Abstract

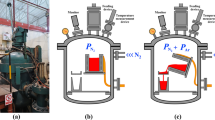

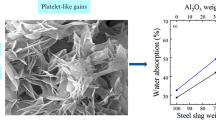

This paper presents a method based on Darcy’s law to determine the pressure drop between the dendrite tip and root during the formation of porosity. After verification by the measurement result of the porosity region in 30Cr15Mo1N ingot, this method is employed to investigate the change in the pressure drop with solidification pressure, considering various factors such as the second dendrite arm spacing, solid fraction, cooling rate, temperature gradient, density, liquidus temperature, and solidus temperature. The relationship between the pressure drop and solidification pressure determines the formation of porosity. The results demonstrate that as the solidification pressure increases from 0.3 to 0.7 MPa, the pressure drop decreases from 1.572 to 0.676 MPa. When the solidification pressure is below 0.6 MPa, the pressure drop consistently exceeds the solidification pressure, leading to inadequate interdendritic feeding of the molten steel and subsequent porosity formation. Conversely, when the solidification pressure ranges between 0.6 and 0.7 MPa, the pressure drop undergoes minimal change and is approximately equal to the solidification pressure, which leads to sufficient interdendritic feeding. Consequently, increasing the solidification pressure effectively suppresses the formation of porosity by reducing the hindrance to molten steel feeding and enhancing its feeding capacity. Furthermore, a more accurate determination of the constant kC was obtained to calculate the pressure drop in 30Cr15Mo1N ingot, within the range of 2.77 to 3.11.

Similar content being viewed by others

References

C.M. Tomasello and J.L. Maloney III.: Adv. Mater. Processes, 1998, vol. 154(1), pp. 58–60.

Z.Y. He, H.B. Li, Z.W. Ni, H.C. Zhu, Z.H. Jiang, H. Feng, and D.S. Mao: Steel Res. Int., 2021, vol. 92, p. 2100197.

W. Trojahn, E. Streit, H.A. Chin, and D. Ehlert: Materialwiss. Werkstofftech., 1999, vol. 30, pp. 605–11.

M.B. Horovitz, F.B. Neto, A. Garbogini, and A.P. Tcshiptschin: ISIJ Int., 1996, vol. 36, pp. 840–45.

H.B. Li, Z.Y. He, H.C. Zhu, H. Feng, Z.H. Jiang, Y. Wang, Z.W. Ni, and Y.B. Dai: Metall. Mater. Trans. B, 2022, vol. 53B, pp. 1721–32.

H.C. Zhu, H.B. Li, Z.W. Ni, Z.Y. He, Z.H. Jiang, H. Feng, S.C. Zhang, and D.S. Mao: Metall. Mater. Trans. B, 2022, vol. 53B, pp. 50–59.

L. Zhao, H.C. Liao, Y. Pan, L. Wang, and Q.G. Wang: Scr. Mater., 2011, vol. 65, pp. 795–98.

Q.G. Wang, D. Apelian, and D.A. Lados: J. Light Met., 2001, vol. 1, pp. 73–84.

Q.Y. Zhang, D.K. Sun, S.Y. Pan, and M.F. Zhu: Int. J. Heat Mass Transf., 2020, vol. 146, 118838.

G. Arzumanyan: J. Cryst. Growth, 1990, vol. 99, pp. 859–63.

S.C. Zhang, J.T. Yu, H.B. Li, Z.H. Jiang, Y.F. Geng, H. Feng, B.B. Zhang, and H.C. Zhu: J. Mater. Sci. Technol., 2022, vol. 102, pp. 105–114.

H.C. Zhu, Z.H. Jiang, H.B. Li, H. Feng, S.C. Zhang, G.H. Liu, J.H. Zhu, P.B. Wang, B.B. Zhang, and G.W. Fan: Metall. Mater. Trans. B, 2017, vol. 48B, pp. 2493–2503.

M.R. Ridolfi and O. Tassa: Intermetallics, 2003, vol. 11, pp. 1335–38.

H. Feng, H.B. Li, J. Dai, Y. Han, J.D. Qu, Z.H. Jiang, Y. Zhao, and T. Zhang: Corros. Sci., 2022, vol. 204, 110396.

H.B. Li, Y. Han, H. Feng, G. Zhou, Z.H. Jiang, M.H. Cai, Y.Z. Li, and M.X. Huang: J. Mater. Sci. Technol., 2023, vol. 141, pp. 184–92.

M.C. Flemings: Metall. Trans., 1974, vol. 5(10), pp. 2121–34.

J.J. Sobczak, L. Drenchev, and R. Asthana: Int. J. Cast Met. Res., 2013, vol. 25(1), pp. 1–14.

A.F. Ilkhchy, M. Jabbari, and P. Davami: Int. Commun. Heat Mass Transf., 2012, vol. 39(5), pp. 705–12.

G.S. Li, W. Yu, and Q.W. Cai: J. Mater. Process. Technol., 2016, vol. 227, pp. 41–48.

H.C. Zhu, Z.H. Jiang, H.B. Li, H. Feng, W.C. Jiao, S.C. Zhang, P.B. Wang, and J.H. Zhu: ISIJ Int., 2018, vol. 58(7), pp. 1267–74.

V. Khalajzadeh and C. Beckermann: Metall. Mater. Trans. A, 2020, vol. 51A, pp. 2239–54.

V. Khalajzadeh, K.D. Carlson, D.G. Backman, and C. Beckermann: Metall. Mater. Trans. A, 2017, vol. 48A, pp. 1797–1816.

H.B. Tao, H. Zhang, and M.L. Wang: Ironmak. Steelmak., 2020, vol. 47(4), pp. 351–60.

J.A. Taylor, G.B. Schaffer, and D.H. StJohn: Metall. Mater. Trans. A, 1999, vol. 30A, pp. 1643–50.

K.D. Carlson and C. Beckermann: Metall. Mater. Trans. A, 2009, vol. 40A, pp. 163–75.

D. Blondheim and A. Monroe: Int. J. Metalcast., 2022, vol. 16(1), pp. 330–41.

S. Bhagavath, B. Cai, R. Atwood, M. Li, B. Ghaffari, P.D. Lee, and S. Karagadde: Metall Mater. Trans. A, 2019, vol. 50A, pp. 4891–99.

Y.F. Zhang, J. Zheng, Y.T. Xia, H.G. Shou, W. Tan, W.J. Han, and Q. Liu: Mater. Sci. Eng. A, 2020, vol. 772, 138781.

N. Tenaglia, R. Boeri, G. Rivera, and J. Massone: Int. J. Cast Met. Res., 2016, vol. 29(1–2), pp. 112–20.

Y.W. Lee, E. Chang, and C.F. Chieu: Metall. Trans. B, 1990, vol. 21(4), pp. 715–22.

Z.Y. He, H.B. Li, H.C. Zhu, Y. Wang, Z.W. Ni, Z.H. Jiang, H. Feng, and S.C. Zhang, Metall. Mater. Trans. B, 2022, pp. 1–8.

H.C. Zhu, H.B. Li, Z.Y. He, H. Feng, and Z.H. Jiang: Metall. Mater. Trans. B, 2021, vol. 52B, pp. 3235–45.

Ch. Pequet, M. Rappaz, and M. Gremaud: Metall. Mater. Trans. A, 2002, vol. 33A, pp. 2095–2106.

W. Kurz, C. Bezençon, and M. Gäumann: Sci. Technol. Adv. Mater., 2001, vol. 2(1), pp. 185–91.

X.B. Li, S. Xiong, and Z. Guo: J. Mater. Sci. Technol., 2016, vol. 32(1), pp. 54–61.

B. Goyeau, D. Gobin, T. Benihaddadene, and M. Quintard: Metall Mater. Trans. B, 1999, vol. 30B, pp. 613–22.

K. Murakami, A. Shiraishi, and T. Okamoto: Acta Metall., 1983, vol. 31(9), pp. 1417–24.

Y. Natsume, D. Takahashi, K. Kawashima, E. Tanigawa, and K. Ohsasa: ISIJ Int, 2014, vol. 54(2), pp. 366–73.

S. Whitaker: Transp. Porous Med., 1986, vol. 1(1), pp. 3–25.

S. Mirbagheri and J. Silk: Mater. Des., 2007, vol. 28(1), pp. 356–61.

H. Darcy, Les fontaines publiques de la ville de Dijon: Exposition et application des principes à suivre et des formules à employer dans les questions de distribution d'eau: Ouvrage terminé par un appendice relatif aux fournitures d'eau de plusieurs villes, au filtrage des eaux et à la fabrication des tuyaux de fonte, de plomb, de tôle et de bitumen, vol. 2. 1856: V. Dalmont.

D.M. Stefanescu: Int. J. Cast Met. Res., 2005, vol. 18(3), pp. 129–43.

S. Brown, J. Spittle, D. Jarvis, and R. Walden-Bevan: Acta Mater., 2002, vol. 50(6), pp. 1559–69.

E. Khajeh and D.M. Maijer: Modell. Simul. Mater. Sci. Eng., 2012, vol. 20(3), p. 035004.

E. Khajeh and D.M. Maijer: Acta Mater., 2010, vol. 58(19), pp. 6334–44.

H.C. Zhu, H.B. Li, Z.Y. He, H. Feng, Z.H. Jiang, and T. He: ISIJ Int., 2021, vol. 61, pp. 1889–98.

H.C. Zhu, Z.H. Jiang, H.B. Li, P.B. Wang, and J.H. Zhu: Steel Res. Int., 2018, vol. 89(5), p. 1700475.

H.C. Zhu, H.B. Li, Z.H. Jiang, Z.Y. He, H. Feng, and S.C. Zhang: ISIJ Int., 2020, vol. 60(9), pp. 1978–84.

Y. Mitsuyama, T. Takaki, S. Sakane, Y. Shibuta, and M. Ohno: Acta Mater., 2020, vol. 188(15), pp. 282–87.

Acknowledgments

This research was sponsored by the National Natural Science Foundation of China [Grant Nos. U1960203/52325406/52374330], Science Fund for Distinguished Young Scholars of Liaoning Province [Grant No. 2023JH6/100500008], Fundamental Research Funds for the Central Universities [Grant No. N2125017] and Program of Introducing Talents of Discipline to Universities [Grant No. B21001].

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

He, ZY., Li, HB., Zhu, HC. et al. Investigation on Porosity Formation With Pressure Drop Between Dendrite Tip and Root During Pressurized Solidification of 30Cr15Mo1N Ingot. Metall Mater Trans B 54, 3155–3163 (2023). https://doi.org/10.1007/s11663-023-02898-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-023-02898-y