Abstract

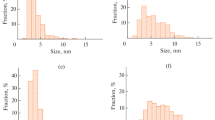

Non-metallic inclusions in steel disrupt the continuity of the matrix and decrease the strength and toughness of steel. This study analyzed the composition of the inclusion and two-dimensional size distribution in 15-5PH stainless steel using an automatic inclusion analysis system. The results showed that the composition was determined to be mainly Al–Si–Mn–O composites, and the average area, average equivalent diameter, and face fraction percentage of were 39.35 μm2, 5.86 μm, and 0.031 pct, respectively. The three-dimensional (3D) morphology and spatial distribution of the inclusions were further demonstrated using 3D microscopy (3D-XRM). The average volume, equivalent diameter, and volume fraction were 215.83 μm3, 7.44 μm, and 0.023 pct, respectively. Compared to SEM, 3D-XRM could obtain the internal information of the sample non-destructively and display the 3D morphology of inclusions more intuitively. Subsequently, the morphology, aspect ratio and spatial orientation of the inclusions at 1453 K under different deformation ratios were compared using 3D-XRM. As compression increased, the 3D morphology changed from spherical to flat, and the average aspect ratio and spatial orientation angle of the inclusions gradually increased, which indicated that the inclusions have excellent deformation ability. The deformability of the inclusions first increased and then decreased with the increasing of compression especially the large ones.

Similar content being viewed by others

References

Y. Ren, W. Yang, and L.F. Zhang: ISIJ Int., 2022, vol. 62, pp. 2159–71.

H.L. Yu, X.H. Liu, H.Y. Bi, and L.Q. Chen: J. Mater. Process. Technol., 2009, vol. 209, pp. 455–61.

C.H. Luo and U. Stahlberg: J. Mater. Process. Technol., 2001, vol. 114, pp. 87–97.

A. Rajput and S.K. Paul: J. Alloys Compds, 2021, vol. 869, p. 159213.

R. Higuchi, I. Hayashi, T. Yokozeki, and T. Aoki: Int. J. Solids Struct., 2022, vol. 234–235, p. 111291.

Q. Ren, L.F. Zhang, and W. Yang: Steel Res. Int., 2018, vol. 89, p. 1800047.

V. Vignal, R. Oltra, and C. Josse: Scripta Mater., 2003, vol. 49, pp. 779–84.

Y. Wang, Y.G. Yang, Z.H. Dong, J.H. Park, Z.L. Mi, X.P. Mao, and W.Z. Mu: Metall. Mater. Trans. B, 2022, vol. 53B, pp. 2182–97.

R. Cheng, J.M. Zhang, and B. Wang: Trans. Indian Inst. Met., 2017, vol. 71, pp. 705–13.

S.B. Hosseini, C. Temmel, B. Karlsson, and N.G. Ingesten: Metall. Mater. Trans. A, 2007, vol. 38A, pp. 982–89.

M. Yilmaz and H.M. Ertunc: Mater. Des., 2007, vol. 28, pp. 599–608.

B.H. Yuan, J.H. Liu, J.H. Zeng, M. Zhang, J.H. Huang, and X.D. Yang: Metals, 2022, vol. 12, p. 434.

Z.H. Zhan, W.F. Zhang, Y.L. Zhang, R.X. Shi, and G.G. Cheng: Metals, 2021, vol. 11, p. 1129.

J. Guo, K.M. Fang, H.J. Guo, Y.E. Luo, S.C. Duan, X. Shi, and W.S. Yang: Metals, 2018, vol. 8, p. 68.

X.Q. Pan, J. Yang, J.H. Park, and H. Ono: Int. J. Miner. Metall. Mater., 2020, vol. 27, pp. 1489–98.

S.R. Babu and S.K. Michelic: Materials (Basel), 2022, vol. 15, p. 3367.

H. Singh, A.M. Gokhale, Y. Mao, A. Tewari, and A.K. Sachdev: Metall. Mater. Trans. B, 2009, vol. 40B, pp. 859–70.

E.T.V. Bezerra, K.S. Augusto, and S. Paciornik: REM Int. Eng. J., 2020, vol. 73, pp. 197–203.

S.C. Wu, J.G. Bao, W.J. Qian, S. Karabal, W. Sun, and P.J. Withers: Int. J. Fatigue, 2021, vol. 151, p. 106317.

C.Q. Zhang and J.H. Li: At. Spectrosc., 2022, vol. 43, pp. 284–91.

P. Fan, S.L. Cockcroft, D.M. Maijer, L. Yao, C. Reilly, and A.B. Phillion: Metall. Mater. Trans. B, 2019, vol. 50B, pp. 2421–35.

L.X. Cui, X.H. Lei, L.F. Zhang, Y.X. Zhang, W. Yang, Y. Gao, and F.G. Liu: Metall. Mater. Trans. B, 2021, vol. 52B, pp. 2327–40.

Z.Y. Hu, X.H. Lei, L.F. Zhang, W. Yang, Y.H. Zhang, and Y. Gao: Metall. Mater. Trans. B, 2022, vol. 53B, pp. 1603–16.

N.L. Simon, X.L. Zhang, W. Tucker, H.K. Lee, T. Selly, and J.D. Schiffbauer: Mater. Charact., 2019, vol. 158, p. 109991.

K.A. Williams, D.M. McKay Fletcher, C. Petroselli, S.A. Ruiz, and T. Roose: Sci. Rep., 2022, vol. 12, p. 15891.

H.L. Yu, X. Cai, Z. Cao, X. Jiao, W. Xie, H.L. Yu, and P. Feng: Mater. Charact., 2022, vol. 190, p. 112062.

Y. Wang, L.F. Zhang, Y. Ren, Z.S. Li, C. Slater, K.Y. Peng, F.G. Liu, and Y.Y. Zhao: Metall. Mater. Trans. B, 2021, vol. 52B, pp. 1200–06.

F. Chai, H. Su, C.F. Yang, and D.M. Xue: J. Iron Steel Res. Int., 2014, vol. 21, pp. 369–74.

R. Wagner, M. Seleznev, H. Fischer, R. Ditscherlein, H. Becker, B.G. Dietrich, A. Keßler, T. Leißner, G. Wolf, A. Leineweber, U.A. Peuker, H. Biermann, and A. Weidner: Mater. Charact., 2021, vol. 174, p. 111039.

W.F. Zhang, G.B. Wang, Y.L. Zhang, G.G. Cheng, and Z.H. Zhan: Metals, 2022, vol. 12, p. 295.

W. Yang, K.Y. Peng, L.F. Zhang, and Q. Ren: J. Mater. Res. Technol., 2020, vol. 9, pp. 15016–22.

C.H. Luo and U. Stahlberg: Scand. J. Metall., 2002, vol. 31, pp. 184–90.

Acknowledgments

The authors are grateful for the support from the National Natural Science Foundation of China (Grant Nos. 51834002 and 52104320).

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

(MP4 65893 kb)

(MP4 36183 kb)

(MP4 19549 kb)

(MP4 19875 kb)

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, Q., Zhan, Z., Gao, M. et al. Investigation of Evolution of Inclusions in 15-5PH Stainless Steel During Hot Compression Using 3D X-Ray Microscopy. Metall Mater Trans B 54, 2852–2863 (2023). https://doi.org/10.1007/s11663-023-02882-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-023-02882-6