, 227 (2014).

E. Guneri, F. Gode, C. Ulutas, F. Kirmizigul, G. Altindemir, and C. Gumus, Chalcogenide Lett 7, 685 (2010).

L.A. Burton, D. Colombara, R.D. Abellon, F.C. Grozema, L.M. Peter, T.J. Savenije, G. Dennler, and A. Walsh, Chem. Mater. 25, 4908 (2013).

V. Robles, J.F. Trigo, C. Guillén, and J. Herrero, J. Mater. Sci. 48, 3943 (2013).

R.E. Banai, J.C. Cordell, G. Lindwall, N.J. Tanen, S.-L. Shang, J.R. Nasr, Z.K. Liu, J.R.S. Brownson, and M.W. Horn, J. Elctron. Mater. 45, 499 (2016).

M. Calixto-Rodriguez, H. Martinez, A. Sanchez-Juarez, J. Campos-Alvarez, and A. Tiburcio-Silver, Thin Solid Films 517, 2497 (2009).

S. Polivtseva, I. Oja Acik, A. Katerski, A. Mere, V. Mikli, and M. Krunks, Energy Proc. 60, 156 (2014).

L.S. Price, I.P. Parkin, A.M.E. Hardy, and R.J.H. Clark, Chem. Mater. 11, 1792 (1999).

S. Sohilaa, M. Rajalakshmib, C. Ghosh, A.K. Arora, and C. Muthamizhchelvan, J. Alloys Compd. 509, 5843 (2011).

K.T.R. Reddy and P.P. Reddy, Mater. Lett. 56, 108 (2002).

S. Mushtaq, B. Ismail, M.A. Zeb, N.J. Suthan Kissinger, and A. Zeb, J. Alloys Compd. 632, 723 (2015).

H.S. Al-Salman and M.J. Abdullah, Superlattices Microst 60, 349 (2013).

A.M. Selman and Z. Hassan, Superlattices Microst 83, 549 (2015).

L.L. Cheng, M.H. Liu, M.X. Wang, S.C. Wang, G.D. Wang, Q.Y. Zhou, and Z.Q. Chen, J. Alloys Compd. 545, 122 (2012).

M. Haj Lakhdar, T. Larbi, B. Ouni, and M. Amlouk, J. Alloys Compd. 579, 198 (2013).

R. Boughalmi, A. Boukhachem, M. Kahlaoui, H. Maghraoui, and M. Amlouk, Mater. Sci. Semicond. Proc. 26, 593 (2014).

H.-Y. He, J. Fei, and J. Lu, Mater. Sci. Semicond. Proc. 24, 90 (2014).

Y. Jayasree, U. Chalapathi, and V. Sundara Raja, Thin Solid Films 537, 149 (2013).

N.R. Mathews, H.B.M. Anaya, M.A. Cortes-Jacome, C. Angeles-Chavez, and J.A. Toledo-Antonio, J. Electrochem. Soc. 157, 337 (2010).

M.S. Mahdi, K. Ibrahim, A. Hmood, N.M. Ahmed, S.A. Azzez, and F.I. Mustafa, RSC Adv. 6, 114980 (2016).

M. Vasudeva Reddy, G. Sreedevi, C. Park, R.W. Miles, and K.T. Ramakrishna Reddy, Curr. Appl. Phys. 15, 588 (2015).

P.M. Nikolic, P. Lj Miljkovic, B. Mihajlovic, and B. Lavrencic, J. Phys. C Solid Status Phys. 10, 289 (1977).

M.G. Sousa, A.F. da Cunha, and P.A. Fernandes, J. Alloys Compd. 592, 80 (2014).

H.R. Chandrasekhar, R.G. Humphreys, U. Zwick, and M. Cardona, Phys. Rev. B 15, 2177 (1977).

A. Supee, Y. Tanaka, and M. Ichimura, Mater. Sci. Semicond. Proc. 38, 290 (2015).

I.P. Parkin, L.S. Price, T.G. Hibbert, and K.C. Molloy, J. Mater. Chem. 11, 1486 (2001).

C. Wanga, K. Tanga, Q. Yanga, and Y. Qiana, Chem. Phys. Lett. 357, 371 (2002).

S.W. Shin, G.L. Agawane, M.G. Gang, A.V. Moholkar, J.-H. Moon, J.H. Kim, and J.Y. Lee, J. Alloys Compd. 526, 25 (2012).

A. Akkari, C. Guasch, N. Kamoun-Turki, and J. Tauu, J. Alloys Compd. 490, 180 (2010).

P. Jain and P. Arun, Thin Solid Films 548, 241 (2013).

S. Gedi, V.R. Minnam Reddy, C. Park, J.C. Wook, and K.T.R. Reddy, Opt. Mater. 42, 468 (2015).

S. Cheng, Y. He, and G. Chen, Mater. Chem. Phys. 110, 449 (2008).

C. Gao, H. Shen, and L. Sun, Appl. Sur. Sci. 257, 6750 (2011).

Acknowledgement

The authors are grateful to the Nano-Optoelectronics Research and Technology Laboratory (N.O.R.) of the School of Physics, Universiti Sains Malaysia, for the help extended the research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mahdi, M.S., Ibrahim, K., Hmood, A. et al. Control of Phase, Structural and Optical Properties of Tin Sulfide Nanostructured Thin Films Grown via Chemical Bath Deposition. J. Electron. Mater. 46, 4227–4235 (2017). https://doi.org/10.1007/s11664-017-5373-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-017-5373-4