Abstract

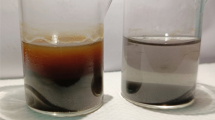

The interfacial phenomena between carbonaceous materials such as graphite, coke, coal, and char and Fe-C-S melts are important due to the extensive use of these materials in iron processing furnaces. However, the understanding of the interfacial phenomena between these kinds of carbonaceous materials and molten iron alloys is far from complete. In this study, graphite was selected as the solid carbonaceous material because its atomic structure has been well established. The sessile drop method was adopted in this investigation to measure the contact angle between solid graphite and molten iron and to study the interfacial phenomena. The influence of carbon and sulfur content in Fe-C-S melts on the wettability of solid graphite has been investigated at 1600 °C. The melt carbon content was in the range of 0.13 to 2.24 wt pct, and the melt sulfur content was in the range of 0.05 to 0.37 wt pct. X-ray energy-dispersive spectrometer (EDS) analysis was conducted on an HITACHI S-4500 scanning electron microscope to detect composition distribution at the interfacial region. It was found that contact of solid graphite with Fe-C-S melts will result in a nonequilibrium reactive wetting. It involved carbon transfer from the solid to the liquid and iron transfer from the liquid to the solid. The Fe-C-S melts exhibited relatively poor wetting when the reactions were absent. The mass transfer between solid graphite and Fe-C-S melts was observed to strongly enhance the wetting phenomena. It is proposed that the decrease of system free energy corresponding to the mass transfer reactions strongly influences the formation of the interface region and results in the progressive spreading of the wetting line. The composition and thickness of the graphite/iron interfacial layer was dependent on the intensity of mass transfer across the interface. The resulting change in the interfacial energy γ ls is a strong function of mass transfer, and it varies in accordance with time of contact. The influence of carbon content on the wetting phenomena could only be seen at in the initial stages, whereas the influence of sulfur on the wettability was found when the system approached equilibrium. Therefore, the interfacial tension in its equilibrium condition at the graphite/Fe-C-S melt interface was determined only by the extent of sulfur adsorption at this interface.

Similar content being viewed by others

References

T. Young: Phil. Trans. R. Soc. London, 1805, vol. 95, p. 65.

A. Dupre: Theorie Mecanique de la Chaleur, 1st ed., Gauthier-Villars Readex Microprint, Paris, 1869, p. 368.

A. Aksay, C.E. Hoge, and J.A. Pask: J. Phys. Chem., 1974, vol. 78 (12), pp. 1178–83.

J.V. Naidich: Progr. Surf. Membr. Sci., Academic Press, New York, NY, 1981, vol. 14, pp. 353–485.

J.V. Naidich, V.M. Perevertaylo, and O.B. Loginova: Russ. Metall., 1979, vol. 4, pp. 33–37.

P.R. Chidambaram, G.R. Edwards, and D.L. Olson: Metall. Trans. B, 1992, vol. 23B, pp. 215–22.

V. Laurent: Ph.D. Thesis, Institut National Polytechnique de Grenoble, Grenoble, France, 1988.

D. Chatain, L. Condurier, A. Steinchen, and N. Eustathopoulos: Interface in New Materials, Elsevier Applied Science, Amsterdam, 1991, pp. 210–18.

L. Espie, B. Drevet, and N. Eustathopoulos: Metall. Mater. Trans. A, 1994, vol. 25A, pp. 599–605.

B.J. Keene: Slag Atlas, 2nd edition, Verlag Stahleisen GmbH, Duesseldorf, 1995, pp. 513–39.

I. Jimbo and A.W. Cramb: Iron Steel Inst. Jpn. Int., 1992, vol. 32 (1), pp. 26–35.

Y.V. Naidich and N.F. Grigorenko: J. Mater. Sci., 1992, vol. 27, pp. 3092–97.

L. Jimbo, A. Sharan, and A.W. Cramb: Steelmaking Conf. Proc., 1993, pp. 485–94.

P. Kozakevitch and G. Urbain: Mem. Sci. Rev. Metall., 1961, vol. 58 (2), pp. 139–42.

G. Pual: Gissereiforschung, 1971, vol. 23 (1), pp. 13–17 (in English).

R.D. Burdon: Surface Tension and the Spreading of Liquid, 2nd ed., Cambridge University Press, London, 1949, pp. 34–39.

R. Defay, I. Prigogine, A. Bellemans, and D.H. Everett: Surface Tension and Adsorption, 1st ed., Longmans, London, 1966, pp. 210–12.

H.J. Fecht: J. Phys., 1988, Coll. C5, Suppl. 10, Tome 49, pp. 25–27.

Harkins: The Physical Chemistry of Surface Films, 1st ed., Reinhold, New York, NY, 1952, pp. 21–22.

S.K. Rhee: J. Am. Ceram. Soc., 1972, vol. 55 (6), pp. 300–03.

G.R. Belton: Metall. Trans. B, 1976, vol. 7B, pp. 35–42.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Wu, C., Sahajwalla, V. Influence of melt carbon and sulfur on the wetting of solid graphite by Fe-C-S melts. Metall Mater Trans B 29, 471–477 (1998). https://doi.org/10.1007/s11663-998-0126-7

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11663-998-0126-7