Abstract

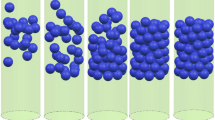

Venturi jet pyrolysis is a popular method for the preparation of micro–nanocerium oxide. Its atomization performance should be investigated because it influences the purity and particle size of cerium oxide. This was carried out in this study via a combination of experiments and fluent simulation. Images obtained from physical experiments revealed the effect of jet atomization and the variation rule of the average Sauter diameter. Numerical simulation of the jet atomization process was carried out using the VOF-to-DPM model, SST turbulence model, KH-RT droplet crushing model, and random collision model. The initial atomization time of jet atomization decreased with increase in gas velocity, and at varying solution velocities, the initial atomization time of jet atomization varied slightly. Particle uniformity of the Venturi reactor was the best at throat velocities of 35 and 90 m/s at low and high gas velocities, respectively. At varying values of inlet velocities of the solution, the optimum preparation condition was 0.01 m/s and a fine and consistent particle diameter. The findings of this study provide helpful insights for further improving and optimizing the Venturi pyrolysis reactor.

Similar content being viewed by others

Data Availability

We state that all data included in this study are available upon request by contact with the corresponding author.

Change history

14 June 2023

A Correction to this paper has been published: https://doi.org/10.1007/s11663-023-02831-3

References

C. Silvia, P. Meritxell, C. Gregori, O. Denise, R. Jordi, M.R. Manuel, C. Eudald, C. Pedro, M.L. Pedro, F.V. Guillermo, C. Pedro, P. Victor, and J. Wladimiro: Int. J. Mol. Sci., 2019, vol. 20(23), pp. 5959–65.

V.D. Kosynkin, A.A. Arzgatkin, E.N. Ivanov, M.G. Chtouts, A.I. Grabko, and A.V. Kardapolov: J. Alloys Compd., 2000, vol. 303, pp. 421–25.

X.F. Zhang, R.T. Guo, J.L. Wu, and W.G. Pan: J. Eng. Themal Energy Power, 2022, vol. 37(02), pp. 92–99.

W.C. Chueh, Y. Hao, and W.C. Jung: Nat. Mater., 2012, vol. 11(2), pp. 155–61.

C. Lv, M.H. Sun, H.X. Yin, Z.F. Wang, and T.Y. Xia: Crystals, 2021, vol. 11(8), pp. 912–22.

C. Lv, T.A. Zhang, Z.H. Dou, and Q.Y. Zhao: Rare Met., 2019, vol. 38(12), pp. 1160–68.

Q. Li, D.Z. Ming, M. Lei, X. Guo, J.L. Liu, H.W. Zhu, L. Fang, and Z.B. Wang: Eng. Appl. Comput. Fluid Mech., 2022, vol. 16(1), pp. 229–47.

A. Mosavi, S. Shamshirband, E. Salwana, K.W. Chau, and J.H.M. Tah: Eng. Appl. Comput. Fluid Mech., 2019, vol. 13(1), pp. 482–92.

S. Shamshirband, M. Babanezhad, A. Mosavi, N. Nabipour, E. Hajnal, L. Nadai, and K.-W. Chau: Eng. Appl. Comput. Fluid Mech., 2020, vol. 14(1), pp. 367–78.

K. Sakamatapan, M. Mesgarpour, O. Mahian, H.S. Ahn, and S. Wongwises: Case Stud. Therm. Eng., 2021, vol. 27, p. 101238.

C.H. Lee, H. Choi, D.W. Jerng, D.E. Kim, S. Wongwises, and H.S. Ahn: Int. J. Heat Mass Transf., 2019, vol. 136, pp. 1127–38.

A. Kolmogorov: Dokl. Akad. Navk. SSSR, 1949, vol. 66, pp. 825–28.

C.A. Coulaloglou and L.L. Tavlarides: Chem. Eng. Sci., 1977, vol. 32(11), pp. 1289–97.

H.P. Grace: Chem. Eng. Commun., 1982, vol. 14(3–6), pp. 225–77.

X.Y. Fu and M. Ishii: Nucl. Eng. Des., 2003, vol. 219(2), pp. 143–68.

T. Wang, J. Wang, and J. Yong: Chem. Eng. Sci., 2005, vol. 60(22), pp. 6199–209.

C. Hirt and B. Nichols: J. Comput. Phys., 1981, vol. 39, pp. 201–25.

S. Osher and J.A. Sethian: J. Comput. Phys., 1988, vol. 79, pp. 12–49.

M. Sussman and E.G. Puckett: J. Comput. Phys., 2000, vol. 162, pp. 301–37.

J.A.S. Gonçalves, M.A.M. Costa, P.R. Henrique, and J.R. Coury: J. Hazard. Mater., 2003, vol. 99, pp. 1–3.

J.A.S. Gonçalves, M.A.M. Costa, and M.L. Aguiar: J. Hazard. Mater., 2004, vol. 116(1–2), pp. 147–57.

W. Tauber and G. Tryggvason: Comput. Fluid Dyn. J., 2000, vol. 9, p. 594.

M. Herrmann: J. Comput. Phys., 2010, vol. 229(3), pp. 745–59.

T. Ménard, S. Tanguy, and A. Berlemont: Int. J. Multiph. Flow, 2007, vol. 33(5), pp. 510–24.

G. Tomar, D. Fuster, S. Zaleski, and S. Popinet: Comput. Fluids, 2010, vol. 39(10), pp. 1864–74.

X.H. Qu, S. Revankar, X.N. Qi, and Q.J. Guo: Appl. Therm. Eng., 2021, vol. 195, p. 117160.

G. Tomar, D. Fuster, S. Zaleski, and S. Popinet: Comput. Fluids, 2010, vol. 39, pp. 1864–74.

Y. Li, Y. Huang, and K. Luo: Fuel, 2021, vol. 299, p. 120871.

I. Paden, Z. Petranović, and W. Edelbauer: Comput. Fluids, 2021, vol. 222, p. 104919.

R.S. Prakash, A. Sinha, and G. Tomar: Exp. Therm. Fluid Sci., 2018, vol. 93, pp. 45–56.

J.F. Lou, T. Hou, and J.S. Zhu: J. Comput. Mech., 2011, vol. 28(2), pp. 210–13.

V. Radhakrishna: Int. J. Multiph. Flow, 2021, vol. 138(12), p. 103591.

M. Adellberg: AIAA J., 1967, vol. 5(8), pp. 1408–15.

H.Q. Wang, C.Q. Liu, and P. He: J. Combust. Sci. Technol., 1995, vol. 03, pp. 280–85.

A. Unal: Mater. Sci. Technol., 1987, vol. 3, pp. 1029–37.

G. Chen, C. Fu, B.B. Xu, Y. Wu, F.S. Lien, and E. Yee: J. Aerosol Sci., 2022, vol. 165, p. 106035.

W. Jin, J. Xiao, H.X. Ren, C.H. Li, Q.J. Zheng, and Z.B. Tong: Powder Technol., 2022, vol. 407, p. 117622.

J. Li, C.W. Zhou, D.X. Pan, and C.S. Zhou: Comput. Math. Appl., 2019, vol. 78(4), pp. 1227–42.

R.T. He, P. Yi, T. Li, X.Y. Zhou, and Y.M. Gu: At. Sprays, 2020, vol. 30(3), pp. 189–212.

P. Yi, Y.P. Fu, and T. Li: At. Sprays, 2022, vol. 32(3), pp. 1–23.

T. Zhou and H.Z. Li: Chem. React. Eng. Technol., 1999, vol. 1, pp. 45–52.

Z. Zou, H.Z. Li, and Q.S. Zhu: Chem. React. Eng. Technol., 2014, vol. 30(1), pp. 63–70.

K.A. Estes and I. Mudawar: Int. J. Heat Mass Transf., 1995, vol. 38(16), pp. 2985–96.

Acknowledgments

This research was supported by the National Natural Science Foundation of China (51904069), the Fundamental Research Funds for the Central Universities (N2223026), and the Scientific Research Fund Project of Northeastern University at Qinhuangdao (XNY201808).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lv, C., Sun, Mh., Chen, Xx. et al. Simulation and Analysis of Atomization Performance of a Venturi Jet Pyrolysis Reactor. Metall Mater Trans B 54, 807–822 (2023). https://doi.org/10.1007/s11663-023-02727-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-023-02727-2