Abstract

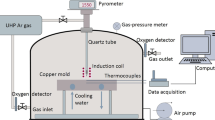

In this study, a droplet solidification technique was used to simulate the process of sub-rapid solidification and film deposition phenomenon in strip casting of boron-containing steel, and studied the effect of boron on the formation of the naturally deposited film and its corresponding interfacial heat transfer behavior. The results indicated that boron modified the surface tension of molten steel, thus increasing the interfacial wettability between the molten steel and substrate surface with the final contact angle decreasing from 102 to 89 deg, and improving the related heat transfer with maximum heat flux increasing from 6.23 to 9.11 MW/m2. The deposited film was mainly composed of elements O, Fe, Si, Mn, B, and Cr. The increasing boron content made the deposited film particles melt faster and fuse more easily. Furthermore, the deposited films of the experiments with high boron content were thicker under the same deposition times; meanwhile, with the increase of boron content, the surface roughness of the deposited film increased gradually. In addition, the interfacial heat transfer behavior was mainly related to interfacial wettability and deposited film. Also, the deposited film composed of uniformly distributed small particles was better than tiny floccule or large clusters, and the relatively good film thickness was about 3.3–4.0 μm

Similar content being viewed by others

References

M. Ueno and T. Inoue: Trans. Iron Steel Inst. Jpn., 1973, vol. 13, pp. 210–17.

G.F. Melloy, P.R. Summon, and P.P. Podgursky: Metall. Trans., 1973, vol. 4, pp. 2279–89.

S. Yin, A. Rong, and M. Tanino: J. Iron Steel Res. Int., 2013, vol. 20, pp. 99–104.

N.E. Hannerz: Trans. Iron Steel Inst. Jpn.n, 1985, vol. 25, pp. 149–58.

S. Song, A. Guo, and D. Shen: Mater. Sci. Eng. A, 2003, vol. 360, pp. 96–100.

E.L. Chipres, I. Mejia, C. Maldonado, A.B. Jacuinde, and J. Cabrera: Mater. Sci. Eng. A, 2007, vol. 460, pp. 460–64.

L.H. Chown and L.A. Cornish: Mater. Sci. Eng. A, 2008, vol. 494, pp. 263–75.

L. Karlsson: Acta Mater., 1988, vol. 36, pp. 1–2.

J.H. Lim, J.S. Kim, and B.H. Park: Korean J. Mater. Res., 2011, vol. 21, pp. 303–8.

Y. Chen, Y. Bao, M. Wang, X. Cai, L. Wang, and L. Zhao: ISIJ Int., 2014, vol. 54, pp. 2215–20.

P.G.Q. Netto, R.P. Tavares, M. Isac, and R.I.L. Guthrie: ISIJ Int., 2001, vol. 41, pp. 1340–49.

S. Xu, S. Li, S. Wang, J. Gao, R. Cao, Q. Feng, H. Li, and X. Mao: J. Iron Steel Res. Int., 2022, vol. 29, pp. 17–33.

R. An, B. Yu, R. Li, and M. Wei: Appl. Energy., 2018, vol. 226, pp. 862–80.

K.C. Mills, A.B. Fox, Z. Li, and R.P. Thackray: Ironmak. Steelmak., 2005, vol. 32, pp. 26–34.

A.R. Büchner: Steel Res. Int., 2004, vol. 75, pp. 5–12.

D.K. Choo, H.K. Moon, T. Kang, and S. Lee: Metall. Mater. Trans. A, 2001, vol. 32, pp. 2249–58.

I. Korobeinikov, D. Chebykin, S. Seetharaman, and O. Volkova: Int. J. Thermophys., 2021, vol. 42, pp. 1–2.

N. Phinichka: Doctoral Thesis, Carnegie Mellon University, 2001.

P. Nolli and A.W. Cramb: Metall. Mater. Trans. B, 2008, vol. 39, pp. 56–65.

C. Zhu, W. Wang, J. Zeng, C. Lu, L. Zhou, and J. Chang: ISIJ Int., 2019, vol. 59, pp. 880–88.

H. Xu, W. Wang, C. Lu, P. Lyu, and C. Zhu: J. Mater. Res. Technol., 2021, vol. 15, pp. 524–30.

W. Wang, D. Cai, C. Lu, P. Lyu, C. Zhu, and J. Zeng: Metall. Mater. Trans. B, 2022, vol. 53, pp. 198–07.

H.U. Lindenberg, G. Brückner, and K.H. Tacke: Steel Res. Int., 2001, vol. 72, pp. 490–95.

S. Ge, M. Isac, and R.I.L. Guthrie: ISIJ Int., 2012, vol. 52, pp. 2109–22.

W. Dou, G. Yuan, M. Lan, Y. Zhang, and M. Zhou: Steel Res. Int., 2020, vol. 91, p. 15.

M. Daamen, O. Güvenç, M. Bambach, and G. Hirt: CIRP Ann-Manuf. Techn., 2014, vol. 63, pp. 265–68.

C. Zhu, J. Zeng, and W. Wang: Sci. China Technol. Sci., 2022, vol. 5, pp. 493–18.

C. Zhu, W. Wang, and C. Lu: J. Alloys Compd., 2019, vol. 770, pp. 631–39.

W. Wang, C. Zhu, J. Zeng, C. Lu, P. Lyu, H. Qian, and H. Xu: Metall. Mater. Trans. B, 2020, vol. 51, pp. 45–53.

W. Wang, C. Zhu, C. Lu, J. Yu, and L. Zhou: Metall. Mater. Trans. A, 2018, vol. 49, pp. 5524–34.

W. Wang, C. Zhu, J. Zeng, C. Lu, H. Qian, H. Xu, and P. Lyu: Metall. Mater. Trans. A, 2020, vol. 51, pp. 2306–17.

C. Zhu, W. Wang, and C. Lu: J. Sustain. Metall., 2019, vol. 5, pp. 378–90.

Acknowledgments

The financial support from the National Natural Science Foundation of China (52204356, 52274342, 52130408), National Science Fund for Overseas Excellent Young Scholars (21FAA01748), and Hunan Scientific Technology Projects (2019RS3007, 2020WK2003) is greatly acknowledged.

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, W., Hao, L., Lu, C. et al. Effect of Boron on the Formation of the Naturally Deposited Film and Its Corresponding Interfacial Heat Transfer Behavior in Strip Casting of Boron-Containing Steel. Metall Mater Trans B 54, 2712–2722 (2023). https://doi.org/10.1007/s11663-023-02868-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-023-02868-4