Abstract

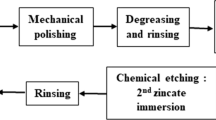

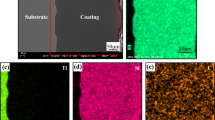

An AlN composite ceramic layer was designed and fabricated on WCu substrates by hydrolysis-assisted solidification and firing. First, the surface of WCu substrates were pre-coated with polycarbosilane/AlN ceramic layers by spinning; the layers were then fabricated by firing. The phase composition, microstructure, and element distribution of the ceramic layer and interfacial reaction layer were investigated by use of scanning electron microscopy, energy-dispersive spectroscopy and x-ray diffraction. The results showed that the ceramic layers were composed of AlN, mullite, and Al2O3. There were many nanocrystalline rods on the surface of the ceramic layers. The Cr layer prevented the WCu substrate from reacting with water vapor during firing, and the Ni layer prevented diffusion of tungsten into the Cr layer. Study of the cross section of the ceramic layer fired on the Cr/Ni/WCu substrate revealed a perfect interfacial reaction layer.

Similar content being viewed by others

References

K.N. Tu, Microelectron. Reliab. 51, 517 (2010).

H.S. Chin, K.Y. Cheong, and A.B. Ismail, Metall. Mater. Trans. B 41, 824 (2010).

S. Ye, F. Xiao, Y.X. Pan, Y.Y. Ma, and Q.Y. Zhang, Mat. Sci. Eng. R 71, 1 (2010).

S.J. Hsu, C.H. Sha, and C.C. Lee, IEEE Trans. Compon. Packag. Manuf. Technol. 3, 1625 (2013).

L. Wu, L. Song, J. Wu, L. Zhao, and C. Jiang, Ceram. Int. 33, 747 (2007).

K.R. Donner, F. Gaertner, and T. Klassen, J. Therm. Spray. Technol. 20, 299 (2011).

H.X. Li, V.S. Rudnev, X.H. Zheng, T.P. Yarovaya, and R.G. Song, J. Alloy. Compd. 462, 99 (2008).

K.H. Lin, Z.H. Xu, and S.T. Lin, J. Mater. Eng. Perform. 20, 231 (2011).

Y. Kurokawa, K. Utsumi, and H. Takamizawa, J. Am. Ceram. Soc. 71, 588 (1998).

T.B. Jackson, A.V. Virkar, K.L. More, R.B. Dinwiddie Jr., and R.A. Cutler, J. Am. Ceram. Soc. 80, 1421 (1997).

S.A. Jang and G.M. Choi, J. Am. Ceram. Soc. 76, 957 (1993).

M. Ma, Z. Liu, Y. Li, Y. Zeng, and D. Yao, J. Eur. Ceram. Soc. 33, 833 (2013).

S. Bandyopadhyay, G. Rixecker, F. Aldinger, S. Pal, K. Mukherjee, and H.S. Maiti, J. Am. Ceram. Soc. 85, 1010 (2002).

S. Novak, T. Kosmac, K. Krnel, and G. Drazic, J. Eur. Ceram. Soc. 22, 289 (2002).

J.D. Zhu, R. An, C.Q. Wang, and G.W. Wen, IEEE Trans. Compon. Packag. Manuf. Technol. 5, 182 (2015).

J. Zhang and S.H. Qi, Polym. Compos. 35, 381 (2014).

A.J. Ma, W.X. Chen, Y.G. Hou, and G. Zhang, Polym. Plast. Technol. 49, 354 (2010).

Y. Yu, Y. Guo, X. Cheng, and Y. Zhang, J. Mater. Chem. 19, 5637 (2009).

Y. Wang, H. Liu, H. Cheng, and J. Wang, Ceram. Int. 40, 12789 (2014).

M.M.S. Sanad, M.M. Rashad, E.A. Abdel-Aal, and M.F. El-Shahat, Ceram. Int. 39, 1547 (2013).

Acknowledgements

This work was supported by the National Natural Science Foundation of China, under Grant 51374084, and sponsored by grants from the Power Electronics Science and Education Development Program of the Delta Environmental and Educational Foundation (Grant No. DREK2014009). We gratefully acknowledge support from Yueqing Qianyan Alloy Material Co., Ltd., Zhejiang Province, China, which provided the W-Cu alloy material for the experiments.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhu, J., An, R., Wang, C. et al. Characterization of the Microstructure of an AlN-Mullite-Al2O3 Ceramic Layer on WCu Composite Alloy for Microelectronic Application. J. Electron. Mater. 44, 4154–4160 (2015). https://doi.org/10.1007/s11664-015-3961-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-015-3961-8