Abstract

This study presents a new approach for RH degasser for desulfurization purposes. The modified RH has a short down leg length, so the steel flowing through this leg is discharged above the slag–metal interface. Physical and mathematical modeling were carried out and the results show that a large slag dispersion into steel can be achieved, so an efficient desulfurization is expected for this modified reactor. In the physical model as well as in computational fluid dynamics simulations, water or a saline solution were used to mimic the steel similar phase and three kinds of oils to emulate the slag. It was observed that as circulation rate is increased, the emulsification increased too. Additionally, for large phase density difference it was observed that oil dispersion is already intense, but it is concentrated nearby the down leg flow. CFD simulations were applied to RH industrial unit too, and as expected, a large slag entrainment into steel is observed and sustained. The dispersed phase flows nearby the steel jet coming from down leg. Furthermore, this modification on RH does not compromise the main RH functions since no change on circulation rates and mixing times was observed.

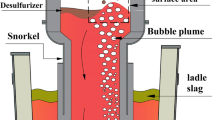

Adapted from Ref. [2]

Similar content being viewed by others

Abbreviations

- dp:

-

Droplet diameter (m)

- g :

-

Acceleration of gravity (m/s2)

- G :

-

Gas flow rate (STP L/min)

- Q :

-

Circulation rate (kg/s)

- [S]:

-

Steel sulfur concentration (ppm)

- \(v\) :

-

Volume (m3 or L)

- V :

-

Velocity (m/s)

- t :

-

Time (s)

- L S :

-

Slag–metal sulfur partition coefficient

- E :

-

Specific rate of input of kinetic energy (W/t)

- C t :

-

Instantaneous concentration (kg/m3)

- C ∞ :

-

Final concentration (kg/m3)

- ρ :

-

Density (kg/m3)

- μ :

-

Dynamic viscosity (Pa·s)

- τ mix . :

-

Mixing time (s)

- ε :

-

Average rate of dissipation of kinetic energy of turbulence (m2/s3)

- κ :

-

Kinetic energy of turbulence (m2/s2)

- σ :

-

Interfacial tension (N/m)

- \(\alpha_{i}\) :

-

Volume fractions of each phase

- g :

-

Gaseous phase

- l :

-

Liquid phase

- o :

-

Oil

- ss:

-

Saline solution

- w :

-

Water

References

F.N.H. Schrama, E.M. Beunder, B. van den Berg, Y. Yang, and R. Boom: Ironmak. Steelmak., 2017, vol. 44, pp. 333–43.

A.M.B. Silva, M.A. Oliveira, J.J.M. Peixoto, and C.A. da Silva: Metall. Mater. Trans. B, 2021, vol. 52B, pp. 2111–26.

A.M.B. Silva, J.J.M. Peixoto, C.A. da Silva, and I.A. da Silva: REM Int. Eng. J., 2022, vol. 75(1), pp. 27–35.

J.H. Wei, S.J. Zhu, and N.W. Yu: Ironmak. Steelmak., 2000, vol. 27, pp. 129–37.

Z. Zulhan, Y.A. Patriona, and C. Schrade: SEAISI Q. J., 2013, vol. 42(4), pp. 32–36.

W.V. Bielefeldt, PhD thesis, Federal University of Rio Grande do Sul/UFRGS, Porto Alegre, 2009.

A. Ghosh: Secondary Steelmaking: Principles and Applications, CRC Press LLC, New York, 2001, pp. 181–217.

P.C. Pistorius and M.K.G. Vermaak: S. Afr. J. Sci., 1999, vol. 95, pp. 377–80.

P. Riboud and R. Vasse: Rev. Metall., 1985, vol. 82, pp. 801–10.

C. Schrade, H. Nicolai, and Z. Zulhan: METEC, 2015, vol. 2, pp. 1–5.

J.J.M. Peixoto, W.V. Gabriel, T.S. De Oliveira, C.A. da Silva, I.A. da Silva, and V. Seshadri: Metall. Mater. Trans. B, 2018, vol. 49B, pp. 2421–34.

J. Szekely, G. Carlsson, and L. Helle: Ladle Metallurgy, Springer, New York, 1989, pp. 8–22.

H. Yang, S. Yang, J. Li, and J. Zhang: J. Iron. Steel Res. Int., 2014, vol. 21, pp. 995–1001.

W.X. Dai, G.G. Cheng, G.L. Zhang, Z.D. Huo, Y.L. Qiu, and W.F. Zhu: Metall. Mater. Trans. B, 2020, vol. 51B, pp. 611–27.

H. Yang, J. Li, Z. Gao, F. Song, and W. Yang: Mater. Process. Fundam., 2013, pp. 45–52.

P.S.B. Lascosqui: master’s Thesis, Federal University of Ouro Preto/UFOP, Ouro Preto, MG, Brazil, 2006.

M.B. Campos, J.J.M. Peixoto, C.A. da Silva, and I.A. Silva: REM Int. Eng. J., 2020, vol. 73(3), pp. 353–59.

K. Shirabe and J. Szekely: Trans. Iron Steel Inst. Jpn., 1983, vol. 23, pp. 465–74.

Y. Miki, B.G. Thomas, A. Denissov, and Y. Shimada: Steelmak. Conf. Proc., 1997, vol. 24(8), pp. 31–38.

W. Yang, X. Wang, L. Zhang, Q. Shan, and X. Liu: Steel Res. Int., 2013, vol. 84(5), pp. 473–89.

M. Wang, J. Guo, X. Li, C. Yao, and Y. Bao: Vacuum, 2021, vol. 185, pp. 1–9.

G. Lee and K. Bertermann: 79th Steelmaking Conf. Proc., Pittsburgh, PA, 1996, vol. 79, pp. 61–65.

W. Bading, C. Lindner, E. Julius, and H. Haubrich: 78th Steelmaking Conf. Proc., Nashville, TN, 1995, vol. 78, pp. 237–41.

S.G.P.T de Abreu, T.A.S. de Oliveira, J.V.G. G. Ananias, G.S. Queiroz, I.A. da Silva, C.A. da Silva and J.J.M. Peixoto: 50th Seminário de Aciaria, Fundiçãoe Metalurgia de Não-Ferrosos, São Paulo SP, 2019, vol. 50, pp. 638–48.

W.V. Gabriel: PhD thesis, Federal University of Ouro Preto/UFOP, Ouro Preto, MG, Brazil, 2020.

K. Yamaguchi, T. Sakuraya, and K. Hamagami: Kawasaki Steel Tech. Rep., 1995, vol. 32, pp. 33–37.

F. Ahrenhold and W. Pluschkell: Steel Res., 1998, vol. 69(2), pp. 54–59.

X.F. Wang, F.P. Tang, Y. Lin, and C.J. Wu: Ironmak. Steelmak., 2014, vol. 41(9), pp. 694–98.

S.K. Ajmani, S.K. Dash, S. Chandra, and C. Bhanu: ISIJ Int., 2004, vol. 44, pp. 82–90.

Y.G. Park, W.C. Doo, K.W. Yi, and S.B. An: ISIJ Int., 2000, vol. 40, pp. 749–55.

S.P. He, G.J. Chen, and C.J. Guo: Ironmak. Steelmak., 2019, vol. 46, pp. 771–76.

Ansys Inc.: ANSYS CFX- Solver Theory Guide, Release 18.2, Canonsburg, PA, 2017, pp. 153–269.

L.F. Zhang and F. Li: JOM, 2014, vol. 66, pp. 1227–40.

K. Zhang, H. Cui, R. Wang, and Y. Liu: Met., 2019, vol. 9, pp. 1–12.

J. Pieprzyca, T. Merder, M. Saternus, and K. Michalek: Arch. Metall. Mater., 2015, vol. 60(3A), pp. 1859–63.

K. Yoshitomi, M. Nagase, M.A. Uddin, and Y. Kato: ISIJ Int., 2016, vol. 56, pp. 1119–23.

J.H. Wei, N.M. Yu, Y.Y. Fan, S.L. Yang, J.C. Ma, and D.P. Zhu: J. Shanghai Univ., 2002, vol. 6(2), pp. 167–75.

B. Zhu, Q. Liu, D. Zhao, S. Ren, M. Xu, B. Yang, and B. Hu: Steel Res. Int., 2016, vol. 87(2), pp. 136–45.

M.I.I.Z. Abidin, A.A.A. Raman, and M.I.M. Nor: Ind. Eng. Chem. Res., 2014, vol. 53(15), pp. 6554–61.

M. Song, Q. Shu, and D. Sichen: Steel Res. Int., 2011, vol. 82, pp. 260–68.

T.C. Silva, E.F. Rodrigues, C.Soares, C.A. Silva, and I.A. Silva: Proc. 46th Seminário Internacional de Aciaria, ABM, Rio de Janeiro, 2015, pp. 194–204.

P. Sulasalmi, V.V. Visuri, and T. Fabritius: Mater. Sci. Forum, 2013, vol. 762, pp. 242–47.

P. Sulasalmi, V.V. Visuri, A. Kärnä, and T. Fabritius: Steel Res. Int., 2015, vol. 85, pp. 212–22.

Nippon Slag Association, https://www.slg.jp/e/slag/process.html. Accessed 28 Oct 2020.

R.J. Fruehan: The Making, Shaping and Treating of Steel, 11th edn., Steelmaking and Refining Volume, AISE, Pittsburgh, PA, 1998, pp. 664–65.

C.A da Silva, I.A Silva, L.F.A de Castro LFA, R.P. Tavares, V. Seshadri: Termodinâmica Metalúrgica: balanços de energia, soluções e equilíbrio químico em sistemas metalúrgicos, Blucher—ABM, São Paulo, SP, 2018, pp. 83-139.

A.E. Morris, G. Geiger, and H.A. Fine: Handbook on Material and Energy Balance Calculations in Material Processing, Wiley, New York, 2012, pp. 1–2666.

N. El-Kaddah and J. Szekely: Ironmak. Steelmak., 1981, vol. 8, pp. 269–78.

B. Deo and R. Boom: Fundamentals of Steelmaking Metallurgy, Prentice Hall International, London, 1993, pp. 254–61.

Acknowledgments

The authors acknowledge the help provided by UFOP, IFMG, CNPq, CAPES, and FAPEMIG.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Silva, A.M.B., Peixoto, J.J.M. & da Silva, C.A. Numerical and Physical Modeling of Steel Desulfurization on a Modified RH Degasser. Metall Mater Trans B 54, 2651–2669 (2023). https://doi.org/10.1007/s11663-023-02864-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-023-02864-8