Abstract

A decision support system was developed using supervised machine learning (ML) approach for optimization of calcium (Ca) additions by continuously monitoring the physical state of non-metallic inclusions (NMIs) inside low-alloyed liquid steels. In this work, two instances were considered to design the base algorithm for the proposed supervisory system: (1) Clogging of submerged entry nozzle (SEN) during continuous casting of steels due to accumulation of solid oxide non-metallic inclusions (NMIs) and (2) Ca treatment during secondary steelmaking for modification of oxide NMIs from solid to liquid state to avoid SEN clogging. At first, experimental investigations were carried out on liquid steel samples from three low-alloyed Ca-treated steel grades from the same steel family to evaluate the characteristics of solid oxide NMIs that cause SEN clogging. In the next step, data-driven models were developed using an in-house ML algorithm trained primarily with process data for calculating the value of the newly proposed dummy parameter ‘Clog.’ These models, after testing, were architected to develop a supervisory system based on experimental investigations and data-driven models. The objective of this proposed supervisory system was to predict the optimum quantity of Ca needed for successful modification of NMIs from solid to liquid state to avoid SEN clogging based on the forecasted ‘Clog’ value. Finally, industrial data from ~ 3000 heats were tested to verify the results obtained from the developed supervisory system. The results confirmed that this novel supervisory system could predict the optimum class of Ca for all studied steel grades with 95 to 98 pct accuracy. The integration of this online supervisory system in steel production is expected to minimize operators’ corrective actions in achieving realistic control of Ca additions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Online process monitoring concerning steelmaking is challenging due to various physical, mechanical, and chemical interactions of process parameters and stochastic events. Complexity in occurrence of these events limits conventional hardware systems for monitoring the appropriate operating conditions. The increasing global demand[1] for clean steel created a need to develop new predictive process monitoring and control methods. Steelmakers seek accurate monitoring of various operations since even the slightest variation during the production causes costly and time-consuming post-processing or an increase in material scrappage. The primary challenge for developing a predictive monitoring tool is to analyze the process data collected during steelmaking. As the need for realistic process monitoring at various stages of steelmaking is constantly on demand, designing new statistical algorithms utilizing collected process data for the prediction of stochastic events caught the attention of researchers.[2,3,4] Clogging of the submerged entry nozzle (SEN) during continuous casting of steel is one such stochastic event that needs to be carefully monitored from a steel castability perspective.[5] Severe SEN clogging leads to disturbance in the casting of steel[6,7,8,9] and significant damage to steel cleanliness.[10,11,12] To reduce problems associated with SEN clogging, steelmakers use calcium (Ca) in the form of powder or wire to modify the detrimental non-metallic inclusions (NMIs) and to desulfurize the steel.[11,13] One of the major goals of Ca additions is to transform solid-state NMIs into liquid-state NMIs.[12] It has been found in the previous study that the addition of Ca also has a positive influence on the shape and size of NMIs.[14] Using thermodynamic calculations, one can understand the formation of various NMIs when liquid steel reacts with steel, slag, and refractory at a particular temperature. In recent years, there has been enormous research work in designing thermodynamic and kinetic models to understand the formation and evolution of NMIs in accordance with steelmaking conditions.[15,16] Researchers used the most recent coupled reaction EERZ model to check changes in NMIs composition with respect to the different processing times.[15,17] ThermoCalc has investigated the usage of EERZ models in simulating the ladle treatment and vacuum-degassing process to evaluate the composition of NMIs at different temperatures and oxygen contents.[18] Although these models were beneficial for process design, they had some computational limitations for online process monitoring because of very long simulation times. Inclusion engineering and control are paramount for improved castability and cleanliness.[9,19] SEN clogging problems caused by solid NMIs containing spinel (MgO·Al2O3) and alumina (Al2O3) clusters have been reported in the past.[20,21] Therefore, the precise control of the soluble aluminum (Al) and magnesium (Mg) in the liquid melt is predominant in inhibiting spinel formation and indirectly SEN clogging later during casting. Ca additions can help transform solid spinel NMIs into liquid complex NMIs if the soluble Ca content in the liquid steel reaches the optimum level.[22] Although Ca has good modification ability, improper additions will bring adverse effects. For example, insufficient Ca addition leads to formation of solid calcium aluminates (CaO·Al2O3), which are detrimental to castability, whereas if added in excessive amounts, redundant Ca will react directly with sulfur (S) in steels to form high melting calcium-sulfide (CaS) NMIs.[23] These NMIs can also degrade the castability of steel. Therefore, estimating the optimum Ca required through Ca addition is vital to avoid unwanted processing problems in later stages. Nevertheless, optimizing Ca addition only based on soluble Ca contents inside the steel is not ideal from metallurgical aspects. It is necessary to investigate other parameters influencing the Ca addition apart from soluble Ca contents inside the steel. For example, the characteristics like size, shape, and state of NMIs found in steel must be important when deciding the Ca additions.[24,25] It is, therefore, necessary to analyze the physical state of NMIs at different stages of steelmaking in real time to evaluate the optimum quantity of Ca additions needed for manufacturing specific steels. The conventional characterization techniques of steel samples do not give real-time information on the NMIs state, morphology, and composition.[26,27,28] However, due to tightened steel cleanliness requirements (particularly for high-quality steel grades), it has also become necessary to obtain faster estimations of NMIs characteristics in liquid steel to control the process during secondary steelmaking and continuous casting. Optical Emission Spectroscopy combined with Pulse Distribution Analysis (OES-PDA) is an analytical technique for rapid detection of steel and NMIs composition, developed in the past decades.[13] Many steelmaking companies used the OES-PDA method for rapid elemental analysis (in minutes) of the steel samples collected from producing steel grades.[13,29]

Previous research primarily focused on how calcium (Ca) additions modify non-metallic inclusions (NMIs) to prevent Submerged Entry Nozzle (SEN) clogging. However, these studies often underestimate the real-time changes in the physical states of NMIs during processing. Therefore, this study introduces self-adjusting machine learning (ML) models as a new solution. These models optimize calcium (Ca) addition during processing, considering the evolving chemistry of steel and NMIs. Here, self-adjusting means that the input parameters associated with the trained ML model can be automatically adjusted as the steelmaking advances from secondary metallurgy to continuous casting. In steelmaking terms, manufacturing one batch of steel is termed ‘Heat’. Every heat has a unique identity, so it is crucial to develop models that can self-adjust to predict precise output, even when anonymous data are introduced from new heats. This way, faster monitoring of NMIs characteristics is possible, and rapid decisions (within seconds) about process control, including estimation of precise Ca addition, can be made. The research contribution in this study can be summarized as follows: at first, laboratory experiments were performed to investigate the characteristics of the NMIs in steel samples and to identify the judgment criteria for avoiding SEN clogging based on the physical state of NMIs. A supervised ML system was developed in the second step to predict an optimum amount of Ca additions to modify solid oxide NMIs based on judgment parameters. When tested with real-time process data, the developed supervisory system achieved prediction accuracy within the range of ~ 95 to 98 pct. In this case, the newly introduced ‘Clog’ parameter helped to obtain more accurate predictions when combined with other input parameters such as steel and NMIs chemistry.

Background

Machine learning (ML) is a subset of artificial intelligence and has become popular in solving real-world problems.[30] Since steelmaking involves too many complex events, various process parameters, and metallurgical requirements, use of ML approach is beneficial for optimization and pattern recognisation during production. After examining the literature associated with ‘steelmaking’ and ‘machine learning,’ it was found that the number of articles reported concerning these two keywords increased significantly in recent years. Figure 1 shows the trend between the number of articles reported in relation to keywords ‘machine learning’ and ‘steelmaking’ in the recent decade.[31]

The graph showcases the trend between the number of articles concerning the keywords ‘steelmaking’ and ‘machine learning’ in the recent decade.[31] Arrow depicts the probable increasing trend of articles to be published in the remaining 2023

In the past, supervised learning, unsupervised learning, and reinforcement learning were used by researchers to solve problems associated with steelmaking.[4] Many researchers used conventional regression methods to predict a numerical value of a target variable with given input variables. The pre-processing of process data, which includes cleaning, normalizing, transforming, imputing missing values, integrating, identifying noise,[3,32] and feature extraction,[33] is critical in ML model development. An important aspect of feature extraction is selecting relevant parameters and discarding irrelevant ones. Following this, the data are divided into training and testing sets. The training set is utilized to fit parameters and identify the best ML algorithm, while the testing set is employed to evaluate the models’ performance. Following this, data are split into training and testing sets; the training set is used to fit parameters and hypothesize the best ML algorithm, while the testing set evaluates the models’ performance. Cross-validation, involving further splitting of the training data into subsets, is employed for algorithm optimization.[3] In online process monitoring, ‘classification-based’ and ‘regression-based’ approaches are commonly used. Performance metrics such as accuracy, precision, recall, F1 score, ROC curves, and MCC are evaluated using a confusion matrix. Accuracy measures the fraction of correctly classified instances, shown in Eq. [1]:

Precision measures the ratio of correctly predicted positive instances among all positive predictions, shown in Eq. [2]:

Recall measures the ratio of correctly predicted positive instances among all positive instances, shown in Eq. [3]:

F1 score measures the harmonic mean of precision and recall, shown in Eq. [4]:

If the actual label of a specific instance is positive and a model correctly predicts the label, it is referred as true positive (TP), and if not, it is considered as false negative (FN). In other scenario with a negative label, one considered the model output as false positive (FP) in case of an incorrect prediction, and a true negative (TN) in case of correct prediction. In the present study, similar evaluation metrics were used for checking the efficiency of predicted results.

For regression-based ML, the Mean Absolute Error (MAE), the Mean-Squared Error (MSE), and the Root-Mean-Square Error (RMSE) are generally used as evaluation metrics. The interesting details were highlighted in the report published.[34] MAE is the mean absolute difference between the predicted values and the actual values in a dataset. The lower the MAE, the better a model fits a dataset. MAE can be calculated as shown in Eq. [5] where \({e}_{t}\) denotes absolute error. It is a difference between true and predicted measure.

MSE is the average sum of the squared difference between predicted and actual values. It can be calculated as shown in Eq. [6]:

RMSE is the square root of the MSE value. It can be calculated as shown in Eq. [7]:

Recently, researchers also used various ensemble-based regression techniques such as Gradient-Boosting, Random Forest, Neural Network, and XG Boost to predict a real value which is a performance measure of the casting process, such as the castability index for continuous casting.[35] The castability index was based on an after-process analysis of the data collected from the continuous casting machine. This approach has the disadvantage of indirect measurements but the advantage that one could predict classical cleanliness data, which is much more difficult to obtain experimentally. In all reported ML models, the challenge of incorporating imbalanced datasets emerged. The number of normal, non-defective operations was many times higher than the number of defective instances such as clogging. In terms of ML, this is also referred to as a skewed or biased dataset.[4] To justify the information obtained from biased datasets, one needs to understand that the direct prediction of defects in steelmaking is a very challenging task, which can also be complicated by various anomalies seen at the time of production. Therefore, base algorithms behind ML models should be chosen carefully so that the predicted output can be justifiable. To develop a supervised ML model that meets industrial requirements, researchers also used Artificial Neural Networks (ANN).[36] Vannucci et al. used regression models instead of classification of clogging events to predict the rate of nozzle obstructed area.[37] Most recently, algorithms based on casual graphical models have been reported for process monitoring in continuous casting.[38] The concept of automated machine learning (Auto-ML) was also used, which comprised automating the tasks involved in developing ML pipelines for the application to real-world scenarios.[39] A more detailed review of different use cases associated with applied machine learning in continuous casting was published recently.[4] In all the reported strategies, historical data were trained and evaluated by developing various ML algorithms. However, the actual deployment of these models in production was given little to less attention, limiting the applicability and further research. In the era of realistic digitalization, it is high time for steelmakers to use deployable ML systems for process monitoring and control. This study aimed to achieve this goal by designing a novel decision support system using supervised ML. The methodology behind the development of the proposed supervisory system is highlighted in the next section.

Methods

Data Analysis and Industrial-Scale Sampling

A dataset from the production of three industrial Ca-treated low-alloyed steel grades, prone to clogging problems, was selected for this research. The main compositions of these industrial low-alloyed steel grades are given in Table I. For confidential reasons, only the main elements were highlighted. Steel samples were collected from four stages, S1 from the ladle furnace before vacuum degassing; S2 after vacuum degassing and before calcium wire addition; S3 from the ladle furnace after calcium wire addition; and S4 from the tundish during continuous casting. Afterward, each sample was investigated using the electrolytic extraction (EE) and OES-PDA method. A schematic of the industrial steelmaking process and sampling is given in Figure 2.

Experimental Investigation

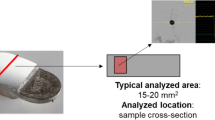

Steel samples from S1, S2, S3, and S4 were taken in a standard lollipop sampler to investigate the evolution of NMIs in various process stages of steelmaking. Three-dimensional (3D) investigations of NMIs on film filters after electrolytic extraction (EE) for all samples were carried out in a 10 pct AA (10 pct acetylacetone—1 pct tetramethyl-ammonium chloride-methanol) electrolyte to evaluate the morphology, size, and composition of NMIs. During electrolytic extraction, the steel matrix was dissolved, and the undissolved NMIs were extracted and collected on a film filter after the filtration of electrolyte. A detailed description of the EE method and main parameters were reported in a previous study.[40] The NMIs collected on the film filters were examined using a Scanning Electron Microscopy (SEM) equipped with Energy-Dispersive Spectroscopy (EDS). As the OES-PDA technique is comparatively rapid and beneficial for online analysis, in-house OES-PDA equipment available at the voestalpine steelplant in Linz, Austria was used for the investigation of NMI’s composition. A high-energetic discharge of electric sparks (1500 to 2000 spectra number) with a frequency of 100 to 800 Hz was used to collide on the steel sample surface. On the collision of the spark, the light of different wavelengths was emitted specific for each element. The light intensity for each wavelength was measured with respective photomultipliers. In the next step, the total mass fraction of each element in the ablated material was obtained based on a specific calibration function. A schematic illustration of the OES-PDA setup is shown in Figure 3. In the next step, the OES-PDA dataset was developed by carefully analyzing the bulk steel chemistry from the samples S1, S2, S3, and S4 for each studied steel grade. In addition, contents of Al, Mg, Ca, oxygen (O), and S in mass pct from typical NMIs prone to SEN clogging were analyzed through PDA spectra and added to the dataset mentioned above.

Machine Learning Model Development

In the proposed work, supervised machine learning strategy was employed to develop a decision support system for predicting optimal Ca levels in steelmaking. This approach was chosen to utilize labeled data for training the model to accurately predict outcomes based on the state of NMIs. The investigation began with the generation of dataframes combining experimental and steelmaking process data, analyzed using Python libraries like Numpy, Pandas, Scikit-learn, Matplotlib, Seaborn, and Shap on a 64-bit Windows system with an Intel (R) Core (TM) i7-8665U CPU. The dataframes were divided into training, validation, and testing sets (see Electronic Supplementary Figure S1), with cross-validation applied on the training and validation sets to minimize overfitting. A K-Fold cross-validation with K = 5 was selected for a balance between computational efficiency and reliable performance estimation.

The strategy behind designing a data-driven algorithm was to predict changes in the steel and NMIs chemistry by monitoring the process parameter ‘Clog’ along the steelmaking process stages and accordingly optimize the quantity of Ca additions required for modifying the state of NMIs. The base algorithm behind this strategy is shown in Figure 4, and the modeling architecture is highlighted in Figure 5. Four submodels were architected to take the input data with respect to sampling stages S1, S2, S3, and S4. The function of each submodel was designed to feed with the historical conditions giving importance to previously predicted information. This made it possible to identify how the ‘Clog’ parameter responds to expected and unexpected user actions (Ca addition), its response time, usability, and reliability issues. Each submodel shown in the model architecture was designed to predict the characteristic state of NMIs at respective stages of steelmaking by considering the input from the last recorded OES-PDA data. All four submodels were trained and optimized by using Python-compatible scikit-learn functions for the regression-based and classification-based tasks.

Regression approach

The primary input of each submodel involves information regarding the bulk (total) steel composition obtained through OES consisting details of elements Al, Ca, Mg, O, and S. In this study, Gradient-Boosting Regression (GBR) was utilized to predict the soluble (present inside steel) and insoluble (present inside NMIs) content of elements. GBR was preferred since it has capability of learning complex and hidden patterns in the input data. In general, it is sensitive to outliers compared to other regression functions, but it can iteratively build a series of weak decision trees on the residuals from previous trees, ultimately forming a strong predictor. The main advantage of using GBR was that it could be customized with various loss functions and weak learners, allowing it to be self-adjusted and tailored to any specific deviation in the data. The GBR was used, therefore, to train the decision support system ensuring that at each processing stage, it helped calculating and monitoring so-called ‘Clog’ parameter. The parameter value as shown in Eq. [8] was based on the ratio of total calcium (calcium content present inside steel and NMIs) and insoluble aluminum (aluminum content present only inside the NMIs). The significance of this parameter in detecting the state of NMIs was examined from experimental investigations carried out in this work.

GBR was later optimized by tuning several key hyperparameters, including the learning rate, number of estimators, maximum depth, subsample, minimum samples required to split an internal node, and minimum samples required at a leaf node. A grid search approach with cross-validation was employed to identify the best combination of hyperparameters. Cross-validation helped in this process to ensure that the model’s performance was also assessed on different subsets of the data, providing accurate, reliable and unbiased results. At first, all four submodels were trained on dataset comprising process data of ~ 3000 heats of each studied steel grade. As mentioned earlier ‘5-fold’ cross-validation was applied on this dataset to avoid underfitting as well as overfitting problems (see Supplementary Figure S2). The test dataset containing ~ 500 heats of each steel grade was examined further to evaluate the performance of the trained submodels. In development of regression-based approach, single trainer was preferred over fusion of multiple trainers making it simple to develop, implement for real-world predictions and less complex in interpreting the results. Apart from GBR, ten other ML algorithms were also analyzed for each submodel (see Electronic Supplementary Tables S1 through S5).

Classification approach

The datasets comprising steel and NMIs chemistry and the predicted ‘Clog’ parameter were sorted manually using four labels based on industrial practice. In this case, the label ‘Class 1’ denoted Ca additions ranging between 0.00 and 0.10 kg/ton of steel; ‘Class 2’ denoted Ca additions ranging between 0.10 and 0.20 kg/ton of steel; ‘Class 3’ denoted Ca additions ranging between 0.20 and 0.30 kg/ton of steel, and ‘Class 4’ denoted with Ca additions ranging between 0.30 and 0.40 kg/ton of steel. Accordingly, a multilabel classification tasks was set for the decision support system. In this work, the ensemble technique comprising Random Forest (RF) algorithm[41] was the primary choice to predict these four classes by examining the input process data. In general, RF algorithm combines the predictions of multiple decision trees, making the classification task less prone to overfitting problem. One of the reasons of selecting RF as a base algorithm was to identify the most important input features that had the most significant impact on the Ca additions for each predicted ‘Class’. A single trainer RF was preferred over multiple-fused trainer, since there could be high chance of overfitting. During real-time monitoring tasks, single trainer RF could be quick to train, and computationally robust to predict the outcomes than compared to fusion of multiple weighted trainers.[3] However, prior to selection of RF as a base algorithm, several other boosting and ensemble algorithms were examined such as Hist-Gradient-Boosting, Ada-Boost, Decision-Tree, Gradient-Boosting, etc. (see Electronic Supplementary Table S1). The grid search method was applied for each submodel to identify the best hyperparameter for the selected base RF function. This hyperparameter optimization was considered to tune the hyperparameters such as the ‘number of trees,’ ‘maximum features,’ the ‘maximum depth of the trees,’ etc. After optimization, the RF classifier with the most accurate, and quick-to-train characteristics were selected for evaluating the unseen data of ~ 500 heats from test dataset. The performance of optimized RF applied in each submodel was reported based on evaluation metrics accuracy, precision, recall, and F1 score, respectively (see Electronic Supplementary Tables S6 through S9).

Results

Experimental Based

The morphology of typical NMIs found in the analyzed steel grades using EE-SEM-EDS method are highlighted in Figures 6(a) through (d). Mainly pure aluminum oxide NMIs, aluminum oxide clusters, spinels made of aluminum-magnesium oxides, and complex oxide NMIs containing aluminum calcium magnesium oxides with calcium sulfide were found. The NMIs found in samples S1 and S2 were mainly clusters of solid aluminum oxides, whereas those found in S3 and S4 were globular liquid and complex oxides. It was observed that Ca addition effectively modified the morphology of the NMIs. However, regarding the transformation of the state from solid NMIs to liquid NMIs, it was no clear justification, as in EDS investigation, compositions only from the outer layers of NMIs were determined. A favorable region of the NMIs state or ‘liquid window’ was superimposed on the graph showcasing the ‘clogging’ tendency of SEN, refer Figure 7. Further, three zones were obtained inside the same graph based on the domain metallurgical knowledge. It was found that the NMIs observed in Zone 1 and Zone 3 were prone to SEN clogging, whereas those in Zone 2 comprised liquid oxides, which favors good castability and negligible SEN clogging. When using OES-PDA analysis, soluble elements (present only inside steel), insoluble elements (present only in NMIs), and the total elemental concentration (present in both steel and NMIs) can be observed. Figures 8(a) through (f) highlights the contents (in mass pct) of Al and Ca (prone for nozzle clogging) found when using the OES-PDA method. In addition, the concentration (in mass pct) of other single elements like Al, Ca, Mg, and S and O were also found in complex NMIs observed in the subsequent sampling stages.

Machine Learning Model-Based

In this subsection, the results obtained using the regression approach and classification approach are highlighted. Several evaluation metrics were used to estimate the goodness of each prediction. It was found that all submodels were effectively trained using base GBR without overfitting. Table II highlights brief overview of performance of GBR and optimized GBR regressor for all submodels based on MAE, MSE, RMSE, and R2 (see electronic supplementary Figures S3 through S6). The optimized GBR demonstrated improved performance compared to baseline GBR. Table III highlights the optimal values of best hyperparameters to optimize the base GBR. The optimal hyperparameter values identified through grid search and cross-validation were learning rate of 0.01, number of estimators of 300, maximum depth of 5, minimum samples split of 3, and minimum samples leaf of 2. These values allowed base GBR model to capture complex patterns in the data while maintaining overall generalizability.

Similarly, MAE and MSE values highlighted the average magnitude of the errors in predictions for testing dataset. Using regression approach ‘Clog’ parameter was predicted and monitored in real-time at different stages as presented in Figure 9(a). The results of the predicted response vs true response for the ‘Clog’ parameter value are highlighted in Figure 9(b).

(a) ‘Clog’ parameter value was monitored at the process stages S1, S2, S3, and S4 using the proposed supervisory system for 100 random ‘heats’ while continuously checking the total amount of Ca inside the steel for the occurrence of liquid NMIs. (b) Predicted response vs True response plot from regression approach

Table IV highlights the optimal values of obtained hyperparameters to optimize the base RF. The optimized RF model was found to perform best with a forest size of 200 trees, a maximum of three features considered for each split, and a maximum depth of ten. These hyperparameters were found to optimize the balance between model complexity and performance, and to prevent overfitting. The selection of these hyperparameters helped ensure that the optimized RF model achieved high accuracy and stability on the unseen heats from test dataset.

Random heats of grade 1, grade 2, and grade 3 were selected for the evaluation of the overall response of the model. The classes of Ca addition were predicted based on the ‘Clog’ value observed at various zones and steel chemistry obtained from analyzed heats. Table V summarizes the different evaluation metrics used to verify the classification approach. Accordingly, accuracy, precision, recall, and F1 score were estimated for test dataset. Receiver Operating Characteristic (ROC) curves were also found for better interpretation of predicted response for each predicted ‘Class’ (see Electronic Supplementary Figure S7).

Discussions

The NMIs found in the steel samples before Ca addition were oxides of aluminum and magnesium [refer to Figures 6(a) through (c)]. As the steel grades were Al killed, it was obvious that aluminum oxide NMIs were found before Ca addition as a consequence of the deoxidation reactions. This was also justified as per the previously reported studies.[20,42] Magnesium oxides NMIs were probably formed due to reactions of steel with magnesium from ladle refractory materials[43] and as the secondary steelmaking process continued, aluminum oxide NMIs were agglomerated to form irregularly shaped bigger-size clusters [refer to Figure 6(a)]. According to previously reported work, these clusters of aluminum oxides were most prone to SEN clogging.[44,45] These harmful NMIs are subsequently transformed into different sizes, shapes, and physical states depending on the quantity of Ca addition. For example, when Ca was added to the steel, aluminum oxide NMIs were transformed into globular shape complex oxides [refer to Figure 6(d)].[40] These NMIs were comparatively smaller and less prone to form clusters causing SEN clogging. Previous work also reported the presence of micro-size NMIs in Ca-treated steel grades.[11,45,46,47] Similar micro-size NMIs in the range of 1 to 4 µm were found in the samples analyzed by EE-SEM-EDS. As previously reported,[25,48,49,50] small-size NMIs should be transformed from solid state into liquid state after Ca addition. However, as mentioned earlier in the result section, there was no clear indication of the physical state of NMIs, before and after Ca treatment, just by analyzing EE-SEM-EDS data. This is because EE-SEM-EDS data provided only elemental chemistry and not phase-related information.[51] Hence, it was necessary to append information from thermodynamic phase diagrams of CaO and Al2O3 along with EE-SEM-EDS to find the clear physical state of NMIs. Therefore, the concept of ‘liquid window’ was superimposed on the gathered experimental results for a better understanding of the facts related to the transformation of NMIs with respect to Ca addition and processing factors such as temperature. In a recent report, plant trials and thermodynamic modeling work were reported to better understand this transformation mechanism for different amounts of Ca addition in relation to the ‘liquid window’.[52] In this study, a similar but more realistic approach was investigated to determine the optimum operation window for NMIs transformation as per Ca addition to the steel. A combination of ‘liquid window’ concept together with EE-SEM-EDS analysis showed the probable physical state of NMIs. As observed after Ca addition, most of the NMIs in the heats from grade 1 were transformed to liquid state, whereas in grade 3, most of the NMIs were not transformed. The results for grade 2 compared to grade 1 and grade 3 were largely scattered (refer to Figure 7). This observation led to the discussion regarding the need of different quantities of Ca additions for different steel grades for NMIs transformation. This finding also showed that heats from grade 1 were least susceptible to SEN clogging, as most of the NMIs were already transformed to complex globular liquid oxides, whereas SEN clogging events could occur more often in heats of grade 3. The relation between amount of Ca addition and steel grades should be investigated further to get a clearer understanding of this transformation mechanism.

It was challenging to predict SEN clogging events for heats of grade 2, as NMIs data were not distributed evenly and had variations along the plot (refer to Figure 7). The soluble and insoluble content of calcium and aluminum in heats of grade 2 slightly differ compared to soluble and insoluble contents in the heats from grade 1 and grade 3 [refer to Figures 8(a) through (f)]. Here soluble referred as composition inside steel and insoluble referred as composition inside NMIs. Deoxidation reactions inside steel at S1 and S2 might increase the total aluminum content in all investigated steel grades [refer to (Figures 8(a), (c), (e)]. However, there was no significant increase in the soluble aluminum content inside all steel grades at S3. After Ca addition, both the soluble and the insoluble content of aluminum decreased [refer to (Figures 8(a), (c), (e)]. On the other hand, for all the steel grades, the insoluble calcium content increased after sampling in stage S3. This justifies the presence of calcium in the newly formed NMIs after Ca addition [refer to (Figures 8(b), (d), (f)]. Interestingly for grade 2, this increase in insoluble calcium content was initiated already after stage S2. This means that just before Ca addition to the grade 2 heats, reactions inside the steel and NMIs might triggered the increase of calcium content in the NMIs. This could be due to steel-slag reactions, steel-refractory reactions, or any other effect of added alloying elements to liquid steel. Since this tendency was only observed in grade 2, it is also important to discuss whether the slag composition should be considered, while optimizing the calcium content apart from the steel composition. In recent reported studies, researchers already considered steel-slag-refractory reactions while detecting NMIs phases.[15,17] One of the major findings from OES-PDA was that irrespective of the grade and heat, there was a clear indication that due to Ca addition, the composition of aluminum and calcium inside the NMIs changed significantly. However, there is no clear rule stating to what quantity the Ca addition changed this insoluble content. This means that dynamic and closely controlled Ca addition would be the key to the successful transformation of most of the NMIs. At present, for steelmaking, there is no standard rule for calculating the quantity of Ca addition based on the changes in the content of calcium and aluminum inside NMIs. The developed model in this work can contribute to a closer prediction of Ca addition to the steel bath in a more dynamic way.

Before building the ML model, the data were pre-processed to ensure removal of any unwanted outliers which can significantly affect model predictions. The quality of the input data was improved, allowing the model to focus on learning meaningful relationships from the data rather than being influenced by noise or outliers. This attention to data quality ultimately contributed to the model’s robustness and its ability to provide accurate predictions for the given task. The MAE, MSE, and RMSE metrics values were comparatively similar for all studied steel grades for all submodels (refer to Table II) when tested on test dataset. This indicates the hyperparameters of the selected ML algorithm in all submodels had top-tier predictions when tested on new unseen data. While this could work here, it is still suggested not to use these developed submodels blindly without tuning them for new heats. Since the used submodels were trained on specific data frames, it could be possible that the trained submodels might not achieve exact MAE, MSE, and RMSE values as reported for other datasets. Further, one could also see that different submodels could behave differently. For example, MSE and RMSE values for submodel 2 and submodel 4 were almost similar compared to submodel 1 and submodel 3. This could be due to several reasons associated with the method of splitting data for training and validation, the dataset used for tuning the hyperparameters, or the associated patterns in the datasets. The authors believe that the evaluation performance of the training data should not be considered for deployment perspectives as every ‘heat’ is unique and could lead to distinct patterns. Most relevant here is to promote the importance of a data-centric approach rather than a model-centric one as reported in the previous study.[3]

In Figure 9(a) the gray region highlights the optimum ‘Clog’ value, suggesting the complete transformation of NMIs from solid to liquid, where the primary purpose, in this case, was to check the condition of NMIs along the steelmaking route. The ‘Clog’ value along the secondary steelmaking changes subsequently. Before Ca addition, at S1 and S2 stages almost every heat had a ‘Clog’ value in the range of 0 to 2. NMIs found at these stages were mainly in solid-state, which is also scientifically reasonable due to the occurrence of aluminum oxide NMIs. After Ca addition, in some heats the ‘Clog’ value significantly increases at S3. However, a small deviation was observed in the ‘Clog’ value at S4 stage when the steel melt was inside the tundish. As seen in Figure 9(b) the model-predicted response of the ‘Clog’ value prediction was almost the same as the true response recorded from the industrial sampling. However, for some heats the model showed some deviation in the prediction of the ‘Clog’ value. This might be due to data variations or errors associated with the training of the submodels. True response means that the ‘Clog’ value calculated is based on the total calcium and the insoluble aluminum content, where the ‘Clog’ value could be calculated directly from OES-PDA data manually. While the ‘Clog’ value could be manually calculated without involving ML, the challenge arises from an online process control perspective. Calculating the real-time ‘Clog’ value for immediate use in steelmaking operations is complicated, primarily due to the time-consuming nature of PDA analysis. It takes several minutes to provide NMIs composition. During this time, state transformations may occur in the NMIs in liquid steel, influencing the requirements for Ca additions. To address this challenge and ensure effective online process control, the ‘Clog’ value was rapidly predicted using GBR. This prediction incorporated direct inputs from steel chemistry obtained from OES and historical ‘Clog’ values, allowing for timely assessment of NMIs’ presence. To the best of the authors’ knowledge, such a concept has not existed until now. Using this proposed methodology, steelplant operators would be able to predict near-to-real-time conditions associated with NMIs transformations.

The ML model-based results showed that the selection of GBR algorithm for regression was most significant since the patterns observed from training data were utilized most accurately to make predictions later, on new unseen testing datasets. The evaluation of the classification approach in which the RF algorithm was used showed a similar tendency for grade 1, grade 2 and grade 3 in terms of accuracy, precision, recall, and F1 score (refer to Table III). In predicting the optimum class a random heat accuracy of 85 to 95 pct, a precision of 83 to 98 pct, a recall of 83 to 98 pct and a F1 score of 0.76 to 0.99 was obtained through the developed submodels. The results showed, that ‘Class 1’ and ‘Class 2’ were predicted more accurately on training, validation and testing datasets for all studied steel grades. However, slight deviations were observed in the precision values of ‘Class 3’ for both training, validation and testing datasets from steel grade 3. One of the reason was the variance in the training data for the heats from steel grade 3. This could be improved in the future by using a larger dataset for training of the model in relation to steel grade 3.

The statistical correlation of the process data obtained using OES-PDA showed a significant correlation between the elemental compositions found in bulk steel compositions and those found in NMIs causing SEN clogging. Nomenclature was described in Appendix (refer to Table AI). It was found that the correlation between the elemental steel composition and the NMIs drastically change after Ca addition. The correlation matrix (refer to Figure 10) gave a relatable idea for understanding the best features selection for predicting the ‘Clog’ value using the regression approach. For example, when comparing the data before and after Ca addition, the ‘Clog’ parameter strongly correlated with the insoluble calcium and total aluminum content inside the steel. In contrast, its most vital negative dependence was on the total magnesium and oxygen content. The correlation between elemental composition in different NMIs and the ‘Clog’ value helped to understand how to predict the transformation of NMIs chemistry by monitoring only the ‘Clog’ value. For example, before Ca addition, it was challenging to predict regarding parameters CA_ACM and AL_ACM (which highlighted the calcium and aluminum contents inside [(Al2O3–CaO–MgO) + CaS] NMIs respectively), based on the ‘Clog’ value, since the correlation coefficient was negative and significantly lesser than one. However, this changed after Ca addition as the correlation coefficient became positive and comparatively greater. Such small, but significant correlation were seen for other NMI compositions as well.

Correlation matrix showcasing the relationship between elemental compositions observed in steel and NMIs obtained through OES-PDA analysis before and after Ca addition with respect to the calculated ‘Clog’ parameter. Here value ‘1’ indicates the maximum positive correlation marked in red, and ‘− 1’ indicates the maximum negative correlation marked in blue

The correlated data from EE and OES-PDA regarding ‘liquid window’ gave almost similar results for all studied steel grades. This investigation was needed since OES-PDA data have been used as main input parameters for model development. The main motivation here was to check the changes in the NMIs chemistry previously observed through EE-SEM-EDS with respect to the changes in composition of the steel and NMIs observed from OES-PDA analysis. Similar studies were reported in the past. Where researchers checked the connection between EE experiments and OES-PDA.[48,53] As already mentioned in the result section, the ‘liquid window’ was designated as the safe operating window for successful processing conditions during Ca treatment, where this ‘liquid window’ also depends on the temperature.[52] The window expanded significantly as the temperature increased from 1500 °C to 1600 °C (refer to Figure 11). In the current study, a static ‘liquid window’ at 1550 °C was utilized for the favorable ‘Zone 2’ range for liquid oxide NMIs. This was because most of the steelmaking processes operate in the range of 1500 °C to 1600 °C. In a future work, it could be interesting to check the dynamic ‘liquid window’ as the operating temperature is vital in monitoring the steelmaking processes. Obtained experimental results from three steel grades were investigated based on reported SEN clogging events to check the relationship between the ‘Clog’ value and the reported SEN clogging conditions. Table VI shows the results obtained from this analysis. In reality, the proposed ‘Clog’ parameter was not highlighting the actual clogging behavior. However, it was necessary to check how effective this parameter could be in predicting the actual SEN clogging phenomena, since it is directly related to the transformation of NMIs.

The important here was to check whether the base concept behind the proposed modeling strategy would work in real steelmaking conditions. However, it was challenging to conclude anything regarding the SEN clogging tendency solely based on the ‘Clog’ value due to the stochastic nature of the SEN clogging phenomenon. Although a ‘Clog’ value between 1.25 and 3.25 could be best for the given steel grade for normal casting as most of the NMIs transformed to the liquid state, there should be some more investigations carried out before one can conclude that the ‘Clog’ value could assist in prediction of real SEN clogging events. It would also be interesting to modify the ‘Clog’ parameter by combining the factors associated with SEN stopper rods movements as reported by previous studies.[5,6,54]

The model predictive response in Figure 12 showed that at sampling stages S1 [refer to Figure 12(a)] and S2 [refer to Figure 12(b)], all four classes of Ca addition were required to modify the NMIs towards the liquid state and major dependency on the ‘Clog’ feature. This could give an idea to the operators before the actual Ca addition, in how much Ca inside the steel is required to satisfy the transformation of NMIs from solid to liquid state. This also indicates that the Ca addition in the steel was necessary for these steel grades to initiate a transformation of aluminum oxide NMIs based on the ‘Clog’ value. At sampling stage S3, just after the Ca was added, the model showed that only three classes were needed to transform the physical state of NMIs [refer to Figure 12(c)]. ‘Class 4’ referred to as the highest Ca addition, was not required at S3 since most of the solid aluminum oxide NMIs were transformed into liquid globular complex oxide inclusions. Although due to the Ca addition, at S3, the content of Ca rises in NMIs, depending on the steel grade, this could vary and cause additional losses if Ca addition is done in excess. Most importantly, under such conditions, the operator could get instant help from the model in calculating the best possible class of Ca addition required depending on the ‘Clog’ value. In this way, two things could be monitored continuously, the transformation of NMIs and the optimum quantity required for the Ca addition depending on the individual ‘heat’ of specific steelgrade. Model predictive response at S4 [refer to Figure 12(d)] for optimization of ‘Class 2’ was majorly dependable upon CA, along with ‘Clog’ value. This was because the parameter CA, total calcium inside steel and NMIs changed significantly after Ca addition. Similar tendencies regarding changes in the total calcium content at S4 were also found in the results obtained from OES-PDA experiments (refer to Figure 8).

The results obtained for grade 2 and grade 3 showed similar dependencies on input features where most of the model output was dependable on the ‘Clog’ value [refer Figures 13(b), (c)]. However, the model predictive response for grade 1 showed direct dependency on features ‘AL’ total aluminum inside the steel and the NMIs. ‘MG’ the total magnesium inside the steel and the NMIs, and ‘S’ the total sulfur inside the steel and the NMIs along with the ‘Clog’ value [refer Figure 13(a)]. This explained the importance of monitoring other process features apart from the ‘Clog’ parameter for the estimation of the class of Ca addition. The model predictive response showed that all four classes were needed for grade 1 and 3 to estimate the best class of Ca addition [refer Figures 13(a), (c)]. However, for grade 2, three classes, except class 4, were sufficient for estimating the best class [refer Figure 13(b)]. This observation also explained that different steel grades require different amounts of Ca addition to transform NMIs from solid to liquid and avoid SEN clogging. The above findings align with previous works and cover several key aspects. The role of calcium additions in modifying NMI composition was highlighted.[55] Additionally, the necessity for varying Ca levels across specific steel grades was emphasized.[56] The findings highlighted the role of steel chemistry[57,58,59] and its criticality for online process optimization.[60] The impact of solid oxide NMIs on SEN clogging[61,62] and their presence on casting interruptions[63] was considered.

(a) through (c) Plots showcasing the feature importance with feature effects on model predictive response for the studied steel grades; (a) Grade 1, (b) Grade 2, (c) Grade 3. (d) Plot showcasing the comparison of process planning using the conventional analyzing route and planning with proposed supervisory system named ‘ClogCalc’

To make decisions regarding process planning, operators rely today on the data obtained through the conventional sample analyzing route, which includes time-consuming steps, such as the transportation of samples to the laboratory, analyzing them through OES-PDA analysis, and reporting the analyzed data back to the control room [refer Figure 13(d)]. After examining the results, operators make the decision about the amount of Ca addition required. For such visualization of results and online monitoring of the ‘Clog’ value, a dashboard named ‘ClogCalc’ with the signal assistive output was designed and tested in laboratory environment within the Horizon 2020 project INEVITABLE. This dashboard was designed to accurately display the model predictive response in terms of signals and once fed with the necessary process data, help operators to make decisions regarding the amount of Ca addition. The computer codes behind required functions and ML models were designed and developed such that the implementation of this ‘ClogCalc’ monitoring dashboard can be done easily in any existing industrial IT architecture.

Conclusions

The preliminary work in this study showed that it was possible to develop a decision support system for in-process optimization of Ca addition using supervised machine learning. Both data analysis and domain knowledge drawn from laboratory experiments were used to design this novel ML-based decision support system. The data analysis was mainly used in the definition of the regression and classification approach, whereas metallurgical domain knowledge was of great help in setting the rules for the ‘liquid window’ and labeling classes of Ca addition. Many physics-driven models were developed in the past to estimate the optimum amount of Ca required for the modification of NMIs. Due to limited computational power and long calculations times, almost all of these models are only beneficial for process design, but cannot be implemented for process monitoring in real industrial scenarios. A key aspect of this work was the creation of the ‘Clog’ parameter, which serves as the main factor in determining the condition and changes in NMI’s shape. In addition, experimental and modeling results proved the significance of the ‘Clog’ parameter in predicting possible SEN clogging conditions. However, a more detailed investigation of the SEN clogging phenomenon has to be addressed in future studies to confirm this hypothesis. For example, it would be interesting to merge different time-dependent factors associated with SEN clogging as input parameters along with the developed data-driven strategy for the most realistic estimation of Ca additions. In addition, the next task will be to analyze the performance of the developed model on other steel grades and steel grade families, apart from the one studied in this work, as the proposed study already suggests a different amount of Ca addition for steel grades studied. Although the developed modeling strategy worked satisfying on the different heats of steel grades studied, it is essential to understand that every steel ‘heat’ is unique in itself, as every new heat produced gives newer insights about how the model could be tuned. Tracking changes in the processing parameters, which affect steelmaking is absolute for better process planning and control. This can only be achieved by developing models that rely on a data-centric approaches rather than a model-centric one. The authors believe that the work carried out in this study can be the first step towards ML model integration at steelworks which can help in quality improvement of the steel production by optimizing the Ca addition process. By incorporating factory physics, the proposed model can support operators in making dynamic decisions associated with the calcium treatment and plan strategies for eluding SEN clogging.

References

S. Dworak, H. Rechberger, and J. Fellner: Resour. Conserv. Recycl., 2022, vol. 179, p. 106072.

D.S. Andreiana, L.E. Acevedo Galicia, S. Ollila, C. Leyva Guerrero, Á. Ojeda Roldán, F. Dorado Navas, and A. del Real Torres: Processes, 2022, vol. 10, p. 434.

L.S. Carlsson, P.B. Samuelsson, and P.G. Jönsson: Metals, 2019, vol. 9, p. 959.

D. Cemernek, S. Cemernek, H. Gursch, A. Pandeshwar, T. Leitner, M. Berger, G. Klösch, and R. Kern: J. Intell. Manuf., 2022, vol. 33, pp. 1561–79.

H. Barati, M. Wu, A. Kharicha, and A. Ludwig: Powder Technol., 2018, vol. 329, pp. 181–98.

J. Ikäheimonen, K. Leiviskä, J. Ruuska, and J. Matkala: IFAC Proc., 2002, vol. 35, pp. 143–47.

P.R. Scheller and Q. Shu: Steel Res. Int., 2014, vol. 85, pp. 1310–16.

A.M. Wartiainen, M. Harju, S. Tamminen, L. Määttä, T. Alatarvas, and J. Röning: Open Eng., 2020, vol. 10, pp. 642–48.

B.A. Webler and P.C. Pistorius: Metall. Mater. Trans. B, 2020, vol. 51B, pp. 2437–52.

H.V. Atkinson and G. Shi: Prog. Mater. Sci., 2003, vol. 48, pp. 457–520.

P. Kaushik, M. Lowry, H. Yin, and H. Pielet: Ironmak. Steelmak., 2012, vol. 39, pp. 284–300.

L. Zhang and B.G. Thomas: ISIJ Int., 2003, vol. 43, pp. 271–91.

H. Du, A. Yang, A.V. Karasev, and P.G. Jönsson: Steel Res. Int., 2021, vol. 92, p. 2100223.

T. Lis: Metalurgija, 2009, vol. 48, pp. 95–98.

J.H. Park and L. Zhang: Metall. Mater. Trans. B, 2020, vol. 51B, pp. 2453–82.

L. Zhang, Q. Ren, H. Duan, Y. Ren, W. Chen, G. Cheng, W. Yang, and S. Sridhar: Miner. Process. Extr. Metall., 2020, vol. 129, pp. 184–206.

D. You, C. Bernhard, A. Mayerhofer, and S.K. Michelic: ISIJ Int., 2021, vol. 61, pp. 2991–97.

P. Mason, A.N. Grundy, R. Rettig, L. Kjellqvist, J. Jeppsson, and J. Bratberg: 11th International Symposium on High-Temperature Metallurgical Processing, 2020, pp. 101–13.

K. Tshilombo: Int. J. Miner. Metall. Mater., 2010, vol. 17, pp. 28–31.

J.H. Park and H. Todoroki: ISIJ Int., 2010, vol. 50, pp. 1333–46.

K. Sakata: ISIJ Int., 2006, vol. 46, pp. 1795–99.

N. Verma, P.C. Pistorius, R.J. Fruehan, M.S. Potter, H.G. Oltmann, and E.B. Pretorius: Metall. Mater. Trans. B, 2012, vol. 43B, pp. 830–40.

S.Y. Kitamura, K. Miyamura, and I. Fukuoka: Trans. Iron Steel Inst. Jpn., 1987, vol. 27, pp. 344–50.

K. Miao, M. Nabeel, and N. Dogan: Metall. Mater. Trans. B, 2022, vol. 53, pp. 1–17.

Y. Tabatabaei, K.S. Coley, G.A. Irons, and S. Sun: Steel Res. Int., 2019, vol. 90, pp. 1–14.

Y. Kanbe, A. Karasev, H. Todoroki, and P.G. Jönsson: ISIJ Int., 2011, vol. 51, pp. 593–602.

A. Karasev and H. Suito: Metall. Mater. Trans. B, 1999, vol. 30B, pp. 249–57.

H. Ohta and H. Suito: ISIJ Int., 2006, vol. 46, pp. 14–21.

D. Janis, P.G. Jönsson, A. Appell, and J. Janis: Ironmak. Steelmak., 2016, vol. 43, pp. 121–29.

A. Kaplan, H. Cao, J.M. FitzGerald, N. Iannotti, E. Yang, J.W.H. Kocks, K. Kostikas, D. Price, H.K. Reddel, I. Tsiligianni, C.F. Vogelmeier, P. Pfister, and P. Mastoridis: J. Allergy Clin. Immunol. Pract., 2021, vol. 9, pp. 2255–61.

Scopus. https://www.scopus.com/search/form.uri?display=basic#basic. Accessed 18 Mar 2022.

S. García, S. Ramírez-Gallego, J. Luengo, J.M. Benítez, and F. Herrera: Big Data Anal., 2016, vol. 1, p. 9.

I. Iguyon and A. Elisseeff: J. Mach. Learn. Res., 2003, vol. 3, pp. 1157–82.

A. Botchkarev: Interdiscip. J. Inf. Knowl. Manag., 2019, vol. 14, pp. 045–76.

F. Boto, M. Murua, T. Gutierrez, S. Casado, A. Carrillo, and A. Arteaga: Metals, 2022, vol. 12, p. 172.

M. Vannucci, V. Colla, G. Nastasi, and N. Matarese: Int. J. Simul. Syst. Sci. Technol., 2010, vol. 11, pp. 1–11.

M. Vannucci, V. Colla, and S. Cateni: International Work-Conference on Artificial Neural Networks, 2015, pp. 400–11.

S. Yang, A. Rebmann, M. Tang, R. Moravec, D. Behrmann, M. Baird, and B.W. Bequette: J. Process. Control, 2021, vol. 105, pp. 259–66.

C. Thornton, F. Hutter, H.H. Hoos, and K. Leyton-Brown: Proc. 19th ACM SIGKDD Int. Conf. Knowl. Discov. Data Min., 2013, pp. 847–55.

S. Kuthe, A. Karasev, B. Glaser, and R. Roman: ESTAD Conference, Stockholm, 2021.

M.R. Segal: Machine Learning Benchmarks and Random Forest Regression. UCSF: Center for Bioinformatics and Molecular Biostatistics, 2004. Retrieved from https://escholarship.org/uc/item/35x3v9t4.

Y. Tabatabaei, K.S. Coley, G.A. Irons, and S. Sun: Metall. Mater. Trans. B, 2018, vol. 49B, pp. 2022–37.

Y. Sahai: Metall. Mater. Trans. B, 2016, vol. 47B, pp. 2095–106.

W.F. Caley: High Temp. Mater. Process., 2006, vol. 25, pp. 157–66.

F. Tehovnik, J. Burja, B. Arh, and M. Knap: Metalurgija, 2015, vol. 54, pp. 371–74.

L. Zhang, Y. Liu, Y. Zhang, W. Yang, and W. Chen: Metall. Mater. Trans. B, 2018, vol. 49B, pp. 1841–59.

Y. Tanaka, F. Pahlevani, S.Y. Kitamura, K. Privat, and V. Sahajwalla: Metall. Mater. Trans. B, 2020, vol. 51B, pp. 1384–94.

H. Du: Evaluations of Non-metallic Inclusions in Ca-Treated Steels and Their Effect on the Machinability, Ph.D. Dissertation, KTH Royal Institute of Technology, 2021. Retrieved from https://urn.kb.se/resolve?urn=urn:nbn:se:kth:diva-291666

T. Yoshioka, K. Nakahata, T. Kawamura, and Y. Ohba: ISIJ Int., 2016, vol. 56, pp. 1973–81.

Y. Ren, L. Zhang, and S. Li: ISIJ Int., 2014, vol. 54, pp. 2772–79.

D. Janis. Doctoral Dissertation, KTH Royal Institute of Technology, 2015.

C. Liu, Y. Kacar, B. Webler, and P.C. Pistorius: Metall. Mater. Trans. B, 2021, vol. 52B, pp. 2837–41.

D. Janis, A. Karasev, and P.G. Jönsson: ISIJ Int., 2015, vol. 55, pp. 2173–81.

M. Rembold, O. Chahin, N. Ross, B. Williams, and R.J. O’Malley: Iron Steel Technol., 2015, vol. 12, pp. 43–51.

M.K. Sardar, S. Mukhopadhyay, U.K. Bandopadhyay, and S.K. Dhua: Steel Res. Int., 2007, vol. 78, pp. 136–40.

W. Wang, L. Zhang, Y. Ren, Y. Luo, X. Sun, and W. Yang: Metall. Mater. Trans. B, 2022, vol. 53B, pp. 1–7.

Z. Deng and M. Zhu: Steel Res. Int., 2013, vol. 84, pp. 519–25.

S. Wu, Y. Zhang, W. Yang, and L. Zhang: Steel Res. Int., 2022, vol. 93, p. 2200264.

D. Yang, X. Wang, G. Yang, P. Wei, and J. He: Steel Res. Int., 2014, vol. 85, pp. 1517–24.

W. Wang, J. Wang, Y. Ren, and L. Zhang: Steel Res. Int., 2023, vol. 94, p. 2200845.

V. Gollapalli, M.V. Rao, P.S. Karamched, C.R. Borra, G.G. Roy, and P. Srirangam: Ironmak. Steelmak., 2018, vol. 46, pp. 663–70.

L. Cheng, L. Zhang, Y. Ren, and W. Yang: Metall. Mater. Trans. B, 2021, vol. 52B, pp. 1186–93.

P. Ni, L.T.I. Jonsson, M. Ersson, and P.G. Jönsson: Metall. Mater. Trans. B, 2014, vol. 45B, pp. 2414–24.

Acknowledgments

The work presented in this paper is funded by the European Union’s Horizon 2020 research and innovation programme, the SPIRE initiative, under Grant Agreement No. 869815, the INEVITABLE project (‘Optimization and performance improving in metal industry by digital technologies’).

Funding

Open access funding provided by Royal Institute of Technology.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Appendix

Appendix

See Table AI.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kuthe, S., Rössler, R., Karasev, A. et al. Online Supervisory System for In-Process Optimization of Calcium Additions by Continuously Monitoring the State of Non-metallic Inclusions Inside Low-Alloyed Liquid Steels. Metall Mater Trans B 55, 1395–1413 (2024). https://doi.org/10.1007/s11663-024-03035-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-024-03035-z