Abstract

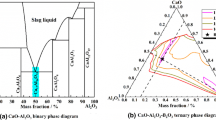

To explore the relationship between typical components, structure, and properties, and provide theoretical guidance for non-reactive aluminate slag, the effects of BaO content and CaO/Al2O3 (C/A) ratio on microstructure and properties of aluminate slag were investigated with Fourier-transform infrared and Raman spectroscopies, hemisphere melting temperature apparatus, rotating viscometer, and four-electrode conductivity tester in this study. The results showed that, when the BaO contents changed from 2 to 10 wt pct and C/A ratio changed from 1.2 to 1.4, the more complex Al–O network were transformed into simpler structure. Meanwhile, combing the slag melting temperature changed minimally, indicating the degree of superheat slightly influenced the slag viscosity, the slag viscosity was mainly influenced by polymerization degree. Owing to the increased Ba2+ and Ca2+ concentration and the decreased polymerization degree of the slag network structure, the conductivity of the slag increased. Furthermore, on increasing BaO content and decreasing C/A ratio, the break temperature on the viscosity–temperature curve decreased. This trend was related to the precipitation of the mineral phases Ca12Al14O33, CaF2, and BaAl2O4. It was also shown that a high BaO content and low C/A ratio help improve the lubricating properties of aluminate slag.

Similar content being viewed by others

References

W.L. Wang, K. Blazek, and A. Cramb: Metall. Mater. Trans. B., 2008, vol. 39B, pp. 66–74.

J.R. Allwardt: Am. Mineral., 2005, vol. 90, pp. 1218–22.

G.H. Zhang and K.C. Chou: Metall. Mater. Trans. B., 2012, vol. 43B, pp. 849–55.

G.H. Zhang, W.W. Zheng, S. Jiao, and K.C. Cho: ISIJ. Int., 2017, vol. 57, pp. 2091–96.

C.B. Shi, M.D. Seo, J.W. Cho, and S.H. Kim: Metall. Mater. Trans. B., 2014, vol. 45B, pp. 1081–97.

B. Lu, K. Chen, W. Wang, and B. Jiang: Metall. Mater. Trans. B., 2014, vol. 45B, pp. 1496–509.

Z.L. Piao, L.G. Zhu, S. Qu, K. Liu, X.J. Wang, P.C. Xiao, J.Y. Zhou, and B. Wang: J. Non. Cryst. Solids., 2020, vol. 542, p. 120111.

B. Lu and W. Wang: Metall. Mater. Trans. B., 2015, vol. 46B, pp. 852–62.

Z.J. Wang and I. Sohn: J. Am. Ceram. Soc., 2018, vol. 101, pp. 4285–96.

L.J. Zhou, H. Luo, W.L. Wang, H.F. Wu, E.Z. Gao, Y. Zhou, and D.Y. Huang: Int. J. Miner. Metall. Mater., 2021, vol. 53, pp. 1–7.

H. Singh, Q.F. Shu, G. King, Z.Q. Liang, Z.F. Wang, W. Cao, M. Huttula, and T. Fabritius: J. Am. Ceram. Soc., 2021, vol. 104, pp. 4505–17.

X.B. Yan, W.J. Pan, X.S. Wang, X.B. Zhang, S.P. He, and Q. Wang: Metall. Mater. Trans. B., 2021, vol. 52B, pp. 2526–35.

Z. Li, X.C. You, M. Li, Q. Wang, S.P. He, and Q.Q. Wang: Metals., 2019, vol. 9, p. 142.

R.Z. Xu, J.L. Zhang, W.X. Han, Z.Y. Chang, and K.X. Jiao: Ironmak. Steelmak., 2020, vol. 47, pp. 168–72.

S. Sukenaga, N. Saito, K. Kawakami, and K. Nakashima: ISIJ Int., 2006, vol. 46, pp. 352–58.

T. Wu, W. Yang, C. Zhang, H.C. Wang, and J. Lei: J. Non. Cryst. Solids., 2021, vol. 570, p. 121044.

E. Gao, W. Wang, and L. Zhang: J. Non. Cryst. Solids., 2017, vol. 473, pp. 79–86.

X.H. Huang, J.L. Liao, K. Zheng, H.H. Hu, F.M. Wang, and Z.T. Zhang: Ironmak. Steelmak., 2014, vol. 41, pp. 67–74.

H. Kim, W.H. Kim, J.H. Park, and D.J. Min: Steel Res. Int., 2010, vol. 81, pp. 17–24.

J.H. Park, D.J. Min, and H.S. Song: Metall. Mater. Trans. B., 2004, vol. 35B, pp. 269–75.

Y. Liu, X. Lv, B. Li, and C. Bai: Ironmak. Steelmak., 2017, vol. 45, pp. 492–501.

L. Zhang, W. Wang, S. Xie, K. Zhang, and I. Sohn: J. Non Cryst. Solids., 2017, vol. 460, pp. 113–8.

L. Zhou, W. Wang, B. Lu, and G. Wen: Metal Mater. Int., 2015, vol. 21, pp. 126–33.

T.S. Kim and J.H. Par: ISIJ Int., 2014, vol. 54, pp. 2031–38.

H. Shao, E. Gao, W. Wang, and L. Zhang: J. Am Ceram. Soc., 2019, vol. 102, pp. 4440–49.

J.X. Gao, G.H. Wen, T. Huang, B.W. Bai, P. Tang, and Q. Liu: J. Am. Ceram. Soc., 2016, vol. 99, pp. 3941–47.

G.H. Zhang, W.W. Zheng, and K.C. Chou: Metall. Mater. Trans. B., 2017, vol. 48B, pp. 1134–38.

G.H. Zhang, B.J. Yan, K.C. Chou, and F.S. Li: Metall. Mater. Trans. B., 2011, vol. 42, pp. 261–64.

X. Feng, W. Yao, and J.L. Li: Continuous Casting., 2021, vol. 46, pp. 38–42.

Acknowledgments

The authors would like to deeply appreciate the fund support from the National Natural Science Foundation of China (Grant No. 51804004) and the Key projects of National Natural Science Foundation of China (Grant No. U1760202).

Conflict of interest

We declare that there are no known conflicts of interest associated with this publication and there has been no significant financial support for this work that could have influenced its outcome.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lei, J., Yang, W., Sheng, Gy. et al. Effects of BaO Content and CaO/Al2O3 Ratio on the Properties and Structure of Aluminate Slag. Metall Mater Trans B 53, 2239–2247 (2022). https://doi.org/10.1007/s11663-022-02523-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-022-02523-4