Abstract

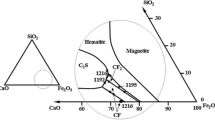

SiO2 plays an important role in the formation of calcium ferrite as a main binding phase in iron ore sinter. But the mechanism of SiO2 influence on the crystallization of calcium ferrite has been still unclear. The crystallization behavior of Fe2O3–CaO–SiO2–Al2O3 melt in a non-equilibrium state was investigated using X-ray diffraction, optical microscopy, scanning electron microscopy, and energy-dispersive spectroscopy. The results show that SiO2 was an essential impact on the amount formation and morphology of calcium ferrite crystallization during the sintering process. With the increase of SiO2 content, the crystal morphology changed in the order of blocky, columnar, acicular to grains. The crystallization size increased first and then decreased. The crystallization sequence of samples with 4.0 mass pct SiO2 was observed as (Fe2O3, C4F14, SFCA-I) → CF→ SFCA → β-C2S. Increase of the cooling rate promoted the formation of Fe2O3, C4F14, and glass phase and the transformation of SFCA-I to SFCA. However, it also inhibited the crystallization of CF and SFCA, simultaneously the transformation of β-C2S to γ-C2S. The thermodynamic calculation shows that the crystallization temperatures and the primary crystal phase varied with the increase of SiO2 content, which agreed with the experimental results. In addition, the increase of SiO2 significantly reduced the liquid phase amount, simultaneously increased its viscosity at high-temperature range, which was contributing to decrease of the crystallization size.

Similar content being viewed by others

References

C.E. Loo and W. Leung: ISIJ Int., 2003, vol. 43(9), pp. 1393–1402.

L.X. Yang and C.E. Loo: ISIJ Int., 1997, vol. 37(5), pp. 449–57.

S.L. Wu, J. Zhu, J.X. Fan, G.L. Zhang, and S.G. Chen: ISIJ Int., 2013, vol. 53(9), pp. 1561–70.

B.G. Ellis, C.E. Loo, and D. Witchard: Ironmak. Steelmak., 2007, vol. 34(2), pp. 99–108.

H. Guo and X.M. Guo: Metall. Mater. Trans. B., 2018, vol. 49B(4), pp. 1974–84.

Y.L. Liu, J.S. Wang, H.J. Zhang, J.Z. Liu, X.F. She, and Q.G. Xue: Ironmak. Steelmak., 2015, vol. 42(5), pp. 358–65.

S.L. Wu, G.L. Zhang, S.G. Chen, and B. Su: ISIJ Int., 2014, vol. 54(3), pp. 582–88.

A. Cores, A. Babich, M. Muñiz, S. Ferreira, and J. Mochon: ISIJ Int., 2010, vol. 50(8), pp. 1089–98.

L.H. Hsieh and J.A. Whiteman: ISIJ Int., 1989, vol. 29(8), pp. 625–34.

T.J. Park, J.S. Choi, and D.J. Min: Met. Mater. Int., 2020, vol. 26, pp. 532–40.

N.A.S. Webster, D.P. O’Dea, B.G. Ellis, and M.I. Pownceby: ISIJ Int., 2017, vol. 57(1), pp. 41–47.

A.M. Nyembwe and A.M. Garbers-Craig: Ironmak. Steelmak., 2014, vol. 41(3), pp. 173–81.

Z. Wang, D. Pinson, S. Chew, B.J. Monaghan, H. Rogers, and G.Q. Zhang: ISIJ Int., 2016, vol. 56(4), pp. 505–12.

L. Lu, R.J. Holmes, and J.R. Manuel: ISIJ Int., 2007, vol. 47(3), pp. 349–58.

S.Y. Cheng, M. Shevchenko, P.C. Hayes, and E. Jak: Metall. Master. Trans. B., 2021, vol. 52B, pp. 1891–1914.

N.A.S. Webster, M.I. Powceby, and I.C. Madsen: ISIJ Int., 2013, vol. 53(8), pp. 1334–40.

N.A.S. Webster, M.I. Powceby, I.C. Madsen, A.J. Studer, J.R. Manuel, and J.A. Kimpton: Metall. Mater. Trans. B., 2014, vol. 45B(6), pp. 2097–2105.

J.D.G. Hamilton, B.F. Hoskins, W.G. Mumme, W.E. Borbidge, and M.A. Montague: Neues Jahrb Min. Abh., 1989, vol. 161(1), pp. 1–26.

M.I. Pownceby, J.M.F. Clout, and M.J. Fisher-White: Trans. Inst. Min. Metall., 1998, vol. 107, pp. C1-10.

M.I. Pownceby and J.M.F. Clout: Trans Inst. Min. Metall., 2003, vol. 112, pp. 44–51.

M.I. Pownceby and T.R.C. Patrick: Eur. J. Mineral., 2000, vol. 12, pp. 455–68.

M.I. Pownceby and T.R.C. Patrick: Metall Mater. Trans. B., 2002, vol. 33B(1), pp. 79–89.

X. Ding and X.M. Guo: Metall. Mater. Trans. B., 2014, vol. 45B, pp. 1221–31.

N.A.S. Webster, M.I. Pownceby, I.C. Madsen, and J.A. Kimpton: Metall Mater. Trans. B., 2012, vol. 43B(6), pp. 1344–57.

K.H. Yajima and S.M. Jung: ISIJ Int., 2012, vol. 52(3), pp. 535–37.

L.H. Hsieh and J.A. Whiteman: ISIJ Int., 1993, vol. 33(4), pp. 462–73.

B. Cai, T. Watanabe, C. Kamijo, and M. Susa: ISIJ Int., 2018, vol. 58(4), pp. 642–51.

C.Y. Ding, X.W. Lv, S.W. Xue, J. Qiu, Y. Chen, and C.G. Gang: ISIJ Int., 2017, vol. 57(4), pp. 634–42.

T.J. Park, J.S. Choi, and D.J. Min: Metall Mater. Trans. B., 2019, vol. 50B(2), pp. 790–98.

W. Wang, D.W. Yang, Z.L. Ou-Yang, R.S. Xu, and M.M. Song: Metall Mater. Trans. B., 2019, vol. 50B(2), pp. 678–87.

X.H. Fan: Principle and Technology of Optimum Blending of Iron Ore Sintering, Metallurgical Industry Press, Beijing, 2013, pp. 62–65.

Z.J. Wang, Y. Sun, S. Sridhar, M. Zhang, and Z. Zhang: Metall Mater. Trans. B., 2015, vol. 46B(5), pp. 2246–54.

Z.J. Wang, Y. Sun, S. Sridrar, Z. Mei, and Z. Zhang: Metall Mater. Trans. B., 2017, vol. 48B(1), pp. 527–37.

R.T.D. Cruz and S.R. Bragança: Ceramic. Int., 2015, vol. 41, pp. 4775–81.

I. Nettleship, K.G. Slavick, Y.J. Kim, and W.M. Kriven: J. Am. Ceramic. Soc., 1992, vol. 75(9), pp. 2400–06.

R.G. Chang, Y.T. Yan, J.Y. Zhang, Z.L. Zhu, and J.H. Gu: Thin Solid Films., 2020, vol. 712, p. 138279.

C.W. Bale, P. Chartrand, S.A. Degterov, G. Eriksson, K. Hack, R. Ben Mahfoud, J. Melancon, A.D. Pelton, and S. Petersen: Calphad., 2002, vol. 26(2), pp. 189–228.

R. Roscoe: Br. J. Appl. Phys., 1952, vol. 3, pp. 267–69.

Acknowledgments

The authors are grateful to the National Natural Science Foundation of China (Nos. 51774029 and U1460201) for financial support of this research. On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted December 14, 2021; accepted March 14, 2022.

Rights and permissions

About this article

Cite this article

Xin, RF., Guo, XM. Effect of SiO2 on Crystallization of Calcium Ferrites in Fe2O3–CaO–SiO2–Al2O3 System in Cooling Process. Metall Mater Trans B 53, 1904–1919 (2022). https://doi.org/10.1007/s11663-022-02501-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-022-02501-w