Sn-Ag-eutectic-based solders are replacing Sn-Pb eutectic solders in the electronics industry. The current paper extends the recently developed approach based on phase transformation theory, micromechanics, and fracture mechanics to treat fatigue crack nucleation and propagation for steels and alloys to predict fatigue crack propagation in solder alloys. To verify the proposed method, fatigue experiments were conducted on Sn-3.5Ag solder alloys. Finite element analysis is performed to predict the stress intensity factor range ΔK and the required energy U to increase the crack by a unit area. Unified creep-plasticity theory and a cohesive zone model are incorporated to predict the creep and hysteresis effects on fatigue crack propagation in solder and the interfacial behavior between the solder alloy and the intermetallic layer, respectively. With U determined numerically, the predicted fatigue crack propagation rate using phase transformation theory is compared with experimental data for Sn-3.5Ag and Sn-37Pb eutectic solders. Reasonable agreement between theoretical predictions and experimental results is obtained.

Similar content being viewed by others

Abbreviations

- ΔA :

-

area of crack

- A :

-

material constant

- da/dN :

-

area of crack growth per cycle

- b :

-

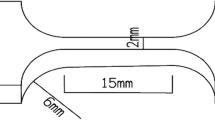

specimen thickness

- B :

-

a dimensionless constant

- C :

-

matrix of the elastic constants

- d :

-

drag strength

- D :

-

material constant

- E :

-

Young’s modulus

- G :

-

Shear modulus

- J :

-

J-integral value

- k :

-

universal gas constant

- ΔK :

-

stress intensity factor range

- ΔK c :

-

critical stress intensity factor

- l, m, n :

-

material constant

- N :

-

direction of the deformation loading

- Q :

-

apparent activation energy

- R :

-

radius of the yield space

- S :

-

deviatoric stress tensor

- S v :

-

viscous overstress

- T :

-

temperature

- U :

-

the energy to propagate a unit fatigue crack surface

- ΔW :

-

the energy required to increase the crack area by ΔA

- ΔW 1a :

-

the gain in energy per unit area due to loss of defects as the crack advances ΔA under constant ΔK (the stress intensity range)

- ΔW 1b :

-

the energy per unit area consumed by the extension of the plastic zone

- ΔW 2 :

-

the stored elastic energy

- ΔW 3 :

-

the plastic work per unit area transferred to heat for each cyclic loading step

- α :

-

deviatoric back stress

- β :

-

material constant

- γ T :

-

total surface energy per unit area of crack

- μ :

-

material constants

- σ :

-

maximum stress in the cycle

- σ y :

-

yield stress

- ν :

-

Poisson’s ratio

- \( {\dot {{\varvec \upvarepsilon}}} \) :

-

total strain rate

- \({\dot {{\varvec \upvarepsilon}}}^{{\rm{in}}} \) :

-

inelastic strain rate

- Θ :

-

diffusivity term

- χ :

-

coefficient of thermal expansion

- η :

-

material constants

References

P.C. Paris, Fatigue Frac. Eng. Mater. Struct. 21, 535 (1998)

L. Leicht, A. Skipor, Int. J. Microcircuits Electron. Pkg. 22, 57 (1999)

X. Liu, V.K. Sooklal, M.A. Verges, M.C. Larson, Microelectron. Reliability 46, 1128 (2006)

P. Towashiraporn, G. Subbarayan, C.S. Desai, Int. J. Solids Struct. 42, 4468 (2005)

D. Shangguan, Solder. Surf. Mount Tech. 11, 27 (1999)

D.R. Frear, J.W. Jang, J.K. Lin, C. Zhang, JOM 53, 28 (2001)

D.H. Kim, P. Elenius, S. Barrett, IEEE Trans. EPM 25, 84 (2002)

A.F. Bower, D. Craft, Fatigue Frac. Eng. Mater. Struct. 21, 611 (1998)

H.N. Hashemi, P. Yang, Int. J. Fatigue 23, 325 (2001)

M. Erinc, P.J.G. Schreurs, G.Q. Zhang, M.G.D. Geers, J. Mater. Sci. 16, 700 (2005)

M.E. Fine, Scrip. Mater. 42, 1007 (2000)

P.B. Shrikant, M.E. Fine, Mater. Sci. Eng. A 314, 90 (2001)

P.K. Liaw, S.I. Kwun, M.E. Fine, Metal. Trans. A 12, 49 (1981)

J.K. Shang, Q.L. Zeng, L. Zhang, Q.S. Zhu, J. Mater. Sci. 18, 211 (2007)

C. Kanchanomai, Y. Mutoh, Fatigue Frac. Eng. Mater. Struct. 30, 443 (2007)

Y. Yao, M.E. Fine, L.M. Keer, Int. J. Frac. FRAC799 2007 (in press and to be available online)

C. Kanchanomai, W. Limtrakarn, Y. Mutoh, Mech. Mater. 37, 1166 (2005)

ASTM: E647, ASTM Standards 03.01, 562 (1998)

T. Mura, Micromechanics of Defects in Solids, 2nd ed. (Netherlands: Martinus Nijhoff, 1991)

N.W. Klingbeil, Int. J. Fatigue 25, 117 (2003)

M.L. Benzeggagh, M. Kenane, Composites Sci. Tech. 56, 439 (1996)

D.L. McDowell, M.P. Miller, D.C. Brooks, Fatigue Electro. Mater. ASTM STP 1153, 42 (1994)

S. Wen, L.M. Keer, H. Mavoori, J. Electron. Mater. 30, 1190 (2001)

J. Lubliner, Int. J. Non-linear Mech. 7, 237 (1972)

W. Prager, J. Appl. Mech., Trans. Am. Soc. Mech. Eng. 23, 493 (1956)

S. Wen (Ph.D. dissertation, Northwestern University, 2001)

F. Wang, L.M. Keer, S. Vaynman, S. Wen, IEEE Trans. CPT 27, 718 (2004)

S. Vaynman, S.A. McKeown, IEEE Trans. CHMT 16, 317 (1993)

S. Vaynman, A. Zubelewicz, Welding J. 69, 395 (1990)

H. Mavoori (Ph.D. dissertation, Northwestern University, 1996)

R. Darveaux, K. Banerji, IEEE Trans. CHMT 15, 1013 (1992)

NIST Database for Solder Properties, Release 4.0 (2002)

Acknowledgement

The authors acknowledge support by Semiconductor Research Corporation (SRC) Contract No. 1393.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yao, Y., Vaynman, S., Keer, L. et al. Energy-Based Micromechanics Analysis on Fatigue Crack Propagation Behavior in Sn-Ag Eutectic Solder. J. Electron. Mater. 37, 339–346 (2008). https://doi.org/10.1007/s11664-007-0356-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-007-0356-5