Abstract

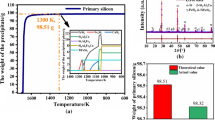

Decreasing the FeSi2 content is key to improving the (CH3)2SiCl2 yield when using high-iron metallurgical-grade silicon (MG-Si) as the raw material to synthesize silicone monomers. However, the FeSi2 content in MG-Si is already quite low, making it difficult to further reduce. Here, by adjusting the melt composition and using the transformation mechanism of Fe-containing intermetallics during solidification, the negative FeSi2 was transformed into positive Si8Al6Fe4Ca and harmless Si2Al3Fe, which avoided the adverse effects of FeSi2. The results showed that typical intermetallics in the high-iron MG-Si melt were FeSi2, Si2Al2Ca, and Si8Al6Fe4Ca. When the melt was cooled to 860 °C, the key reaction was 4Al + FeSi2 + 4Si2Al2Ca → Si8Al6Fe4Ca + 2Si, The remaining FeSi2 was transformed into Si2Al3Fe under the action of Al. After directional regulation, FeSi2 was almost completely removed from high-Fe MG-Si, and the average content of Si8Al6Fe4Ca increased from 0.12 to 0.50 wt pct, an increase of 4.17 times. This phase was treated by the directional regulation of FeSi2, which lays a theoretical foundation and provided technical support for the use of high-iron MG-Si as a raw material to synthesize silicone monomers.

Similar content being viewed by others

References

Y. Zhang, J. Li, H. Liu, Y. Ji, Z. Zhong, and F. Su: ChemCatChem, 2019, vol. 12(11), pp. 2757–79. https://doi.org/10.1002/cctc.201900385.

S. Li, X. Deng, J. Wen, K. Wei, and W. Ma: Intermetallics, 2021, vol. 128, p. 106987. https://doi.org/10.1016/j.intermet.2020.106987.

J. Xu, S. Song, Y. Zhu, J. Fang, Y. Ji, Z. Li, D. Fu, Z. Zhong, G. Xu, and F. Su: J. Catal., 2022, vol. 410, pp. 280–93. https://doi.org/10.1016/j.jcat.2022.04.026.

J.M. Bablin, A.C. Crawford, D.C. DeMoulpied, and L.N. Lewis: Ind. Eng. Chem. Res., 2003, vol. 15(42), pp. 3555–65. https://doi.org/10.1021/ie020334s.

S. Li, X. Long, L. Chen, and W. Qiu: J. Mater. Res. Technol., 2023, vol. 22, pp. 1911–23. https://doi.org/10.1016/j.jmrt.2022.12.051.

X. Deng, K. Wei, J. Wen, and W. Ma: J. Alloys Compd., 2022, vol. 890, p. 161832. https://doi.org/10.1016/j.jallcom.2021.161832.

S. Li, X. Deng, C. Zhang, J. Wen, J. Wu, K. Wei, and W. Ma: J. Alloys Compd., 2020, vol. 831, p. 154888. https://doi.org/10.1016/j.jallcom.2020.154888.

S. Yang, X. Wan, K. Wei, W. Ma, and Z. Wang: Waste Manag., 2020, vol. 120, pp. 820–27. https://doi.org/10.1016/j.wasman.2020.11.005.

S. Yang, X. Wan, K. Wei, W. Ma, and Z. Wang: Miner. Eng., 2021, vol. 169, p. 106966. https://doi.org/10.1016/j.mineng.2021.106966.

A. Hosseinpour and K.L. Tafaghod: Miner. Process. Extr. M, 2018, vol. 5(39), pp. 308–18. https://doi.org/10.1080/08827508.2018.1459616.

J. Wen, X. Deng, K. Wei, and W. Ma: Silicon, 2021. https://doi.org/10.1007/s12633-021-01341-8.

N. He, D. Yang, M. Xu, J. Wu, K. Wei, and W. Ma: Metall. Mater. Trans. B, 2021, vol. 52B, pp. 1830–38. https://doi.org/10.1007/s11663-021-02149-y.

D. Liu, X. Deng, J. Tai, S. Yang, K. Wei, and W. Ma: Silicon, 2022. https://doi.org/10.1007/s12633-022-01876-4.

Y. Zhao, K. Wei, S. Yang, W. Ma, and C. Xu: Silicon, 2023. https://doi.org/10.1007/s12633-023-02304-x.

H. Zhang, S. Guo, J. Wu, D. Wu, K. Wei, and W. Ma: Hydrometallurgy, 2021, vol. 204, p. 105715. https://doi.org/10.1016/j.hydromet.2021.105715.

F. Chigondo: Silicon, 2018, vol. 10, pp. 789–98. https://doi.org/10.1007/s12633-016-9532-7.

J. Hu, K. Zhu, K. Wei, W. Ma, and T. Lv: J. Alloys Compd., 2020, vol. 816, p. 152621. https://doi.org/10.1016/j.jallcom.2019.152621.

L. Zhou, K. Zhu, X. Deng, T. Yan, J. Hu, and K. Wei: Metall. Mater. Trans. B, 2022. https://doi.org/10.1007/s11663-022-02527-0.

Y. He, W. Ma, A. Xing, M. Hu, S. Liu, X. Yang, J. Li, S. Du, and W. Zhou: Mater. Sci. Semicond. Proc., 2022, vol. 141, p. 106438. https://doi.org/10.1016/j.mssp.2021.106438.

H. Chen, X. Yuan, K. Morita, Y. Zhong, X. Ma, Z. Chen, and Y. Wang: Metall. Mater. Trans. B, 2019, vol. 5(50), pp. 2088–94. https://doi.org/10.1007/s11663-019-01639-4.

M.D. Johnston, L.T. Khajavi, M. Li, S. Sokhanvaran, and M. Barati: JOM-US, 2012, vol. 64, pp. 935–45. https://doi.org/10.1007/s11837-012-0384-3.

F. Xi, S. Li, W. Ma, Z. Chen, K. Wei, and J. Wu: Hydrometallurgy, 2021, vol. 201, p. 105553. https://doi.org/10.1016/j.hydromet.2021.105553.

L. Zhou, K. Zhu, X. Deng, H. Zhang, and K. Wei: Metall. Mater. Trans. B, 2022. https://doi.org/10.1007/s11663-022-02701-4.

Y. Du, J.C. Schuster, Z.K. Liu, R. Hu, P. Nash, W. Sun, W. Zhang, J. Wang, L. Zhang, C. Tang, Z. Zhu, S. Liu, Y. Ouyang, W. Zhang, and N. Krendelsberger: Intermetallics, 2008, vol. 4(16), pp. 554–70. https://doi.org/10.1016/j.intermet.2008.01.003.

L. Zhou, K. Zhu, T. Yan, J. Hu, K. Wei, and W. Ma: Metall. Mater. Trans. B, 2022, vol. 53B, pp. 1283–94. https://doi.org/10.1007/s11663-021-02395-0.

L. Zhou, K. Wei, K. Zhu, X. Deng, H. Zhang, and W. Ma: Metall. Mater. Trans. B, 2023, vol. 54, pp. 2216–28. https://doi.org/10.1007/s11663-023-02828-y.

M. Zhu, S. Yue, G. Wu, K. Tang, Y. Xu, and J. Safarian: Sep. Purif. Technol., 2021, vol. 271, p. 118675. https://doi.org/10.1016/j.seppur.2021.118675.

J.C. Anglezio, C. Servant, and F. Dubrous: J. Mater. Res., 1990, vol. 9(5), pp. 1894–99. https://doi.org/10.1557/JMR.1990.1894.

K. Zhu, W. Ma, K. Wei, Y. Lei, J. Hu, T. Lv, and Y. Dai: J. Alloys Compd., 2018, vol. 750, pp. 102–10. https://doi.org/10.1016/j.jallcom.2018.02.161.

T. Yan, K. Zhu, L. Zhou, and K. Wei: Metall. Mater. Trans. B, 2022, vol. 53B(6), pp. 3745–56. https://doi.org/10.1007/s11663-022-02637-9.

Acknowledgments

This work was supported by the National Natural Science Foundation of China (No. U1902219), the Yunnan Young and Middle-aged Academic and Technical Leader Reserve Talent Project (No. 2018HB009), the Yunnan Distinguished Young Scholar Science Foundation (No. 202101AV070007), the Major Science and Technology Projects in Yunnan Province (No. 202002AB080002), the Sichuan Science and Technology Program (2021YJ0548), and the Research Project of Panzhihua University (2020ZD002).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhou, L., Wei, K., Zhu, K. et al. A Method for the Directional Regulation of FeSi2 in High-Iron Metallurgical-Grade Silicon. Metall Mater Trans B 54, 3426–3437 (2023). https://doi.org/10.1007/s11663-023-02920-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-023-02920-3