Abstract

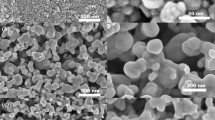

In printed electronics applications, specific resistances of conductive lines are critical to the performance of the devices. The specific resistance of a silver (Ag) nanoparticle electrode is affected by surface morphology of the layered nanoparticles which were sintered by the heat treatment after printing. In this work, the relationship between surface morphology and specific resistance was investigated with various sintering temperatures and various layer thicknesses of Ag nanoparticle ink. Ag nanoparticles with an average size of approximately 50 nm were spin-coated on Eagle XG glass substrates with various spin speed to change the layer thickness of Ag nanoparticles from 200 nm to 900 nm. Coated Ag nanoparticle layers were heated from 150°C to 450°C for 30 min in a furnace. The result showed that higher sintering temperature produces larger grains in an Ag layer and decreases specific resistance of the layer, but that the maximum allowable heating temperature is limited by the thickness of the layer. When grain size exceeded the thickness of the layer, the morphology of the Ag nanoparticles changed to submicron-sized islands and the Ag layers did not have electrical conductivity any more.

Similar content being viewed by others

References

J.W. Kang, W.I. Jeong, J.J. Kim, H.K. Kim, D.G. Kim, and G.H. Lee, High-performance flexible organic light-emitting diodes using amorphous indium zinc oxide anode. Electrochem. Solid-State Lett. 10, 75 (2007).

L. Hou, F. Huang, W. Zeng, J. Peng, and Y. Cao, High- efficiency inverted top-emitting polymer light-emitting diodes. Appl. Phys. Lett. 87, 153509 (2005).

V. Shamanna, S. Das, Z. Celik-Butler, and K.L. Lawrence, Micromachined integrated pressure–thermal sensors on flexible substrates. J. Micromech. Microeng. 16, 1984 (2006).

F. Jiang, G.B. Lee, Y.C. Tai, and C.M. Ho, A flexible micromachine-based shear-stress sensor array and its application to separation-point detection. Sens. Actuators A 79, 194 (2000).

S.A. Day, D.P. Butler, and Z. Celik-Bulter, Micromachined infrared bolometers on flexible polyimide substrates. Sens. Actuators A 118, 49 (2005).

S. Tung, S.R. Witherspoon, L.A. Roe, A. Silano, D.P. Maynard, and N. Ferraro, AMEMS-based flexible sensor and actuator system for space inflatable structures. Smart Mater. Struct. 10, 1230 (2001).

K.J. Lee, B.H. Jun, T.H. Kim, and J. Joung, Direct synthesis and inkjetting of silver nanocrystals toward printed electronics. Nanotechnology 17, 2424 (2006).

D. Kim, S. Jeong, B.K. Park, and J. Moon, Direct writing of silver conductive patterns: Improvement of film morphology and conductance by controlling solvent compositions. Appl. Phys. Lett. 89, 264101 (2006).

T.H.J. Van Osch, J. Perelaer, A.W.M. De Laat, and U.S. Schubert, Inkjet printing of narrow conductive tracks on untreated polymeric substrates. Adv. Mater. 20, 343 (2008).

W.D. Kingery, H.K. Bowen, and D.R. Uhlmann, Introduction to Ceramics (New York: Wiley, 1976).

F.F. Lange, Sinterability of agglomerated powders. J. Am. Ceram. Soc. 67, 83 (1984).

C.J. Brinker and G.W. Scherer, Sol–Gel Science (San Diego, CA: Academic, 1990).

K.S. Chou, K.C. Huang, and H.H. Lee, Fabrication and sintering effect on the morphologies and conductivity of nano-Ag particle films by spin coating method. Nanotechnology 16, 779 (2005).

J.W. Park and S.G. Baek, Thermal behavior of direct-printed lines of silver nanoparticles. Scr. Mater. 55, 1139 (2006).

Y.J. Moon, H. Kang, K. Kang, J.Y. Hwang, J.H. Lee, and S.J. Moon, Effect of laser intensity on the characteristics of inkjet-printed silver nanoparticles during continuous laser sintering. J. Nanosci. Nanotechnol. 14, 8631 (2014).

J. Perelaer, A.W.M. de Laat, C.E. Hendriks, and U.S. Schubert, Inkjet-printed silver tracks: low temperature curing and thermal stability investigation. J. Mater. Chem. 18, 3209 (2008).

B.J. Norris, J. Anderson, J.F. Wagner, and D.A. Keszler, J. Phys. D. 36, L105 (2003).

J.H. Lim, J.H. Shim, J.H. Choi, J.H. Joo, K. Park, H.S. Jeon, M.R. Moon, D.G. Jung, H.S. Kim, and H.J. Lee, Solution-processed InGaZnO-based thin film transistors for printed electronics applications. Appl. Phys. Lett. 95, 012108 (2009).

J.Y. Hwang and S.J. Moon, The characteristic variations of inkjet-printed silver nanoparticle ink during furnace sintering. J. Nanosci. Nanotechnol. 13, 6145 (2013).

K.S. Moon, H. Dong, R. Maric, S. Pothukuchi, A. Hurt, y. Li, and C.P. Wang, Thermal behavior of silver nanoparticles for low temperature interconnect applications. J. Electron. Mater. 34, 168 (2005).

J.S. Kang, J. Ryu, H.S. Kim, and H.T. Hahn, Sintering of inkjet printed silver nanoparticles at room temperature using intense pulsed light. J. Electron. Mater. 40, 2268 (2011).

P. Zeng, S. Zajac, P.C. Clapp, and J.A. Rifkin, Nanoparticle sintering simulations. Mater. Sci. Eng. A 252, 301 (1998).

M.J. Mayo, Processing of nanocrystalline ceramics from ultrafine particles. Int. Mater. Rev. 41, 85 (1996).

B. Ingham, T.H. Lim, C.J. Dotzler, A. Henning, M.F. Toney, and R.D. Tilley, How nanoparticles coalesce: an in␣situ study of Au nanoparticle aggregation and grain growth. Chem. Mater. 23, 3312 (2011).

D.W. Richerson, Modern Ceramic Engineering: Properties, Processing and Use in Design, 2nd ed. (New York: Marcel Dekker, 1992).

M.N. Rahaman, Ceramic Processing and Sintering, 2nd ed. (New York: Marcel Dekker, 2003).

Acknowledgement

This work was supported by a grant from the Industrial Source Technology Development Program (Grant 10041041) of the Ministry of Trade, Industry and Energy of Korea.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Moon, Y.J., Kang, H., Kang, K. et al. Effect of Thickness on Surface Morphology of Silver Nanoparticle Layer During Furnace Sintering. J. Electron. Mater. 44, 1192–1199 (2015). https://doi.org/10.1007/s11664-015-3639-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-015-3639-2