Abstract

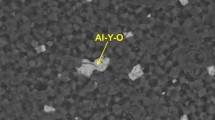

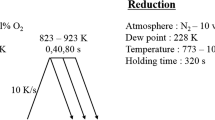

The wettability between a Si–S steel with 0.2 wt pct sulfur and 0~3.5 wt pct silicon and a CaO substrate was investigated using a sessile drop method at 1550 °C. The equilibrium contact angle between the Si–S steel and the CaO substrate was 95, 136, 142 and 142 deg when the content of silicon in the steel was 0, 1.4, 2.8, and 3.5 wt pct, respectively. When there was no silicon in the steel, the steel hardly reacted with the CaO substrate. However, when the steel contained > 1 wt pct silicon, a reaction layer composed of CaS and 2CaO·SiO2 was generated at the interface between the molten steel and the substrate. Besides, the thickness of the reaction layer increased from 0 to 36 μm with the silicon content in the steel increasing from 0 to 2.8 wt pct, because the dissolved oxygen was reduced by silicon. However, when the silicon content increased to 3.5 wt pct, the thickness of the reaction layer reversely decreased, which was attributed to the prevention of the sulfur diffusion in the dense solid state reaction layer.

Similar content being viewed by others

References

Y. Taniguchi and S. Seetharaman: Metall. Mater. Trans. B, 2012, vol. 43B, pp. 587–97.

K. Michalek, L. Čamek, K. Gryc, M. Tkadlečková, T. Huczala, and V. Troszok: Mater. Technol., 2012, vol. 46(3), pp. 297–303.

S.-C. Duan, X. Shi, M.-C. Zhang, B. Li, W.-S. Yang, F. Wang, H.-J. Guo, and J. Guo: Metall. Mater. Trans. B, 2020, vol. 51B, pp. 353–64.

M. Numata and Y. Higuchi: ISIJ Int., 2012, vol. 52, pp. 2019–25.

J. Yang, M. Kuwabara, T. Sakai, N. Uchida, Z. Liu, and M. Sano: ISIJ Int., 2007, vol. 47, pp. 418–26.

R. Tsujino, J. Nakashima, M. Hirai, and Y. Yamada: ISIJ Int., 1989, vol. 29, pp. 92–95.

Y. Taniguchi, N. Sano, and S. Seetharaman: ISIJ Int., 2009, vol. 49, pp. 156–63.

G.H. Park, Y.B. Kang, and J.H. Park: ISIJ Int., 2011, vol. 51, pp. 1375–82.

X. Hao, X. Wang, and W. Wang: Steel Res. Int., 2015, vol. 86, pp. 1455–60.

Q. Shu, Q. Luo, L. Wang, and K. Chou: Steel Res. Int., 2015, vol. 86, pp. 391–99.

Q. Wen, F. Shen, H. Zheng, J. Yu, X. Jiang, and Q. Gao: ISIJ Int., 2018, vol. 58, pp. 792–98.

H.-Y. Wang, Y. Hou, G.-H. Zhang, and K.-C. Chou: ISIJ Int., 2020, vol. 60, pp. 636–39.

T. Tanaka, T. Ogiso, M. Ueda, and J. Lee: ISIJ Int., 2010, vol. 50, pp. 1071–77.

J.H. Park: Steel Res. Int., 2013, vol. 84, pp. 664–69.

S. Kobayashi: ISIJ Int., 1999, vol. 39, pp. 664–70.

H.-S. Kim, H.-G. Lee, and K.-S. Oh: ISIJ Int., 2002, vol. 42, pp. 1404–11.

H.L. Yang, J.S. Ye, X.L. Wu, Y.S. Peng, Y. Fang, and X.B. Zhao: ISIJ Int., 2016, vol. 56, pp. 108–15.

D.-H. Woo, K. Youn-Bae, and H.-G. Lee: Metall. Mater. Trans. B, 2002, vol. 33B, p. 915.

D. Roy, P.C. Pistorius, and R.J. Fruehan: Metall. Mater. Trans. B, 2013, vol. 44B, pp. 1095–1104.

D. Roy, P.C. Pistorius, and R.J. Fruehan: Metall. Mater. Trans. B, 2013, vol. 44B, pp. 1086–94.

J. Xu, F. Huang, X. Wang, and C. Jing: Steel Res. Int., 2016, vol. 87, pp. 1694–1701.

X. Jianfei, H. Fuxiang, W. Xinhua, and J. Cailiang: Iron Steel, 2016, vol. 52, pp. 45–51.

K. Takahashi, K. Utagawa, H. Shibata, S.-Y. Kitamura, N. Kikuchi, and Y. Kishimoto: ISIJ Int., 2012, vol. 52, pp. 10–17.

L. Fei, Z. Changdong, and M. Jianehao: Shanghai Met., 2014, vol. 36, pp. 20–26.

S. Lee and D.J. Min: Met. Mater. Int., 2019, vol. 25, pp. 248–56.

J. Zhao, H. Zhu, L. Wang, M. Song, J. Li, and Z. Xue: Ironmak. Steelmak., 2022, vol. 49, pp. 302–310.

L. Cheng, L. Zhang, Y. Ren, and J. Zhang: J. Alloys Compd., 2020, vol. 845, pp. 2–10.

L. Cheng, Y. Ren, T. Liu, and L. Zhang: Steel Res. Int., 2022, vol. 93, p. 2100703.

L. Zhang, L. Cheng, Y. Ren, and J. Zhang: Ceram. Int., 2020, vol. 46, pp. 15674–85.

J. Lee and K. Morita: ISIJ Int., 2004, vol. 44, pp. 235–42.

T. Yoshikawa, K. Motosugi, T. Tanaka, and M. Ueda: Tetsu-to-Hagané, 2011, vol. 97, pp. 361–68.

P. Shen, L. Zhang, J. Fu, H. Zhou, Y. Wang, and L. Cheng: Ceram. Int., 2019, vol. 45, pp. 11287–95.

M. Humenik Jr. and W.D. Kingery: J. Am. Ceram. Soc., 1954, vol. 37, pp. 18–23.

E.P. Heikkinen, T. Kokkonen, R. Mattila, and T. Fabritius: Steel Res. Int., 2010, vol. 81, pp. 1070–77.

S. Ozawa, K. Morohoshi, and T. Hibiya: ISIJ Int., 2014, vol. 54, pp. 2097–2103.

R. Brooks and P. Quested: J. Mater. Sci., 2005, vol. 40, pp. 2233–38.

Y. Su, Z. Li, and K.C. Mills: J. Mater. Sci., 2005, vol. 40, pp. 2201–05.

K. Nakashima and K. Mori: ISIJ Int., 1992, vol. 32, pp. 11–18.

M. Hino and K. Ito: Thermodynamic Data for Steelmaking, Tohoku University Press, Sendai, 2009.

Acknowledgments

The authors are grateful for support from the National Key R&D Program (No. 2023YFB3709900), the National Natural Science Foundation China (Grant No. U22A20171), the Hebei Natural Science Foundation (Grant No. E2021203062), and the High Steel Center (HSC) at Yanshan University, Hebei Innovation Center of the Development and Application of High Quality Steel Materials, Hebei International Research Center of Advanced and Intelligent Manufacturing of High Quality Steel Materials.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Huang, C., Ma, T., Ren, Q. et al. Wettability and Interfacial Phenomena Between Silicon and Sulfur-Bearing Steels and Solid CaO Substrates. Metall Mater Trans B 55, 1830–1842 (2024). https://doi.org/10.1007/s11663-024-03069-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-024-03069-3