Abstract

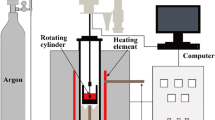

The spectral experiment, hemispherical melting point apparatus, rotating cylinder method, and four-probe method were conducted to measure the structure, melting temperature, viscosity, and electrical conductivity of aluminate slag. The results show that with F− content increase from 2 to 10 wt pct, the hemispherical melting point depresses, and the structure depolymerizes, leading to reduce of viscosity and augment of electrical conductivity. With further increase of F− content from 10 to 14 wt pct, both the hemispherical melting point and the network structure associated with Si and B polymerization turn upward, so the viscosity enhances. However, the electrical conductivity continuously augments due to the diluent effect of CaF2, that the loose CaF2 cluster structure is facilitated. Meanwhile, with the addition of F− within 10 wt pct, the crystalline phase changes from BaAl2O4 to Ca12Al14O33 and the intensity of the Bragg diffraction peak decreases, resulting in a decline in the breaking temperature (Tbr) of apparent viscosity–temperature curve. When the F− content exceeds 10 wt pct, the crystalline phase transforms into CaF2 and the intensity of the crystal peak is heightened, making Tbr enhance. Moreover, the apparent crystallization ratio also decreases and then increases.

Similar content being viewed by others

References

K.C. Mills and A.B. Fox: ISIJ Int., 2003, vol. 43, pp. 1479–86.

H.S. Park, H. Kim, and I. Sohn: Metall. Mater. Trans. B, 2011, vol. 42B, pp. 324–30.

H. Kim and I. Sohn: ISIJ Int., 2011, vol. 51, pp. 1–8.

G.H. Kim and I. Sohn: Metall. Mater. Trans. B, 2011, vol. 42B, pp. 1218–223.

M.K. Oh, T.S. Kim, and J.H. Park: Metall. Mater. Trans. B, 2020, vol. 51B, pp. 3028–38.

G.H. Kim and I. Sohn: J. Am. Ceram. Soc., 2019, vol. 102, pp. 6575–90.

G.H. Kim and I. Sohn: J. Mater. Res. Technol., 2022, vol. 20, pp. 2335–47.

S. Lee and D.J. Min: J. Am. Ceram. Soc., 2017, vol. 100, pp. 2543–52.

X. Zhang, C. Liu, and M. Jiang: ISIJ Int., 2020, vol. 60, pp. 2176–82.

S. He, S. Wang, B. Jia, M. Li, Q. Wang, and Q. Wang: Metall. Mater. Trans. B, 2019, vol. 50B, pp. 1503–13.

Y. Lao, Y. Gao, F. Deng, Q. Wang, and G. Li: Metall. Res. Technol., 2019, vol. 116, p. 638.

K.J. Schumacher, J.F. White, and J.P. Downey: Metall. Mater. Trans. B, 2015, vol. 46B, pp. 119–24.

Y.H. Lin, L.Q. Zhang, and X.L. Huang: Metall. Res. Technol., 2017, vol. 114, p. 606.

F. Shahbazian: Scand. J. Metall., 2001, vol. 30, pp. 302–08.

W. Xin, J. Zhang, Y. Deng, Y. Jiang, and P. Wang: Trans. Indian Inst. Met., 2021, vol. 74, pp. 871–79.

J.H. Park, D.J. Min, and H.S. Song: Metall. Mater. Trans. B, 2002, vol. 33B, pp. 723–29.

X. Wang, H. Jin, L. Zhu, Y. Xu, and S. Qu: Metals, 2019, vol. 9, p. 871.

J.S. Choi, T.J. Park, and D.J. Min: J. Am. Ceram. Soc., 2021, vol. 104, pp. 140–56.

J. Qi, C. Liu, C. Li, and M. Jiang: J. Rare Earths, 2016, vol. 34, pp. 328–35.

Q. Wang, J.A. Yang, C. Zhang, D.X. Cai, and O. Ostrovski: J. Iron Steel Res. Int., 2019, vol. 26, pp. 374–84.

J. Yang, J. Zhang, O. Ostrovski, C. Zhang, and D. Cai: Metall. Mater. Trans. B, 2019, vol. 50B, pp. 1766–72.

H. Shao, E. Gao, W. Wang, and L. Zhang: J. Am. Ceram. Soc., 2019, vol. 102, pp. 4440–49.

X. Zhang, C. Liu, and M. Jiang: J. Northeast. Univ. (Nat. Sci.), 2020, vol. 41, pp. 510–15.

G. Fan, S. He, T. Wu, and Q. Wang: Metall. Mater. Trans. B, 2015, vol. 46B, pp. 2005–13.

T. Wu, Q. Wang, S. He, J. Xu, X. Long, and Y. Lu: Steel Res. Int., 2012, vol. 83, pp. 1194–02.

X. Yu, G. Wen, P. Tang, and H. Wang: Chin. J. Process. Eng., 2010, vol. 10, pp. 1153–57.

W. Yan, W. Chen, Y. Yang, and A. McLean: Ironmak. Steelmak., 2019, vol. 46, pp. 347–52.

W. Yan, A. McLean, Y. Yang, W. Chen and M. Barati: Evaluation of mold flux for continuous casting of high-aluminum steel, Advances in Molten Slags, Fluxes, and Salts: Proceedings of the 10th International Conference on Molten Slags, Fluxes and Salts, Springer. 2016, pp. 279–89.

K.W. Peng, P. Zhang, J.G. Xie and H.L. Ma: Study on properties of Al2O3-CaO-SiO2-CaF2 slag system. Advanced Materials Research, Switzerland, 2012, Trans Tech Publ, pp. 269-272.

B. Lu and W. Wang: Metall. Mater. Trans. B, 2015, vol. 46B, pp. 852–62.

W. Yan, W. Chen, Y. Yang, C. Lippold, and A. McLean: Ironmak. Steelmak., 2016, vol. 43, pp. 316–23.

L. Fan, C. Liu, and M. Jiang: Metall. Mater. Trans. B, 2022, vol. 53B, pp. 1295–07.

C. Zhang, Y. Kong, T. Wu, G. Bao, J. Lei, and H. Wang: Metall. Res. Technol., 2022, vol. 119, p. 507.

Y. Sasaki, M. Iguchi, and M. Hino: ISIJ Int., 2007, vol. 47, pp. 346–47.

H. Singh, Q. Shu, G. King, Z. Liang, Z. Wang, W. Cao, M. Huttula, and T. Fabritius: J. Am. Ceram. Soc., 2021, vol. 104, pp. 4505–17.

X. Wan, C. Shi, Y. Huang, Q. Shu, and Y. Zhao: Metall. Mater. Trans. B., 2023, vol. 54B, pp. 465–79.

R. El Hayek, F. Ferey, P. Florian, A. Pisch, and D.R. Neuville: Chem. Geol., 2017, vol. 461, pp. 75–81.

C. Zhang, Y. Kong, T. Wu, J. Lei, G. Bao, and H. Wang: J. Mol. Liq., 2022, vol. 368, p. 120738.

J. Yang, J. Zhang, O. Ostrovski, C. Zhang, and D. Cai: Metall. Mater. Trans. B., 2019, vol. 50B, pp. 291–303.

J. Lei, W. Yang, G.Y. Sheng, C. Zhang, T. Wu, and H.C. Wang: Metall. Mater. Trans. B, 2022, vol. 2022B, pp. 1–9.

G.D. Chryssikos, E.I. Kamitsos, and A.P. Patsis: J. Non-Cryst. Solids, 1996, vol. 202, pp. 222–32.

L.M. Osipova, A.A. Osipov, and V.N. Bykov: Glass Phys. Chem., 2007, vol. 33, pp. 486–91.

M. Licheron, V. Montouillout, F. Millot, and D.R. Neuville: J. Non-Cryst. Solids, 2011, vol. 357, pp. 2796–01.

Y. Wen, Q. Shu, Y. Lin, and T. Fabritius: ISIJ Int., 2023, vol. 63, pp. 1–9.

J. Li, K. Chou, and Q. Shu: ISIJ Int., 2020, vol. 60, pp. 51–57.

T.S. Kim and J.H. Park: ISIJ Int., 2014, vol. 54, pp. 2031–38.

Q. Wang, J. Yang, J. Zhang, O. Ostrovski, C. Zhang, and D. Cai: Steel Res. Int., 2021, vol. 93, p. 2100193.

L. Zhou, H. Wu, W. Wang, H. Luo, and H. Li: Ceram. Int., 2021, vol. 47, pp. 10940–49.

X. Yan, W. Pan, X. Wang, X. Zhang, and Q. Wang: Metall. Mater. Trans. B, 2021, vol. 52B, pp. 2526–35.

G.H. Kim and I. Sohn: Metall. Mater. Trans. B, 2014, vol. 45B, pp. 86–95.

G.H. Zhang, Y.L. Zhen, and K.C. Chou: J. Iron Steel Res. Int., 2016, vol. 23, pp. 633–37.

B. Lu, K. Chen, W. Wang, and B. Jiang: Metall. Mater. Trans. B, 2014, vol. 45B, pp. 1496–09.

Z. Du, S. Bao, and D. Zhang: Vacuum Electron., 2009, pp. 56-59.

S. Ding, Z. Fang, C. Wen, Y. Wu, and C. Han: China Manganese Ind., 2017, vol. 35, pp. 103–05.

Acknowledgments

The authors would like to deeply appreciate the fund support from the Natural Science Foundation of Anhui Provincial Education Department (KJ2021A0358) and the College Students Innovation and Entrepreneurship Training Program (S202210360154).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

A conflict of interest exists whenever an author has a financial or personal relationship with a third party whose interests could be positively or negatively influenced by the article's content. On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, C., Wu, T., Ren, PF. et al. Influence Mechanism of F− on the Structure and Properties of Aluminate-Based Mold Flux. Metall Mater Trans B 54, 2784–2792 (2023). https://doi.org/10.1007/s11663-023-02874-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-023-02874-6