Abstract

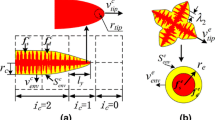

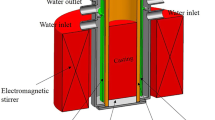

Strand electromagnetic stirring (SEMS) is widely applied in thin slab continuous casting to improve the equiaxed crystal ratio (ECR) of steel. To provide a deeper insight into the role of SEMS in controlling the flow pattern, superheat transportation, macrosegregation, and as-cast structure in the whole strand. A three-phase equiaxed-columnar solidification model was developed to predict the solidification process. The anisotropic permeability of directional columnar structures was integrated into the model by tracking the columnar growing direction. Numerical results showed that two recirculating flow regions came into being under the one-way moving magnetic field induced by the SEMS. The upward recirculating flow deflected the nozzle jet and assembled a superheat melt impinging towards the narrow face under the electromagnetic stirring. Level velocity and level height in the stirring direction were disturbed by the upward flow. Equiaxed grains formed in the stirring direction were less than the volume fraction on the other side. The one-way magnetic field also caused an asymmetric distribution of equiaxed grains in the thickness direction. Applying SEMS was beneficial to the improvement of ECR. The ECR in the strand was 4 pct in the absence of electromagnetic stirring, and it increased to 17.4 pct after applying the SEMS.

Similar content being viewed by others

Abbreviations

- \({\mathbf{B}}\) :

-

Magnetic flux density (T)

- \(c_{{\text{l}}}\), \(c_{{\text{e}}}\), \(c_{{\text{c}}}\) :

-

Species concentration (−)

- \(c_{{{\text{ref}}}}\) :

-

Reference concentration (−)

- \(c_{{\text{l}}}^{*}\), \(c_{{\text{s}}}^{*}\) :

-

Equilibrium concentration at interface (−)

- \(c_{{{\text{mix}}}}\) :

-

Mixed concentration (−)

- \(c_{\text{p}}\) :

-

Specific heat (J kg−1 K−1)

- \(C_{ji}^{{}}\)(\(= - C_{ij}\)):

-

Species exchange term (kg m−3 s−1)

- \(D_{{\text{l}}}\), \(D_{{\text{e}}}\), \(D_{{\text{c}}}\) :

-

Diffusion coefficient (m2 s−1)

- \({\mathbf{E}}\) :

-

Electric field intensity (V m−1)

- \(f_{{\text{l}}}\), \(f_{{\text{e}}}\), \(f_{{\text{c}}}\) :

-

Volume fraction (−)

- \({\mathbf{F}}_{ji}^{{}}\)(\(= - {\mathbf{F}}_{ij}\)):

-

Momentum exchange rate (kg m−2 s−2)

- \({\mathbf{F}}_{L}^{{}}\) :

-

Lorentz force (kg m−2 s−2)

- \({\mathbf{g}}\) :

-

Gravity (m s−2)

- \(h_{{\text{l}}}\), \(h_{{\text{e}}}\), \(h_{{\text{c}}}\) :

-

Enthalpy (J kg−1)

- \(H^{*}\) :

-

Heat transfer coefficient between phases (W m−3 K−1)

- \({\mathbf{H}}\) :

-

Magnetic field intensity (A m−1)

- \({\mathbf{j}}\) :

-

Induced current density (A m−2)

- \({\mathbf{J}}\) :

-

Current density (A m−2)

- \(k_{{\text{l}}}\), \(k_{{\text{e}}}\), \(k_{{\text{c}}}\) :

-

Thermal conductivity (W m−1 K−1)

- \( k_{{{\text{K}}\& {\text{C}}}} \) :

-

Kozeny–Carmen correlation constant (−)

- \( K_{{{\text{K}}\& {\text{C}}}} \) :

-

Mush permeability (m2)

- \({\mathbf{K}}_{\text{lc}}\) :

-

Anisotropic permeability tensor (m2)

- \(K_{\text{le}}\), \(K_{\text{ce}}\) :

-

Drag force coefficient (kg m−3 s−1)

- \(L\) :

-

Latent heat (J kg−1)

- \(m\) :

-

Liquidus line slope (K)

- \(M_{ji}\)(\(= - M_{ij}\)):

-

Mass transfer rate (kg m−3 s−1)

- \(n_{\text{e}}\) :

-

Nucleus number density (m−3)

- \(n_{\max }\) :

-

Maximum equiaxed grain density (m−3)

- \({\mathbf{n}}_{{\text{z}}}\) :

-

Unit vector in the casting direction (−)

- \({\mathbf{n}}_{{\text{f}}}\) :

-

Unit vector in the slab surface (−)

- \(N_{\text{nu}}\) :

-

Heterogeneous undercooling nucleation rate (m−3 s−1)

- \(N_{\text{frag}}\) :

-

Columnar fragmentation rate (m−3 s−1)

- \(p\) :

-

Pressure (Pa)

- \(Q_{ji}^{{}}\)(\(= - Q_{ij}\)):

-

Energy exchange term (W m−3)

- \(Q_{J}^{{}}\) :

-

Joule heat (W m−3)

- \(R_{{{\text{tip}}}}\) :

-

Primary columnar tip radius (m)

- \(S_{{\text{c}}}^{{}}\), \(S_{{\text{e}}}\) :

-

Interfacial area concentration of envelope (m−1)

- \(T_{{\text{l}}}\), \(T_{{\text{e}}}\), \(T_{{\text{c}}}\) :

-

Temperature (K)

- \(T_{{{\text{ref}}}}\) :

-

Reference temperature (K)

- \(\Delta T\) :

-

Constitutional undercooling (K)

- \(\Delta T_{\text{N}}\) :

-

Undercooling for maximum nucleation rate (K)

- \(\Delta T_{\sigma }\) :

-

Gaussian distribution width (K)

- \(U_{{{\text{cast}}}}\) :

-

Casting speed (m s−1)

- \(v_{{\text{c,tip}}}\) :

-

Growth speed of primary columnar tip (m s−1)

- \({\mathbf{v}}_{{\text{l}}}\), \({\mathbf{v}}_{{\text{e}}}\), \({\mathbf{v}}_{{\text{c}}}\), \({\mathbf{v}}_{{{\text{wall}}}}\) :

-

Velocity vector (m s−1)

- \(v_{Rc}\) :

-

Growth speed in the radius direction of columnar trunks (m s−1)

- \(v_{Re}\) :

-

Growth speed in the radius direction of equiaxed grains (m s−1)

- \(\beta_{{\text{T}}}\) :

-

Thermal expansion coefficient (K−1)

- \(\beta_{{\text{c}}}\) :

-

Solutal expansion coefficient (−)

- \(\sigma\), \(\sigma_{{\text{e}}}\), \(\sigma_{{\text{c}}}\) :

-

Electrical conductivity (S m−1)

- \(\Phi_{{{\text{imp}}}}^{{\text{c}}}\), \(\Phi_{{{\text{imp}}}}^{{\text{e}}}\) :

-

Growing surface impingement factor (−)

- \(\lambda_{1}\) :

-

Primary columnar arm space (m)

- \(\lambda_{2}\) :

-

Secondary columnar arm space (m)

- \(\mu_{{\text{l}}}\) :

-

Viscosity (kg m−1 s−1)

- \(\mu_{\text{mag}}\) :

-

Vacuum magnetic permeability (H m−1)

- \(\gamma\) :

-

Fragmentation coefficient (−)

- \(\rho\), \(\rho_{{\text{s}}}\) :

-

Density (kg m−3)

- \(\rho_{{{\text{ref}}}}\) :

-

Reference density (kg m−3)

- \(\tilde{\rho }\) :

-

Correction density (kg m−3)

- \(\varphi\) :

-

Electric potential (V)

- \({{\varvec{\uptau}}}_{i}\) :

-

Stress–strain tensors (kg m−1 s−1)

- c:

-

Columnar phase

- e:

-

Equiaxed phase

- l:

-

Liquid phase

References

H. Yu, Y.L. Kang, K.L. Wang, J. Fu, Z.B. Wang, and D.L. Liu: Mater. Sci. Eng. A, 2003, vol. 363, pp. 86–92. https://doi.org/10.1016/S0921-5093(03)00598-7.

P. Jayakrishna, S. Chakraborty, S. Ganguly, and P. Talukdar: Can. Metall. Q., 2021, vol. 60, pp. 320–49. https://doi.org/10.1080/00084433.2021.2014712.

B.K. Li and F. Tsukihashi: ISIJ Int., 2006, vol. 46, pp. 1833–38. https://doi.org/10.2355/isijinternational.46.1833.

R. Singh, B.G. Thomas, and S.P. Vanka: Metall. Mater. Trans. B, 2013, vol. 44B, pp. 1201–21. https://doi.org/10.1007/s11663-013-9877-x.

L.S. Zhang, X.F. Zhang, B. Wang, Q. Liu, and Z.G. Hu: Metall. Mater. Trans. B, 2014, vol. 45B, pp. 295–306. https://doi.org/10.1007/s11663-013-9948-z.

J. Sengupta, B.G. Thomas, H.J. Shin, G.G. Lee, and S.H. Kim: Metall. Mater. Trans. A, 2006, vol. 37A, pp. 1597–611. https://doi.org/10.1007/s11661-006-0103-1.

A. Vakhrushev, A. Kharicha, E. Karimi-Sibaki, M. Wu, A. Ludwig, G. Nitzl, Y. Tang, G. Hackl, J. Watzinger, and S. Eckert: Metall. Mater. Trans. B, 2021, vol. 52B, pp. 3193–3207. https://doi.org/10.1007/s11663-021-02247-x.

Z.Q. Liu, A. Vakhrushev, M.H. Wu, E. Karimi-Sibaki, A. Kharicha, A. Ludwig, and B.K. Li: Metals, 2018, vol. 8, p. 609. https://doi.org/10.3390/met8080609.

H. Shibata, S. Itoyama, Y. Kishimoto, S. Takeuchi, and H. Siekiguchi: ISIJ Int., 2006, vol. 46, pp. 921–30. https://doi.org/10.2355/isijinternational.46.921.

J. Gong, H.P. Liu, X.H. Wang, and Y.P. Bao: J. Iron. Steel Res. Int., 2015, vol. 22, pp. 414–22. https://doi.org/10.1016/s1006-706x(15)30021-2.

C.J. Wang, Z.Q. Liu, and B.K. Li: Metals, 2021, vol. 11, p. 948. https://doi.org/10.3390/met11060948.

Z. Zhang, M.H. Wu, H.J. Zhang, S. Hahn, F. Wimmer, A. Ludwig, and A. Kharicha: J. Mater. Process. Technol., 2022, vol. 301, p. 117434. https://doi.org/10.1016/j.jmatprotec.2021.117434.

T. Wang, L. Hachani, Y. Fautrelle, Y. Delannoy, E. Wang, X. Wang, and O. Budenkova: Int. J. Heat Mass Transf., 2020, vol. 151, p. 119414. https://doi.org/10.1016/j.ijheatmasstransfer.2020.119414.

Z.Q. Liu, R. Niu, Y.D. Wu, B.K. Li, Y. Gan, and M.H. Wu: Int. J. Heat Mass Transf., 2021, vol. 173, p. 121237. https://doi.org/10.1016/j.ijheatmasstransfer.2021.121237.

C.J. Wang, Z.Q. Liu, and B.K. Li: Int. J. Heat Mass Transf., 2022, vol. 194, p. 122974. https://doi.org/10.1016/j.ijheatmasstransfer.2022.122974.

L. Hachani, K. Zaidat, and Y. Fautrelle: Int. J. Heat Mass Transf., 2015, vol. 85, pp. 438–54. https://doi.org/10.1016/j.ijheatmasstransfer.2015.01.145.

H.H. Ge, F.L. Ren, J. Li, X.J. Han, M.X. Xia, and J.G. Li: Metall. Mater. Trans. A, 2017, vol. 48A, pp. 1139–50. https://doi.org/10.1007/s11661-016-3910-z.

J. Li, M.H. Wu, A. Ludwig, and A. Kharicha: Int. J. Heat Mass Transf., 2014, vol. 72, pp. 668–79. https://doi.org/10.1016/j.ijheatmasstransfer.2013.08.079.

M.H. Wu, J. Domitner, and A. Ludwig: Metall. Mater. Trans. A, 2012, vol. 43A, pp. 945–64. https://doi.org/10.1007/s11661-011-0940-4.

D.B. Jiang and M.Y. Zhu: Metall. Mater. Trans. B, 2016, vol. 47, pp. 3446–58. https://doi.org/10.1007/s11663-016-0772-0.

D.B. Jiang and M.Y. Zhu: Metall. Mater. Trans. B, 2017, vol. 48B, pp. 444–55. https://doi.org/10.1007/s11663-016-0864-x.

D.B. Jiang, W.L. Wang, S. Luo, C. Ji, and M.Y. Zhu: Metall. Mater. Trans. B, 2017, vol. 48B, pp. 3120–31. https://doi.org/10.1007/s11663-017-1104-8.

R. Guan, C. Ji, M.Y. Zhu, and S.M. Deng: Metall. Mater. Trans. B, 2018, vol. 49B, pp. 2571–83. https://doi.org/10.1007/s11663-018-1352-2.

J. Lipton, M.E. Glicksman, and W. Kurz: Mater. Sci. Eng., 1984, vol. 65, pp. 57–63. https://doi.org/10.1016/0025-5416(84)90199-x.

T. Wang, S. Semenov, E.G. Wang, Y. Delannoy, Y. Fautrelle, and O. Budenkova: Metall. Mater. Trans. B, 2019, vol. 50B, pp. 3039–54. https://doi.org/10.1007/s11663-019-01703-z.

A. Vakhrushev, M.H. Wu, A. Ludwig, Y. Tang, G. Hackl, and G. Nitzl: Metall. Mater. Trans. B, 2014, vol. 45B, pp. 1024–37. https://doi.org/10.1007/s11663-014-0030-2.

A. Ludwig and M.H. Wu: Metall. Mater. Trans. A, 2002, vol. 33A, pp. 3673–83. https://doi.org/10.1007/s11661-002-0241-z.

Y.J. Zheng, M.H. Wu, A. Kharicha, and A. Ludwig: Modell. Simul. Mater. Sci. Eng., 2018, vol. 26, p. 015004. https://doi.org/10.1088/1361-651X/aa86c5.

C.M.G. Rodrigues, M.H. Wu, H.J. Zhang, A. Ludwig, and A. Kharicha: Metall. Mater. Trans. A, 2021, vol. 52A, pp. 4609–622. https://doi.org/10.1007/s11661-021-06414-2.

M.H. Wu, A. Fjeld, and A. Ludwig: Comput. Mater. Sci, 2010, vol. 50, pp. 32–42. https://doi.org/10.1016/j.commatsci.2010.07.005.

T. Takaki, S. Sakane, M. Ohno, Y. Shibuta, and T. Aoki: Acta Mater., 2019, vol. 164, pp. 237–49. https://doi.org/10.1016/j.actamat.2018.10.039.

Y. Mitsuyama, T. Takaki, S. Sakane, Y. Shibuta, and M. Ohno: Acta Mater., 2020, vol. 188, pp. 282–87. https://doi.org/10.1016/j.actamat.2020.02.016.

C.Y. Wang, S. Ahuja, C. Beckermann, and H.C. Degroh: Metall. Mater. Trans. B, 1995, vol. 26B, pp. 111–19. https://doi.org/10.1007/Bf02648984.

B. Petrus, K. Zheng, X. Zhou, B.G. Thomas, and J. Bentsman: Metall. Mater. Trans. B, 2011, vol. 42B, pp. 87–103. https://doi.org/10.1007/s11663-010-9452-7.

Thermo-Calc Software TCFE7 Steels/Fe-alloys Database, https://thermocalc.com/products/databases/steel-and-fe-alloys/.

K. Timmel, S. Eckert, G. Gerbeth, F. Stefani, and T. Wondrak: ISIJ Int., 2010, vol. 50, pp. 1134–41. https://doi.org/10.2355/isijinternational.50.1134.

E. Cadirli and M. Gunduz: J. Mater. Sci., 2000, vol. 35, pp. 3837–48. https://doi.org/10.1023/A:1004829413966.

R. Moreau: Magnetohydrodynamics, Kluwer Academic Publishers, Norwell, 1990.

K. Cukierski and B.G. Thomas: Metall. Mater. Trans. B, 2008, vol. 39B, pp. 94–107. https://doi.org/10.1007/s11663-007-9109-3.

J.E. Camporredondo, A.H. Castillejos, F.A. Acosta, E.P. Gutiérrez, and M.A. Herrera: Metall. Mater. Trans. B, 2004, vol. 35B, pp. 541–60. https://doi.org/10.1007/s11663-004-0054-0.

Funding

This work was supported by the National Natural Science Foundation of China (No. 51974071), National Key Research and Development Program of China (No. 2022YFB3705101), and the Opening project fund of Materials Service Safety Assessment Facilities (No. MSAF-2021-009).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, C., Liu, Z. & Li, B. Study on the Effect of SEMS on the As-Cast Structure of Steel in Thin Slab Continuous Casting Using an Equiaxed-Columnar Solidification Model. Metall Mater Trans B 54, 3240–3258 (2023). https://doi.org/10.1007/s11663-023-02904-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-023-02904-3