Abstract

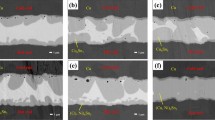

Sputtered Ti/Ni(V)/Cu under bump metallization (UBM) is widely used in flip chip technology because the metals are nonmagnetic and the consumption of the Ni(V) layer is low. It is noted that V does not react with solders and intermetallic compounds (IMC) during reflow and aging; however, a Sn-patch forms in the Ni(V) layer, and the Sn-patch growth may cause the IMCs to detach from the interface of solder joints. In this study, Sn-3.0Ag-0.5Cu solder was reflowed on Ti/Ni(V)/Cu UBM with different Cu thicknesses at 250°C for 60 s, and then aged at 150°C for various periods of time. It was revealed that the Sn-patch growth could be controlled by increasing the Cu thickness in the Ti/Ni(V)/Cu UBM. A feasible approach to suppress Sn-patch formation after reflow and aging is discussed.

Similar content being viewed by others

References

P.A. Totta and R.P. Sopher, IBM J. Res. Dev. 13, 226 (1969).

J.H. Lau, Flip Chip Technologies (New York: McGraw-Hill, 1996), p. 123.

D.R. Frear, J.W. Wang, J.K. Lin, and C. Zheng, JOM 53, 38 (2001).

C.Y. Liu, K.N. Tu, T.T. Sheng, C.H. Tung, D.R. Frear, and P. Elenius, J. Appl. Phys. 87, 750 (2000).

C.H. Tung, P.S. Teo, and C. Lee, IEEE Trans. Dev. Mater. Reliab. 5, 212 (2005).

F. Zhang, M. Li, C.C. Chum, and K.N. Tu, J. Mater. Res. 17, 2757 (2002).

A.T. Wu and F. Hua, J. Mater. Res. 22, 735 (2007).

G.Y. Jang, J.G. Duh, H. Takahashi, S.W. Lu, and J.C. Chen, J. Electron. Mater. 35, 1745 (2006).

G.Y. Jang and J.G. Duh, J. Electron. Mater. 35, 2061 (2006).

K.J. Wang and J.G. Duh, J. Electron. Mater. 38, 2534 (2009).

K.J. Wang, Y.Z. Tsai, J.G. Duh, and T.Y. Shih, J. Mater. Res. 24, 2638 (2009).

S.W. Chen and C.C. Chen, J. Electron. Mater. 36, 1121 (2007).

K.J. Wang, J.G. Duh, B. Sykes, and D. Schade, J. Electron. Mater. 39, 2558 (2010).

K.N. Tu and K. Zeng, Mater. Sci. Eng. R Rep. 34, 1 (2001).

K. Zeng, V. Vuorinen, and J.K. Kivilahti, IEEE Trans. Electron. Packag. Manuf. 25, 162 (2002).

C.E. Ho, S.C. Yang, and C.R. Kao, J. Mater. Sci. Mater. Electron. 18, 155 (2007).

J.W. Yoon, B.I. Noh, B.K. Kim, C.C. Shur, and S.B. Jung, J. Alloys Compd. 486, 142 (2009).

C.Y. Li and J.G. Duh, J. Mater. Res. 20, 3118 (2005).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, KJ., Duh, JG. Suppressing Sn-Patch Growth in Ti/Ni(V)/Cu Under Bump Metallization with Sn-Ag-Cu Solder After Reflow and Aging. J. Electron. Mater. 41, 757–762 (2012). https://doi.org/10.1007/s11664-012-1925-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-012-1925-9