Abstract

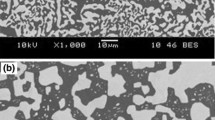

Creep behavior of the lead-free Sn-5%Sb solder alloy was studied by long-time Vickers indentation testing at room temperature. Four different conditions of the material were examined. These were unhomogenized cast (UC), homogenized cast (HC), unhomogenized wrought (UW), and homogenized wrought (HW) conditions. Based on the steady-state power-law creep relationship, the stress exponents were determined through different methods of analysis, and in all cases, the calculated exponents were in good agreement. The stress exponent values of about 5 and 12, depending on the processing route of the material, are very close to those determined by room-temperature conventional creep testing of the same material reported in the literature. For the HW condition, the n value of about 5 together with a very fine grain size of 4.5 µm and a high volume fraction of second-phase particles of 8.6% may suggest that dislocation climb is the creep mechanism. For all other conditions with different grain sizes and second-phase volume fractions, however, the high n value of 12 implies that the operative creep mechanism is dislocation creep, which is independent of grain size.

Similar content being viewed by others

References

K.L. Murty, F.M. Haggag, and R.K. Mahidhara, J. Electron. Mater. 26, 839 (1997).

P.T. Vianco and D.R. Frear, JOM 45(7), 14 (1993).

R.J. McCabe and M.E. Fine, Metall. Mater. Trans. A 33A, 1531 (2002).

H. Mavoori, JOM 52(6), 29 (2000).

M.H.N. Beshaie, S.K. Habib, A.M. Yassein, G. Saad, and M.H. Hasab El-Naby, Cryst. Res. Technol. 34, 119 (1999).

R.J. McCabe and M.E. Fine, J. Electron. Mater. 31, 1276 (2002).

N. Wade, K. Wu, J. Kuni, S. Yamada, and K. Miyahara, J. Electron. Mater. 30, 1228 (2001).

M. Fujiwara and M. Otsuka, Mater. Sci. Eng. A319–A321, 929 (2001).

R. Mahmudi, R. Roumina, and B. Raeisinia, Mater. Sci. Eng. A382, 15 (2004).

T.R.G. Kutty, T. Jarvis, and C. Ganguly, J. Nucl. Mater. 246, 189 (1997).

R. Roumina, B. Raeisinia, and R. Mahmudi, Scripta Mater. 51, 497 (2004).

T.R.G. Kutty, C. Ganguly, and D.H. Sastry, Scripta Mater. 34, 1833 (1996).

A. De La Torre, P. Adeva, and M. Aballe, J. Mater. Sci. 26, 4351 (1991).

G. Sharma, R.V. Ramanujan, T.R.G. Kutty, and G.P. Tiwari, Mater. Sci. Eng. A278, 106 (2000).

F. Yang and J.C.M. Li, Mater. Sci. Eng, A201, 40 (1995).

A. Juhasz, P. Tasnadi, P. Szasvari, and I. Kovacs, J. Mater. Sci. 21, 3278 (1986).

M.J. Mayo and W.D. Nix, Acta Metall. 36, 2183 (1988).

K.L. Murty, Mater. Sci. Eng. A14, 169 (1974).

T.T. Fang, R.R. Cola, and K.L. Murty, Metall. Trans. A 17A, 1447 (1986).

S. Devaki Rani and G.S. Murthy, Mater. Sci. Technol. 20, 403 (2004).

I. Dutta, C. Park, and S. Choi, Mater. Sci. Eng. A379, 401 (2004).

G. Cseh, N.Q. Chinh. P. Tasnadi, and A. Juhasz, J. Mater. Sci. 32, 5107 (1997).

P.M. Sargent and M.F. Ashby, Mater. Sci. Technol. 8, 594 (1992).

B.N. Lucas and W.C. Oliver, Metall. Mater. Trans. A 30A, 601 (1999).

T.G. Langdon, Mater. Sci. Eng. A283, 266 (2000).

T.O. Mulhearn and D. Tabor, J. Inst. Met. 89, 7 (1960).

A. Juhasz, P. Tasnadi, and I. Kovacs, J. Mater. Sci. Lett. 5, 35 (1986).

G.E. Dieter, Mechanical Metallurgy, 3rd ed (New York: McGraw-Hill, 1986), pp. 191–192.

G. Cseh, J. Bar, H.J. Gudladt, J. Lendvai, and A. Juhasz, Mater. Sci. Eng. A272, 145 (1999).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Geranmayeh, A.R., Mahmudi, R. Room-temperature indentation creep of lead-free Sn-5%Sb solder alloy. J. Electron. Mater. 34, 1002–1009 (2005). https://doi.org/10.1007/s11664-005-0087-4

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s11664-005-0087-4