Abstract

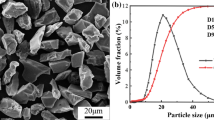

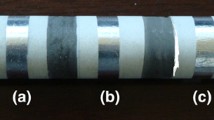

In this study, surfaces of copper plates were coated with a thick alumina layer by the plasma spray coating to fabricate a composite with a dielectric performance that made them suitable as substrates in electronic devices with high thermal dissipation. The performance of alumina dielectric layer fabricated by the plasma spray coating and traditional screen-printing process was compared, respectively. Effects of the spraying parameters and size of alumina particles on the microstructure, thickness, and the surface roughness of the coated layer were explored. In addition, the thermal resistance perpendicular to the interface of copper and alumina and the breakdown voltage across the alumina layer of the composite were also investigated. Experimental results indicated that alumina particles with 5-22 μm in diameter tended to form a thicker layer with a poorer surface roughness than that of the particles with 22-45 μm in diameter. The thermal resistance increased with the surface roughness of the alumina layer, and the breakdown voltage was affected by the ambient moisture, the microstructure and the thickness of the layer. The optimal parameters for plasma spray coating were an alumina powder of particles size between 22 and 45 μm, a plasma power of 40 kW, a spraying velocity of 750 m/s, an argon flow rate of 45 L/min, a spraying distance of 140 mm, and a spraying angle of 90°. It can be concluded that an alumina layer thickness of 20 μm provided a low surface roughness, low thermal resistance, and highly reliable breakdown voltage (38 V/μm).

Similar content being viewed by others

References

T.F. Lemczyk, B. Mack, J.R. Culham, and M.M. Yovanovich, PCB Trace Thermal Analysis and Effective Conductivity, Proceedings—IEEE Semiconductor Thermal and Temperature Measurement Symposium, Phoenix, 1991, p 15-22

J. Petroski, Spacing of High-Brightness LEDs on Metal Substrate PCB’s for Proper Thermal Performance, Thermomechanical Phenomena in Electronic Systems—Proceedings of the Inter Society Conference, Vol 2, 2004, p 507-514

S.D. Pascoli, P.E. Bagnoli, and C. Casarosa, Thermal Analysis of Insulated Metal Substrates for Automotive Electronic Assemblies, Microelectron. J., 1999, 30, p 1129–1135

S.I. Asai, M. Funaki, H. Sawa, and K. Kato, Fabrication of an Insulated Metal Substrate (IMS), Having an Insulating Layer with a High Dielectric Constant, IEEE Trans. Comp. Hybrids Manuf. Technol., 1993, 16(5), p 499–504

C. Marc, N. James, and A. Robert, Power Modules with IMS Substrates for Automotive Application, IEEE Vehicular Technology Conference, Birmingham, Vol 4, 2002, p 2056-2063

H.M. Cho and H.J. Kim, Metal-Core Printed Circuit Board with Alumina Layer by Aerosol Deposition Process, IEEE Electr. Device Lett., 2008, 29(9), p 991–993

F. Miyashiro, N. Iwase, A. Tsuge, F. Ueno, M. Nakahashi, and T. Takahashi, High Thermal Conductivity Aluminum Nitride Ceramic Substrates and Packages, IEEE Trans. Comp. Hybrids Manuf. Technol., 1990, 13(2), p 313–319

F. Xiang, H. Wang, M. Zhang, X. Sun, and X. Yao, Preparation and Dielectric Tunability of Bismuth-Based Pyrochlore Dielectric Thick Films on Alumina Substrates, Ceram. Int., 2008, 34(4), p 925–928

M. Darveniza, Electrical Breakdown of Air Between Insulated Conductors, Proceedings of the IEEE International Conference on Properties and Applications of Dielectric Materials, Vol 2, 2002, p 615-620

JCPDS—International Centre for Diffraction Data, #37-1462, #04-0836, Vol 2.3, 2000

Y. Zeng, S.W. Lee, and C.X. Ding, Plasma Spray Coatings in Different Nano-size Alumina, Mater. Lett., 2002, 57, p 495–501

J.S. Reed, Principles of Ceramics Processing, John Wiley & Sons, Inc, New York, 1995, p 576–578

O. Sarikaya, Effect of Some Parameters on Microstructure and Hardness of Alumina Coatings Prepared by the Air Plasma Spraying Process, Surf. Coat. Technol., 2005, 190(2–3), p 388–393

R. Suryanarayanan, Plasma Spraying Theory and Applications, World Scientific Publishing, Singapore, 1993, p 103–114

H.J. Kim, S. Odoul, C.H. Lee, and Y.G. Kweon, The Electrical Insulation Behavior and Sealing Effects of Plasma-Sprayed Alumina Titania Coatings, Surf. Coat. Technol., 2001, 140, p 293–301

X.S. Ning, Y. Lin, W. Xu, R. Peng, H. Zhou, and K. Chen, Development of a Directly Bonded Aluminum/Alumina Power Electronic Substrate, Mater. Sci. Eng. B, 2003, 99, p 479–482

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lin, K.H., Xu, Z.H. & Lin, S.T. A Study on Microstructure and Dielectric Performances of Alumina/Copper Composites by Plasma Spray Coating. J. of Materi Eng and Perform 20, 231–237 (2011). https://doi.org/10.1007/s11665-010-9678-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-010-9678-1