Abstract

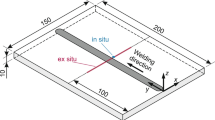

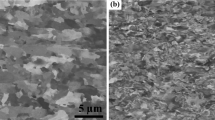

The choice of weld parameters determines the size, shape, and curvature of grains in the fusion zone (FZ) and heat-affected zone (HAZ) of welds while the mechanical properties of the welds are correlated to this microstructure. A new technique to quantitatively evaluate these microstructural characteristics in both zones of welds has been applied to molybdenum gas tungsten arc welds fabricated using different weld parameters. Trends in microstructural characteristics in the FZ and HAZ were evaluated and correlated with changes to heat input, weld speed, and weld technique. The use of this approach showed that a 20 pct decrease in heat input caused a 20 pct decrease in the number of FZ grains with aspect ratios ≥ 4. The orientations of the FZ grain segments as a function of distance from the FZ centerline were significantly affected by the weld speed and its effect on weld pool shape. A 50 pct increase in weld speed caused a 20 pct decrease in grain segments orientated 60 to 90 deg from the normal to the direction of welding. This technique also captured differences in grain sizes and grain size anisotropy in the FZ between welds made with a constant current, pulsed current, and use of a 4-pole-magnetic oscillator.

Similar content being viewed by others

References

T. Senda, F. Matsuda, M. Kato, and H. Nakagawa: AWS, 1969, vol. 38(12), pp. 1379–84.

H. Wei, J. Elmer, and T. Debroy: Acta Mater., 2017, vol. 126, pp. 413–25.

S. David, R. Miller, and Z. Feng: Sci. Technol. Weld. Join., 2016, vol. 22(3), pp. 244–56.

T. Debroy and S. David: Rev. Mod. Phys., 1995, vol. 67(1), pp. 85–112.

Z. Wu, A. Davidi, D. N. Leonard, Z. Feng and H. Bei: Sci. Technol. Weld. Join., 2018, pp. 1–11.

Y. Yehorov, L.J. Silva, and A. Scotti: Int. J. Adv. Manuf. Technol., 2019, vol. 104, pp. 1581–92.

T.J. Balk, K.J. Hemker, and L.P. Kubin: Scripta Mater., 2007, vol. 56, pp. 389–92.

S. Kou and Y. Le: Weld. Res. Suppl., 1986, vol. 65, pp. 305–13.

S.A. David, S. Babu, and J. Vitek: JOM, 2003, vol. 55, pp. 14–20.

W. Tan and Y. Shin: Comput. Mater. Sci., 2015, vol. 98, pp. 446–58.

S. Kou and Y. Le: Metall. Mater. Trans A., 1988, vol. 19A, pp. 1075–82.

S. Chen, G. Guillemot, and C.-A. Gardin: ISIJ, 2014, vol. 54, pp. 401–07.

M. Hashemi and A. Halvaee: Trans. Indian Inst. Met., 2014, vol. 67, pp. 741–52.

M. Cheepu, D. Venkateswarlu, P.M. Rao, S.S. Kumaran, and N. Srinvasan: Mater. Sci. Forum, 2019, vol. 969(1662–9752), pp. 895–900.

A. Stine, S. Pierce and P. Moniz: LANL, 2015.

D. W. Becker and J. C.M. Adams: Weld. Res. Suppl., 1979, pp. 143–52.

G. Sorner, T. Sarikka, P. Vilaca, and T.G. Santos: Weld. World, 2018, vol. 62, pp. 1173–85.

Y. Li, H. Yan, J. Chen, W. Xia, B. Su, T. Ding, and X. Li: Mater. Res. Express., 2020, vol. 7, p. 076506.

T. Rodgers, J. Madison, V. Tikare, and M. Maguire: JOM, 2016, vol. 68, pp. 1419–26.

J. Devletion and W. Wood: Met. Handbook, 1983, vol. 6, pp. 22–49.

J. V. S. David: Int. Trend. Sci. Technol. Weld, 1993, pp. 147–57.

D. Min, J. Shen, S. Lai, and J. Chen: Mater. Charact., 2009, vol. 60, pp. 1583–90.

H. Saedi and W. Unkel: Weld. Res. Supp., 1988, vol. 64, pp. 247–55.

R. Manti, D. Dwivedi, and A. Agarwal: Adv. Manuf. Technol., 2008, vol. 36, pp. 263–69.

N.K. Babu, S.G.S. Raman, R. Mythili, and S. Saroja: Mater. Charact., 2007, vol. 58, pp. 581–87.

S. Mahajan, N. Biradar, R. Raman, and S. Mishra: Trans. Indian Inst. Met. T, 2012, vol. 65(2), pp. 171–77.

Y. Lim, X. Yu, J. Cho, D. Farson, S. Babu, S. McCracken, and B. Flesner: Sci. Technol. Weld. Join., 2010, vol. 15(7), pp. 583–89.

Y. Sharir, J. Pelleg, and A. Grill: Met. Technol., 1978, vol. 5(1), pp. 190–96.

T. R. Larquer and R. P. Reis: in Joining Technologies, 2016, IntechOpen.

N. Kohlhorst, G. Muralidharan, R. Miller, and J. Zhao: Scripta Mater., 2020, vol. 182, pp. 62–67.

Weighted arithmetic mean, Wikipedia , 2021.

T. Rodgers, J.A. Mitchell, and V. Tikare: Model. Simul. Mater. Sci. Eng., 2017, vol. 25, p. 064006.

Acknowledgments

This manuscript has been authored by UT-Battelle, LLC under Contract No. DE-AC05-00OR22725 with the U.S. Department of Energy. The authors would like to acknowledge Alan Frederick, Doug Kyle for welding trials, Caitlin Duggan, Victoria Cox, and Tom Geer for metallography, Kevin Hanson and Ian Stinson for material processing and heat treatments. The authors would also like to acknowledge Glenn Romanoski, Yong Chae Lim, and Dean Pierce for their review of the manuscript. This work was funded by the National Aeronautics and Space Administration in partnership with the U.S. Department of Energy. The United States Government retains, and the publisher, by accepting the article for publication, acknowledges that the United States Government retains a non-exclusive, paid-up, irrevocable, world-wide license to publish or reproduce the published form of this manuscript, or allow others to do so, for United States Government purposes. The Department of Energy will provide public access to these results of federally sponsored research in accordance with the DOE Public Access Plan (http://energy.gov/downloads/doe-public-access-plan).

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kohlhorst, N.M., Faraone, K.M., Miller, R.G. et al. A Technique for the Quantitative Characterization of Weld Microstructure and Application to Mo Welds. Metall Mater Trans B 54, 1434–1448 (2023). https://doi.org/10.1007/s11663-023-02771-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-023-02771-y