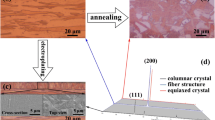

Cu6Sn5 and Cu3Sn are easily formed at the interface between Sn and Cu during reflow and aging processes. Thick Cu-Sn compounds at the interface become brittle, reducing the mechanical strength of solder joints and increasing the consumption of under bump metallization (UBM). It is noted that intermetallic compound (IMC) growth and substrate consumption are affected by factors such as substrate fabrication, substrate orientation, and substrate microstructure. In this study, to determine the effects of substrate grain size on IMC growth and substrate consumption, pure Sn solder was reflowed on annealed Cu substrates with different grain sizes at 250°C for 30 s to 600 s. It was revealed that Cu substrates with smaller grain sizes exhibited reduced IMC growth. In addition, the interdiffusion coefficients of Cu6Sn5 and Cu3Sn were decreased for the Cu substrate with the smaller grain size. The influence of the Cu substrate grain size on IMC growth and substrate consumption is discussed.

Similar content being viewed by others

References

M.G. Cho, S.K. Seo, and H.M. Lee, J. Alloys Compd. 474, 510 (2009).

K.J. Puttlitz and K.A. Stalter, Handbook of Lead-Free Solder Technology for Microelectronic Assemblies (New York: Marcel Dekker, 2004), p. 239.

S.K. Kang, P.A. Lauro, D.Y. Shin, D.W. Henderson, and K.J. Puttlitz, IBM J. Res. Dev. 49, 607 (2005).

I.E. Anderson and J.L. Harringa, J. Electron Mater. 33, 1485 (2004).

J.Y. Kim and J. Yu, Appl. Phys. Lett. 92, 092109 (2008).

M.J. Rizvi, Y.C. Chan, C. Bailey, H. Lu, and M.N. Islam, J. Alloys Compd. 407, 208 (2006).

A. Sharif and Y.C. Chan, Thin Solid Films 504, 431 (2006).

K.S. Kim, S.H. Huh, and K. Suganuma, Microelectron. Reliab. 43, 259 (2002).

S.K. Kang, D. Leonard, D.Y. Shin, L. Gignac, and D.W. Henderson, J. Electron Mater. 35, 479 (2006).

F. Gao and T. Takemoto, J. Alloys Compd. 421, 283 (2006).

H.T. Lee and Y.H. Lee, Mater. Sci. Eng. A 419, 172 (2006).

T. Laurila, V. Vuorinen, and J.K. Kivilahti, Mater. Sci. Eng. R 49, 1 (2005).

H.F. Zou, H.J. Yang, and Z.F. Zhang, Acta Mater. 56, 2649 (2008).

Y. Li, J. Chen, C. Lazik, P. Wang, L. Yang, J. Yu, T. Sun, and E. Ko, J. Mater. Res. 20, 2622 (2005).

H.K. Kim and K.N. Tu, Appl. Phys. Lett. 67, 2002 (1995).

J.H. Shim, C.S. Oh, B.J. Lee, and D.N. Lee, Z. Metallkd. 87, 205 (1996).

U.R. Kattner and W.J. Boettinge, J. Electron Mater. 23, 603 (1994).

D.A. Porter and K.E. Easterling, Phase Transformations in Metals and Alloys (Cheltenham: Nelson Thornes, 1992), p. 173.

S.F. Cogan, S. Kwon, J.D. Klein, and R.M. Rose, J. Mater. Sci. 19, 497 (1984).

K. Zeng, R. Stierman, T.C. Chiu, D. Edwards, K. Ano, and K.N. Tu, J. Appl. Phys. 97, 024508 (2005).

K.H. Prakash and T. Sritharan, Acta Mater. 49, 2481 (2001).

M. Onishi and H. Fujibuchi, Trans. J. Inst. Metal. 16, 539 (1975).

J.O. Suh, K.N. Tu, G.V. Lutsenko, and A.M. Gusak, Acta Mater. 56, 1075 (2008).

J. Görlich, G. Schmitz, and K.N. Tu, Appl. Phys. Lett. 86, 053106 (2005).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, JM., Wang, KJ. & Duh, JG. Cu Substrates with Different Grain Sizes. J. Electron. Mater. 40, 1549–1555 (2011). https://doi.org/10.1007/s11664-011-1646-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-011-1646-5