Abstract

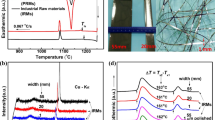

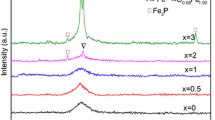

In order to develop Fe-based nanocrystalline soft magnetic alloys with high saturation magnetic flux density (B s) and good manufacturability, the effect of the Nb content on the thermal stability, microstructural evolution and soft magnetic properties of Fe78−x Si13B8Nb x Cu1 (x = 0, 1, 2 and 3) alloys were investigated. It is found that proper Nb addition is effective in widening the optimum annealing temperature range and refining the α-Fe grain in addition to enhancing the soft magnetic properties. For the representative Fe76 Si13B8Nb2Cu1 alloy, the effective annealing time can be over 60 min in the optimal temperature range of 500–600°C. FeSiBNbCu nanocrystalline soft magnetic alloys with desirable soft magnetic properties including high B s of 1.39 T, low coercivity (H c) of 1.5 A/m and high effective permeability (μ e) of 21,500 at 1 kHz have been developed. The enhanced soft magnetic performance and manufacturability of the FeSiBNbCu nanocrystalline alloys are attributed to the high activated energy for the precipitation of α-Fe(Si) and the second phase. These alloys with excellent performance have promising applications in electromagnetic fields like inductors.

Similar content being viewed by others

References

M.A. Willard, D.E. Laughlin, M.E. McHenry, D. Thoma, K. Sickafus, J.O. Cross, and V.G. Harris, J. Appl. Phys. 84, 6773 (1998).

Y. Yoshizawa, S. Oguma, and K. Yamauchi, J. Appl. Phys. 64, 6044 (1988).

M.E. McHenry and D.E. Laughlin, Acta Mater. 48, 223 (2000).

G. Herzer, IEEE Trans. Magn. 25, 3327 (1989).

G. Herzer, IEEE Trans. Magn. 26, 1397 (1990).

K. Suzuki, N. Kataoka, A. Inoue, A. Makino, and T. Masumoto, Mater. Trans. JIM 31, 743 (1990).

K. Suzuki, A. Makino, A. Inoue, and T. Masumoto, J. Appl. Phys. 70, 6232 (1991).

Z.Z. Li, A.D. Wang, C.T. Chang, Y.G. Wang, B.L. Dong, and S.X. Zhou, J. Alloys Compd. 611, 197–201 (2014).

A. Makino, IEEE Trans. Magn. 1331, 48 (2012).

G. Herzer, Handbook of Magnetic Materials, ed. K.H.J. Buschow (Weinheim: Elsevier, 1997), pp. 415–462.

M.A. Willard and M. Daniil, Handbook of Magnetic Materials, ed. K.H.J. Buschow (Weinheim: Elsevier, 2013), pp. 173–342.

J. Hu, M. Jiang, H. Qin, B. Li, and H. Kronmüller, Mater. Sci. Eng. A 449–451, 371 (2007).

M. Kopcewicz, A. Grabias, and P. Nowicki, Mater. Sci. Eng. A 226–228, 515 (1997).

N. Mattern, A. Danzig, and M. Müller, Mater. Sci. Eng. A 77–85, 194 (1994).

K. Suzuki and G. Herzer, Scripta Mater. 67, 548 (2012).

T. Bitoh, A. Makino, and A. Inoue, J. Magn. Magn. Mater. 272–276, 1445 (2004).

A.D. Wang, H. Men, B.L. Shen, G.Q. Xie, A. Makino, and A. Inoue, Thin Solid Films 519, 8283 (2011).

M. Ohta and Y. Yoshizawa, Mater. Trans. 48, 2378 (2007).

R. Alben, J.J. Becker, and M.C. Chi, J. Appl. Phys. 49, 1653 (1978).

M. Ohta and Y. Yoshizawa, J. Magn. Magn. Mater. 2220, 321 (2009).

Y. Yoshizawa and M. Ohta, J. Appl. Phys. 103, 07E722 (2008).

Z.Z. Li, A.D. Wang, C.T. Chang, Y.G. Wang, B.L. Dong, and S.X. Zhou, Intermetallics 225, 54 (2014).

T. Ozawa and K. Kanari, Thermochim. Acta 234, 41 (1994).

H.R. Lashgari, Z. Chen, X.Z. Liao, D. Chu, M. Ferry, and S. Li, Mater. Sci. Eng. A 626, 480 (2015).

A. Makino, H.M.T. Kubota, K. Yubuta, and A. Inoue, J. Appl. Phys. 105, 07308 (2009).

A. Makino, H.M.T. Kubota, K. Yubuta, and A. Inoue, IEEE Trans. Magn. 45, 4302 (2009).

K. Hono, K. Hiraga, Q. Wang, A. Inoue, and T. Sakurai, Acta Metall. Mater. 40, 2137 (1992).

T. Graf, G. Hampel, J. Korus, J. Hesse, and G. Herzer, Nanostruct. Mater. 6, 469 (1995).

K. Suzuki, J.M. Cadogan, V. Sahajwalla, A. Inoue, and T. Masumoto, Mater. Sci. Eng. A 226–228, 554 (1997).

H.S. Liu, C.H. Yin, X.X. Miao, Z.D. Han, D.H. Wang, and Y.W. Du, Mater. Sci. Technol. 24, 45 (2008).

J. Torrens-Serra, S. Roth, J. Rodriguez-Viejo, and M.T. Clavaguera-Mora, J. Non-Cryst. Solids 354, 5110 (2008).

Z. Xiang, A. Wang, C. Zhao, H. Men, X. Wang, C. Chang, and D. Pan, J. Alloys Compd. 622, 1000 (2015).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant Nos. 51541106, U1510112 and 51577123), National Scientific and Technological Support Projects (No. 2013BAE0 8B01) and the Qualified Personnel Foundation of Taiyuan University of Technology (QPFT) (No: tyutrc-201370a).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Wan, F., He, A., Zhang, J. et al. Development of FeSiBNbCu Nanocrystalline Soft Magnetic Alloys with High B s and Good Manufacturability. J. Electron. Mater. 45, 4913–4918 (2016). https://doi.org/10.1007/s11664-016-4643-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-016-4643-x