Abstract

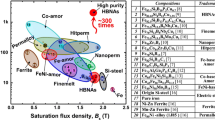

High Fe content Fe76Si13B8Nb2Cu1 alloy ribbons with excellent quality and width of 20–55 mm were successfully produced with industrial processes and raw materials, showing the superb manufacturability and impurity tolerance. It is found that impurities and ribbon width have a negligible influence on crystallization behavior, by comparing with samples prepared with high purity materials. The wide annealing time window can be over 50 min in the optimal temperature range of 500–600 °C. Besides, industrialized Fe76Si13B8Nb2Cu1 alloy ribbons exhibit outstanding magnetic properties, including high saturation magnetic flux density (Bs) of 1.39T, high effect permeability of 28.8 × 103 at 1 kHz and low coercivity of 3.5 A/m, which are equivalent to ribbon prepared with pure materials. Extreme low core losses of 0.91 W/kg at 1T and 1 kHz, 5.30 W/kg at 0.5T and 10 kHz were also obtained in ring samples. It is found that fine nanostructure and wide stripe domains are the origins of excellent magnetic properties. This alloy with excellent performance has great potential in applications of high working B and frequency devices and will also be a new reference for industrialization of nanocrystalline alloy.

Similar content being viewed by others

References

G. Herzer, Modern soft magnets: amorphous and nanocrystalline materials. Acta Mater. 61, 718–734 (2013)

Y. Yoshizawa, S. Oguma, K. Yamauchi, New Fe-based soft magnetic-alloys composed of ultrafine grain-structure. J. Appl. Phys. 64, 6044–6046 (1988)

J.M. Silveyra, V.J. Cremaschi, G. Vlasák, E. Illeková et al., Magnetostrictive behaviour of Fe73.5Si13.5B9Nb3–xMoxCu1 alloys. J. Magn. Magn. Mater. 322, 2350–2354 (2010)

Y. Han, R. Wei, A. Wang, C. Chang et al., Improvement of magnetic properties for V-substituted Fe73.5Si13.5B9Cu1Nb3–xVx nanocrystalline alloys. J. Mater. Sci. Mater. Electron. 28, 10555–10563 (2017)

K. Suzuki, N. Kataoka, A. Inoue, A. Makino et al., High saturation magnetization and soft magnetic properties of bcc Fe–Zr–B alloys with ultrafine grain structure. Mater. Trans. JIM 31, 743–746 (1990)

A. Makino, A. Inoue, T. Masumoto, Nanocrystalline soft magnetic Fe-M-B (M = Zr, Hf, Nb), Fe-M-O (M = Zr, Hf, RARE EARTH) alloys and their applications. Nanostruct. Mater. 12, 825–828 (1999)

K. Suzuki, A. Makino, N. Kataoka, High saturation magnetization and soft magnetic properties of bcc Fe–Zr–B and Fe–Zr–B–M (M = Transition Metal) alloys with nanoscale grain size. Mater. Trans. JIM 32, 93–102 (1991)

M.A. Willard, D.E. Laughlin, M.E. McHenry, D. Thoma et al., Structure and magnetic properties of (Fe0.5Co0.5)88Zr7B=Cu1 nanocrystalline alloys. J. Appl. Phys. 84, 6773–6777 (1998)

X. Liang, T. Kulik, J. Ferenc, B. Xu, Thermal and magnetic properties of Hf-containing HITPERM alloys. J. Magn. Magn. Mater. 308, 227–232 (2007)

M.A. Willard, M.Q. Huang, D.E. Laughlin, M.E. McHenry et al., Magnetic properties of HITPERM (Fe,Co)88Zr7B4Cu1 magnets. J. Appl. Phys. 85, 4421–4423 (1999)

M. Matsuura, Z. Yan, M. Nishijima, A. Makino, Role of P in nanocrystallization of Fe85Si2B8P4Cu1. IEEE Trans. Magn. 50, 1–4 (2014)

A. Makino, Nanocrystalline soft magnetic Fe–Si–B–P–Cu alloys with high B of 1.8–1.9 T contributable to energy saving. IEEE Trans. Magn. 48, 1331–1335 (2012)

T. Takahashi, K. Yoshida, Y. Shimizu, A.D. Setyawan et al., Fe–Si–B–P–C–Cu nanocrystalline soft magnetic powders with high Bs and low core loss. Aip Adv. 7, 056111 (2017)

M.E. McHenry, D.E. Laughlin, Nano-scale materials development for future magnetic applications. Acta Mater. 48, 223–238 (2000)

G. Herzer, Grain size dependence of coercivity and permeability in nanocrystalline ferromagnets. IEEE Trans. Magn. 26, 1397–1402 (1990)

F. Wan, A. He, J. Zhang, A. Wang et al., Development of FeSiBNbCu nanocrystalline soft magnetic alloys with high Bs and good manufacturability. J. Electron. Mater. 45, 4913–4918 (2016)

A. He, A. Wang, C. Chang, X. Wang, Dynamic magnetic characteristics and relaxation of Fe73.5Cu1Nb3Si15.5B7 nanocrystalline alloy under operating temperature and magnetizing frequency. J. Magn. Magn. Mater. 443, 261–266 (2017)

M.E. Mchenry, M.A. Willard, D.E. Laughlin, Amorphous and nanocrystalline materials for applications as soft magnets. Prog. Mater Sci. 44, 291–433 (1999)

H.Y. Jung, S. Yi, Enhanced glass forming ability and soft magnetic properties through an optimum Nb addition to a Fe–C–Si–B–P bulk metallic glass, Intermetallics. 18, 1936–1940 (2010)

Z. Gan, Preparation of bulk amorphous Fe–Ni–P–B–Ga alloys from industrial raw materials. Scr. Mater. 48, 1543–1547 (2003)

H.X. Li, J.E. Gao, S.L. Wang, S. Yi et al., Formation, crystallization behavior, and soft magnetic properties of FeCSiBP bulk metallic glass Fabricated using industrial raw materials. Metall. Mater. Trans. A 43, 2615–2619 (2011)

L. Xie, T. Liu, A. He, Q. Li et al., High Bs Fe-based nanocrystalline alloy with high impurity tolerance. J. Mater. Sci. 53, 1437–1446 (2017)

J. Pang, A. Wang, S. Yue, F. Kong et al., Fluxing purification and its effect on magnetic properties of high-Bs FeBPSiC amorphous alloy. J. Magn. Magn. Mater. 433, 35–41 (2017)

P. Chen, T. Liu, F. Kong, A. Wang et al., Ferromagnetic element microalloying and clustering effects in high Bs Fe-based amorphous alloys. J. Mater. Sci. Technol. 34, 793–798 (2017)

X. Liang, A. He, A. Wang, J. Pang, C. Wang et al., Fe content dependence of magnetic properties and bending ductility of FeSiBPC amorphous alloy ribbons. J. Alloy. Compd. 694, 1260–1264 (2017)

K. Hono, D.H. Ping, M. Ohnuma, H. Onodera, Cu clustering and Si partitioning in the early crystallization stage of an Fe73.5Si13.5 B9Nb3Cu1 amorphous alloy. Acta Mater. 47, 997–1006 (1999)

S. Dobák, J. Füzer, P. Kollár, Effect of a DC transverse magnetic field on the magnetization dynamics in FeCuNbSiB ribbons and derived nanostructured powder cores. J. Alloy. Compd. 651, 237–244 (2015)

J. Füzerová, J. Füzer, P. Kollár, R. Bureš et al., Complex permeability and core loss of soft magnetic Fe-based nanocrystalline powder cores. J. Magn. Magn. Mater. 345, 77–81 (2013)

A.L. Patterson, The Scherrer formula for X-ray particle size determination. Phys. Rev. 56, 978–982 (1939)

E. Lopatina, I. Soldatov, V. Budinsky, M. Marsilius et al., Surface crystallization and magnetic properties of Fe84.3Cu0.7Si4B8P3 soft magnetic ribbons. Acta Mater. 96, 10–17 (2015)

J. Zhang, F. Wan, Y. Li, A. Wang et al., Effect of surface crystallization on magnetic properties of Fe 82 Cu 1 Si 4 B 11.5 Nb 1.5 nanocrystalline alloy ribbons. J. Magn. Magn. Mater. 438, 126–131 (2017)

F. Wan, T. Liu, F. Kong, A. Wang et al., Surface crystallization and magnetic properties of FeCuSiBNbMo melt-spun nanocrystalline alloys. Mater. Res. Bull. 96, 275–280 (2017)

Acknowledgements

This work was supported by the National Key Research and Development Program of China (2017YFB0903902), and the National Natural Science Foundation of China (Grant Nos. 51601206, 51771083, 51771159), the Zhejiang Provincial Natural Science Foundation (LQ18E010006). This work was also supported by General Research Fund of Hong Kong under the grant number of CityU 102013.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Xiao, H., Wang, A., Zhao, C. et al. Industrialization of a FeSiBNbCu nanocrystalline alloy with high Bs of 1.39 T and outstanding soft magnetic properties. J Mater Sci: Mater Electron 29, 19517–19523 (2018). https://doi.org/10.1007/s10854-018-0082-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-018-0082-1