Abstract

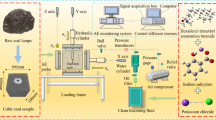

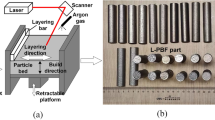

The lateral injection of air and pulverised coal in the lower regions of a blast furnace is experimentally represented by the lateral inlet of gas–powder through a tuyere which, protrudes into a rectangular packed bed featuring fixed, impermeable blocks to represent the fused iron layers of the cohesive zone observed in blast furnaces. The raceway characteristics of the slowly descending burden in actual blast furnaces was replicated in a fixed-bottom bed by performing the experiments under the decreasing gas velocity condition and choosing experimental parameters that ensure similarity criteria between the experiments and real-blast furnace are satisfied. Experiments are carried out in the presence of a raceway, at the various gas flow rate, powder size and flux, packing particle size, and packing particle/powder density under decreasing gas–powder flow conditions to estimate the static and dynamic powder holdup using the procedure presented by Gupta et al. (Trans Indian Inst Metals 64:1–5, 2021). It was found that the powder accumulates predominantly in the corner opposite to the inlet and above some of the cohesive layers. An exploratory data analysis is performed to determine the rate of static holdup growth/decay under various operating conditions. The experimental data is also used to develop a correlation for static and dynamic powder holdup which, resulted in a 95 pct confidence interval.

Graphical Abstract

Similar content being viewed by others

Abbreviations

- \(\epsilon \) :

-

Void fraction occupied by the gas phase (–)

- \(\rho _g\) :

-

Density of the gas phase (kg/m3)

- \(\rho _p\) :

-

Density of packed particles (kg/m3)

- \(\rho _f\) :

-

Density of the fines phase (kg/m3)

- \(\overrightarrow{V_g}= U_g \hat{i} + V_g \hat{j}\) :

-

Superficial velocity of the gas phase (m/s)

- p :

-

Pressure (Pa)

- \(\overrightarrow{V_f}= U_f \hat{i}+V_f \hat{j}\) :

-

Superficial velocity of the fines phase (m/s)

- \(\mu _f\) :

-

Viscosity of the fines phase (obtained through rheological studies) (Ns/m2)

- \(\mu _g\) :

-

Viscosity of the gas phase (Ns/m2)

- \(\phi _p\) :

-

Shape factor of the packed bed particles (–)

- \(\phi _f\) :

-

Shape factor of the fines particles (–)

- \(d_p\) :

-

Diameter of packed particles (m)

- \(d_f\) :

-

Diameter of fines particles (m)

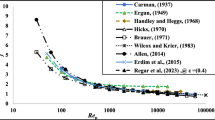

- \(Re_p = \frac{\rho _p \phi _p d_p |\overrightarrow{V_g}|}{\mu _g}\) :

-

Reynolds number for the packed bed particles (–)

- \(Fr = \frac{|\overrightarrow{V_f}|}{\sqrt{g d_f}}\) :

-

Froude number (–)

- \(G_f\) :

-

Feed rate of the fines phase through the tuyere (kg/m2s)

- \(H_s\) :

-

Static holdup of fines (kg)

- \(H_d\) :

-

Dynamic holdup of fines (kg)

- \(V_{in}\) :

-

In flow velocity of the gas phase (m/s)

References

G.S. Gupta, S. Lakshminarasimha, and M. Shrenik: Trans. Indian Inst. Metals, 2021, vol. 64, pp. 1–5.

J.-P. Birat, J.-P. Vizioz, Y. De Lassat, M. de Pressigny, and M.J. Schneider: Revue de Metallurgie, 1999, vol. 96, pp. 1203–16.

Y. Takamoto, K. Yamaguchi, H. Ueno, S. Matsunaga, K. Kakiuchi, and S. Amano: Revue de Métallurgie, 1995, vol. 92, pp. 351–60.

A. Babich: Ironmak. Steelmaking, 2021, vol. 48, pp. 1–14.

K. Yamaguchi, H. Ueno, S. Matsunaga, K. Kakiuchi, and S. Amano: ISIJ Int., 1995, vol. 35, pp. 148–55.

J. O’Hanlon: Steel Times, 1993, vol. 221, p. 508.

A. Maki, A. Sakai, N. Takagaki, K. Mori, T. Ariyama, M. Sato, and R. Murai: ISIJ Int., 1996, vol. 36, pp. 650–57.

R. J. Fruehan, AISE Steel Foundation, 1998.

K. Wu, W. Pan, W. Xu, X. Yin, J. Zhang, and W. Wu: Steel Res. Int., 2008, vol. 79, pp. 904–07.

M. Deguchi, K. Shibata, J. Fukuoka, CAMP-ISIJ, 1988.

Y. Matsui, T. Maki, R. Ono, T. Goto, R. Hori, T. Kukihara, CAMP-ISIJ, 1990.

K. Tamura, H. Ueno, K. Yamaguchi, M. Sugata, S. Amano, and K. Yamaguchi: Tetsu-to-Hagané, 1991, vol. 77, pp. 775–82.

K. Yamaguchi and T. Uno: Tetsu-to-Hagané, 1999, vol. 85, pp. 578–84.

Y. Omori, Committee on reaction within blast furnace, 1987.

K. Kanbara, T. Hagiwara, A. Shigemi, S.-I. Kondo, Y. Kanayama, K.-I. Wakabayashi, and N. Hiramoto: Tetsu-to-Hagané, 1976, vol. 62, pp. 535–46.

Y. Shimomura, K. Nishikawa, S. Arino, T. Katayama, Y. Hida, and T. Isoyama: Tetsu-to-Hagané, 1976, vol. 62, pp. 547–58.

K. Sasaki, M. Hatano, M. Watanabe, T. Shimoda, K. Yokotani, T. Ito, and T. Yokoi: Tetsu-to-Hagane, 1976, vol. 62, pp. 580–91.

J. Chen, T. Akiyama, H. Nogami, and J.-I. Yagi: ISIJ Int., 1994, vol. 34, pp. 133–39.

S. Kamble, S. Lakshminarasimha, A. Maurya, and G.S. Gupta: Trans. Indian Inst. Met., 2020, vol. 73, pp. 2081–87.

S. Kamble, F.S.D. Bosco, and G.S. Gupta: Metall. Mater. Trans. B, 2022, vol. 53B, pp. 1–15.

S. Rajneesh and G.S. Gupta: Powder Technol., 2003, vol. 134, pp. 72–85.

S. Sarkar, G.S. Gupta, J. Litster, V. Rudolph, E. White, and S. Choudhary: Metall. Mater. Trans. B, 2003, vol. 34B, pp. 183–91.

V. Mojamdar, G.S. Gupta, and A. Puthukkudi: ISIJ Int., 2018, vol. 58, pp. 1396–401.

X. Dong, D. Pinson, S. Zhang, A. Yu, and P. Zulli: Powder Technol., 2004, vol. 149, pp. 1–9.

S. Li, Y. Ding, and Y. He: Chem. Eng. Sci., 2006, vol. 61, pp. 1922–31.

V. Gunjal, M. Lollchund, and G.S. Gupta: Int. J. Eng. Syst. Modell. Simul., 2010, vol. 2, pp. 204–10.

F.S.D. Bosco, S. Kamble, S. Lakshminarasimha, and G.S. Gupta: Ironmak. Steelmak., 2023, https://doi.org/10.1080/03019233.2023.2212214.

K. Shibata, M. Shimizu, S.-I. Inaba, R. Takahashi, and J.-I. Yagi: ISIJ Int., 1991, vol. 31, pp. 434–39.

Y. Ding, Z. Wang, D. Wen, and M. Ghadiri: Powder Technol., 2005, vol. 153, pp. 13–22.

N. Hidaka, J. Iyama, T. Matsumoto, K. Kusakabe, and S. Morooka: Powder Technol., 1998, vol. 95, pp. 265–71.

N. Hidaka, T. Matsumoto, K. Kusakabe, and S. Morooka: J. Chem. Eng. Jpn., 2000, vol. 33, pp. 152–59.

Z. Wang, Y. Ding, and M. Ghadiri: Chem. Eng. Sci., 2004, vol. 59, pp. 3071–79.

H. Takahashi, H. Kawai, T. Kondo, and M. Sugawara: ISIJ Int., 2011, vol. 51, pp. 1608–16.

B. Panic, L. Krol, and J. Dankmeyer-Laczny: Steel Res., 2000, vol. 71, pp. 271–76.

X. Dong, S. Zhang, D. Pinson, A. Yu, and P. Zulli: Powder Technol., 2004, vol. 149, pp. 10–22.

S. Sarkar, G.S. Gupta, and S.-Y. Kitamura: ISIJ Int., 2007, vol. 47, pp. 1738–44.

T. Pham, PhD thesis, University of New South Wales, 2001.

S. Lakshminarasimha, A. Maurya, G.S. Gupta, and G.V. Arun Chaitanya: Can. J. Chem. Eng., 2023, vol. 101, pp. 883–95.

Acknowledgments

We wish to thank Mr. Ansuman Dash for the numerous discussions and also greatly acknowledge the financial support provided by the Department of Science and Technology (DST), New Delhi, India (Grant Nos. SB/53/ME/027/2014 and CRG/2019/000292) and Council of Scientific and Industrial Research (CSIR), India.

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose. The authors have no competing interests to declare that are relevant to the content of this article. All authors certify that they have no affiliations with or involvement in any organization or entity with any financial interest or non-financial interest in the subject matter or materials discussed in this manuscript. The authors have no financial or proprietary interests in any material discussed in this article.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lakshminarasimha, S., Bosco, F.S.D., Gadi, V.A. et al. Quantitative Measurement and Analysis of Powder Holdups in a Packed Bed in the Presence of Internal Blocks and Raceway. Metall Mater Trans B 54, 2694–2711 (2023). https://doi.org/10.1007/s11663-023-02867-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-023-02867-5