Abstract

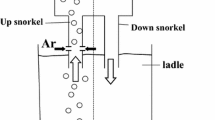

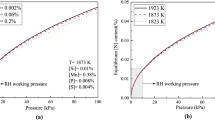

The bubble motion behavior and the inclusion removal during the argon injection processing through the down leg of an Ruhrstahl–Heraeus (RH) unit have been investigated using physical modelling, numerical simulating, and theoretical calculations. From the results obtained, it was found that the micro-bubbles generated by argon injection through the down leg can be sent to the ladle below by the downward liquid steel. Increasing the up-leg argon flow rate and decreasing the down-leg argon flow rate as well as the gas nozzle size are beneficial to produce small and dispersed bubbles. Increasing the down-leg argon flow rate would favor an increase of bubble number density. When the up-leg volume argon flow rate is 161 m3/h, the bubbles experience a longer exposure in the vertical direction: for the conditions of the argon nozzle diameter ranging from 0.2 to 0.8 mm and the down-leg argon flow rate from 120 to 1200 mL/min, the largest sinking depth of the bubbles can be controlled to surpass 2.44 m—that is, the lowermost bubbles are close to the bottom of the ladle. The largest spreading length of the bubbles in the horizontal direction is from 0.93 to 2.03 m under all the conditions, corresponding to 32 to 71 pct of the ladle diameter. The down-leg has a large space to set many argon nozzles. Increasing the total down-leg flow rate by the layout of adding the number of the argon nozzles can significantly improve the bubble dispersion and number density. Using the argon injection through down-leg technique can remove nearly all the 50 μm diameters inclusions. The removal efficiency of the inclusions with diameter of 20 μm reaches 55 pct. For the 10 μm diameters inclusions, the removal efficiency is over 10 pct.

Similar content being viewed by others

References

S. Chang, Z. Zou, J. Liu, M. Isac, X. Cao, X. Su, and R.I.L. Guthrie: Powder Technol., 2021, vol. 387, pp. 125–35.

X. Wang, F. Tang, W. Yao, and Y. Lin: Ironmak. Steekmak., 2019, vol. 46, pp. 906–10.

K. Li, J. Liu, J. Zhang, and S. Shen: Metall. Mater. Trans. B, 2017, vol. 48B, pp. 2136–46.

J. Liu, W. Li, Y. He, X. Su, J. Zhang, and F. Chang: Chin. J. Eng., 2021, vol. 44, pp. 1183–91.

S. Zhang, J. Liu, Y. He, C. Zhou, B. Yuan, and A. Mclean: J. Mater. Process. Technol., 2022, vol. 306, p. 117647.

J. Park, S. Kang, and J. Park: Metall. Res. Technol., 2008, vol. 105, pp. 424–27.

K.L. Sutherland: J. Phys. Chem., 1948, vol. 52, p. 394.

M.E. Weber and D. Paddock: J. Colloid Interface Sci., 1983, vol. 94, pp. 328–35.

H.J. Schulze: Miner. Process. Extr. Metall. Rev., 1989, vol. 5, pp. 43–76.

R.H. Yoon and G.H. Luttrell: Miner. Process. Extr. Metall. Rev., 1989, vol. 5, pp. 101–22.

A.V. Nguyen, H.J. Schulze, and J. Ralston: Int. J. Miner. Process., 1997, vol. 51, pp. 183–95.

L. Wang, H.G. Lee, and P. Hayes: ISIJ Int., 1996, vol. 36, pp. 7–16.

L. Zhang and S. Taniguchi: Int. Mater. Rev., 2000, vol. 45, pp. 59–82.

P.T.L. Koh and M.P. Schwarz: Miner. Eng., 2006, vol. 19, pp. 619–26.

H. Darabi, S.M.J. Koleini, D. Deglon, B. Rezai, and M. Abdollahy: Powder Technol., 2020, vol. 375, pp. 109–23.

J.P. Rogler, L.J. Heaslip, and M. Mehrvar: Can. Metall. Q., 2004, vol. 43, pp. 407–15.

L. Zhang, J. Aoki, and B.G. Thomas: Metall. Mater. Trans. B, 2006, vol. 37B, pp. 361–79.

S. Chang, L. Zhong, and Z. Zou: ISIJ Int., 2015, vol. 55, pp. 837–44.

Y. Wang, Q. Fang, H. Zhang, J. Zhou, C. Liu, and H. Ni: Metall. Mater. Trans. B, 2020, vol. 51B, pp. 1088–1100.

G. Chen, S. He, and Y. Li: Metall. Mater. Trans. B, 2017, vol. 48B, pp. 2176–86.

Y. Sun, X. Cao, F. Liang, and J. Bian: Process. Saf. Environ., 2020, vol. 136, pp. 268–79.

H. Ling and L. Zhang: Metall. Mater. Trans. B, 2018, vol. 49B, pp. 2709–21.

B. Wang, B. Zhu, and B. Zhang: JOM-US, 2021, vol. 73, pp. 2920–28.

G. Chen and S. He: J. Mater. Res. Technol., 2020, vol. 9, pp. 3318–29.

R.S. Amano, B. Song, and M.S. Reza: in ASME Turbo Expo, Nevada, USA, 2005.

A. Schmidt, V. Montenegro, M. Reuter, A. Charitos, M. Stelter, and A. Richter: Metall. Mater. Trans. B, 2022, vol. 53B, pp. 3765–74.

B. Zhu, Q. Liu, M. Kong, J. Yang, D. Li, and K. Chattopadhyay: Metall. Mater. Trans. B, 2017, vol. 48B, pp. 2620–30.

H. Ling and L. Zhang: Metall. Mater. Trans. B, 2019, vol. 50B, pp. 2017–28.

Y. Xu, M. Liu, and C. Tang: Chem. Eng. J., 2013, vol. 222, pp. 292–306.

S. Chang, W. Huang, Z. Zou, B. Li, and R.I.L. Guthrie: Powder Technol., 2020, vol. 367, pp. 296–304.

R. Wang, Y. Jin, and H. Cui: Metall. Mater. Trans. B, 2022, vol. 53B, pp. 342–51.

H. Tanaka, R. Tsujino, A. Imamura, R. Nishihara, and J. Konishi: ISIJ Int., 1994, vol. 34, pp. 498–506.

Acknowledgments

The authors are grateful for support from the National Natural Science Foundation of China (Grant No. 52174292).

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, S., Liu, J., He, Y. et al. Study of Dispersed Micro-bubbles and Improved Inclusion Removal in Ruhrstahl–Heraeus (RH) Refining With Argon Injection Through Down Leg. Metall Mater Trans B 54, 2347–2359 (2023). https://doi.org/10.1007/s11663-023-02836-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-023-02836-y