Abstract

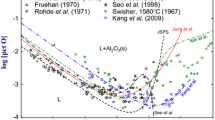

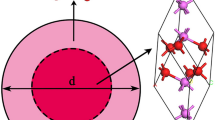

The Al-O equilibrium at high Al content during Al deoxidation process at 1873 K is reassessed in the present study due to the fact that there are still obvious discrepancies among the existing studies. The Fe-Al-O melts with varying Al content (0.01<[pct Al]<15) were equilibrated with pure solid Al2O3 at 1873 K in Al2O3 crucible under Ar (90 pct)-H2 (10 pct) mixture atmosphere, and a flux composed of CaO (30 wt pct)-Al2O3 (65 wt pct)-CaF2 (5 wt pct) was adopted to remove the inclusions to accurately measure the dissolved oxygen content in the samples. Then, based on experimental data, the interaction parameters between O and Al, as well as the equilibrium constant K, were deduced by WIPF (Wagner’s Interaction Parameter Formalism), UIP (Unified Interaction Parameter) formulism and the R–K polynomial (Redlich-Kister type polynomial), respectively. Further, the applicability concentration range of the WIPF in Fe-Al-O melts was investigated. It was found that the WIPF can be used when the concentration range of Al content is less than 9 wt pct, while the adoption of WIPF will certainly lead to a large deviation at higher Al content. Besides, when the Al content is smaller than about 2 wt pct, the WIPF can be used without considering the second-order interaction parameters between Al and O. However, the second-order interaction parameter must be introduced at a higher Al content range. Finally, the activity and activity coefficient of Al and O in Fe-Al-O melts was calculated using R–K polynomial. The results show that with the increase of Al content, the activity and activity coefficient of O decreases, while activity and activity coefficient of Al obviously increase.

Similar content being viewed by others

References

S. Kaar, K. Steineder, R. Schneider, D. Krizan, and C. Sommitsch: Scripta Mater., 2021, vol. 200, 113923.

S. Ebner, C. Suppan, A. Stark, R. Schnitzer, and C. Hofer: Mater. Design., 2019, vol. 178, p. 107862.

D. Tang and P.C. Pistorius: Metall. Mater. Trans. B, 2021, vol. 52, pp. 51–58.

M. Nabeel, M. Alba, A. Karasev, P.G. Jnsson, and N. Dogan: Metall. Mater. Trans. B, 2019, vol. 50B, pp. 1674–85.

M.K. Paek, S. Chatterjee, J.J. Pak, and I.H. Jung: Metall. Mater. Trans. B, 2016, vol. 47B, pp. 1243–62.

J.W. Cho, S. Yoo, M.S. Park, J.K. Park, and K.H. Moon: Metall. Mater. Trans. B, 2017, vol. 48B, pp. 187–96.

M.K. Paek, J.M. Jang, Y.B. Kang, et al.: Metall Mater Trans B, 2015, vol. 46B, pp. 1826–36.

R.J. Fruehan: Metall Mater Trans B, 1970, vol. 1B, pp. 3403–10.

V.E. Shevtsov: Russ. Metall., 1981, vol. 1, pp. 52–57.

H. Suito, H. Inoue, and R. Inoue: ISIJ Int., 1991, vol. 31, pp. 1381–88.

Y.J. Kang, M. Thunman, D. Sichen, T. Morohoshi, K. Mizukami, and K. Morita: ISIJ Int., 2009, vol. 49, pp. 1483–89.

L.E. Rohde, A. Choudhury, and M. Wahlster: Arch. Eisenhüttenwes., 1971, vol. 42, pp. 165–74.

J.H. Swisher: Trans. Metall. Soc. AIME, 1967, vol. 239, pp. 123–24.

H. Schenck, E. Steinmetz, and K.K. Mehta: Arch. Eisenhüttenwes., 1970, vol. 41, pp. 131–38.

D. Janke and W.A. Fischer: Arch. Eisenhüttenwes., 1976, vol. 47, pp. 195–98.

I.H. Jung, S.A. Decterov, and A.D. Pelton: Metall. Mater. Trans. B, 2004, vol. 35B, pp. 493–507.

H. Itoh, M. Hino, and S. Banya: Tetsu-to-Hagané, 1997, vol. 83, pp. 773–78.

D.C. Hilty and W. Crafts: JOM, 1950, vol. 2, pp. 414–24.

The 19th Committee in Steelmaking: Thermodynamic Data For Steelmaking, The Japan Society for Promotion of Science, Tohoku University Press, Sendai, Japan, 2010, pp. 10-13.

S. Dimitrov, A. Weyl, and D. Janke: Steel Res., 1995, vol. 66(1), pp. 3–7.

A.D. Pelton and C.W. Bale: Metall. Mater. Trans. A, 1986, vol. 17A, pp. 1211–15.

C.W. Bale and A.D. Pelton: Metall. Mater. Trans. A, 1990, vol. 21A, pp. 1997–2002.

A.D. Pelton: Metall. Mater. Trans. B, 1997, vol. 28B, pp. 869–76.

L.M. Yonemoto, T. Miki, and M. Hino: ISIJ Int, 2008, vol. 48, pp. 755–59.

T. Miki and M. Hino: ISIJ Int, 2004, vol. 44, pp. 1800–09.

T. Miki and M. Hino: ISIJ Int, 2005, vol. 45(12), pp. 1848–55.

R. Ries and K. Schwerdtfeger: Arch. Eisenhüttenwes., 1980, vol. 51, pp. 123–29.

G.K. Sigworth and J.F. Elliott: Metal. Sci., 1974, vol. 8, pp. 298–310.

N.A. Gokcen and J. Chipman: J. Met., 1953, vol. 197, pp. 173–78.

A. McLean and H.B. Bell: J. Iron Steel Inst., 1965, vol. 203, pp. 123–30.

C.H.P. Lupis and J.F. Elliott: Acta Mater., 1966, vol. 14(9), pp. 1019–32.

H. Fukaya, K. Kajikawa, A. Malfliet, et al.: Metall Mater Trans B, 2018, vol. 49B, pp. 2389–99.

A. Hayashi, T. Uenishi, H. Kandori, et al.: ISIJ Int., 2008, vol. 48(11), pp. 1533–41.

Acknowledgments

The authors gratefully acknowledge the financial support of this research by the National Natural Science Foundation of China (Grant Nos. 52104293 and 51774025), the China Postdoctoral Science Foundation (Grant No 2021M690367), and Fundamental Research Funds for the Central Universities (Grant No FRF-IDRY-20-002).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, J., Han, L. & Yan, B. Reassessment of Aluminium-Oxygen Equilibrium in High Al Molten Steel During Aluminium Deoxidation Process at 1873 K. Metall Mater Trans B 53, 2512–2522 (2022). https://doi.org/10.1007/s11663-022-02546-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-022-02546-x