Abstract

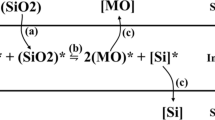

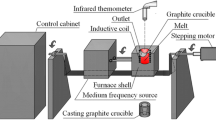

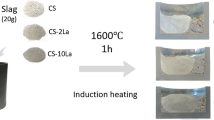

Kinetic research on impurity removal from metallurgical-grade silicon is an important theoretical basis for silicon product upgrading and optimization. In this paper, the oxidation mechanism of boron removal from metallurgical-grade silicon by CaO-SiO2 slag at 1823 K was investigated by experimental measurements and ab initio molecular dynamics simulation calculation. By fitting the relationship between refining time and boron concentration in refined silicon, the apparent rate constant and the mass transfer coefficient of boron were obtained. The experimental results showed that there was no significant change in silicon loss rate with increasing refining time. Ab initio molecular dynamics simulation shows that there was an interaction between boron atom and three O atoms in the silicon melt, which results in the oxidation of boron in silicon to borate \(\text{(}{\text{BO}}_{3}^{3-}\text{)}\). The particle trajectories in CaO-SiO2 molten slag were statistically analyzed by Materials Studio software, and it is calculated that the diffusion coefficient \({D}_{\text{B}}\) of boron in CaO-SiO2 slag at 1823 K was found to be 1.29 × 10−8 m2·s−1.

Similar content being viewed by others

References

M. Fang, C.H. Lu, L.Q. Huang, H.X. Lai, J. Chen, J.T. Li, W.H. Ma, P.F. Xing, and X.T. Luo: Sep. Sci. Technol., 2014, vol. 49, pp. 2261–70. https://doi.org/10.1080/01496395.2014.919323.

J.J. Wu, W.H. Ma, Y.L. Li, B. Yang, D.C. Liu, and Y.N. Dai: Trans. Nonferrous Met. Soc. China., 2013, vol. 23, pp. 260–65. https://doi.org/10.1016/s1003-6326(13)62454-1.

M. Fang, C.H. Lu, L.Q. Huang, H.X. Lai, J. Chen, J.T. Li, W.H. Ma, P.F. Xing, and X.T. Luo: Ind. Eng. Chem. Res., 2014, vol. 53, pp. 972–79. https://doi.org/10.1021/ie403047m.

L.Q. Huang, J. Chen, M. Fang, S. Thomas, A. Danaei, X.T. Luo, and M. Barati: J. Clean. Prod., 2018, vol. 186, pp. 718–25. https://doi.org/10.1016/j.jclepro.2018.03.152.

Y. Tan, X.L. Guo, S. Shi, W. Dong, and D.C. Jiang: Vacuum., 2013, vol. 93, pp. 65–70. https://doi.org/10.1016/j.vacuum.2012.12.010.

S.D. Hu, Y.C. Dai, A. Gagnoud, Y. Fautrelle, R. Moreau, Z.M. Ren, K. Deng, C.J. Li, and X. Li: J. Alloy. Compd., 2017, vol. 722, pp. 108–15. https://doi.org/10.1016/j.jallcom.2017.06.084.

J. Dietl: Solar Cells., 1983, vol. 10, pp. 145–54. https://doi.org/10.1016/0379-6787(83)90015-7.

Q. Wang, W. Dong, Y. Tan, D.C. Jiang, C. Zhang, and X. Peng: Rare Met., 2011, vol. 30, pp. 274–77. https://doi.org/10.1007/s12598-011-0382-6.

K.X. Wei, D.M. Zheng, W.H. Ma, B. Yang, and Y.N. Dai: SILICON., 2015, vol. 7, pp. 269–74. https://doi.org/10.1007/s12633-014-9228-9.

Z.F. Xia, J.J. Wu, W.H. Ma, Y. Lei, K.X. Wei, and Y.N. Dai: Sep. Purif. Technol., 2017, vol. 187, pp. 25–33. https://doi.org/10.1016/j.seppur.2017.06.037.

Y.V. Meteleva-Fischer, Y. Yang, R. Boom, B. Kraaijveld, and H. Kuntzel: JOM., 2012, vol. 64, pp. 957–67. https://doi.org/10.1007/s11837-012-0383-4.

J.J. Wu, D. Yang, M. Xu, W.H. Ma, Q. Zhou, Z.F. Xia, Y. Lei, K.X. Wei, S.Y. Li, Z.J. Chen, and K.Q. Xie: Sep. Purif. Rev., 2020, vol. 49, pp. 68–88. https://doi.org/10.1080/15422119.2018.1523191.

S. Shi, Y. Tan, D.C. Jiang, S.Q. Qin, X.L. Guo, and H.K. Asghar: Sep. Purif. Technol., 2015, vol. 152, pp. 32–36. https://doi.org/10.1016/j.seppur.2015.08.002.

Y.Q. Li and L.F. Zhang: Sep. Purif. Rev., 2021, vol. 50, pp. 115–38. https://doi.org/10.1080/15422119.2019.1623253.

Y. Delannoy, C. Alemany, K.I. Li, P. Proulx, and C. Trassy: Sol. Energy Mater. Sol. Cells., 2002, vol. 72, pp. 69–75. https://doi.org/10.1016/s0927-0248(01)00151-9.

B.P. Lee, H.M. Lee, D.H. Park, J.S. Shin, T.U. Yu, and B.M. Moon: Sol. Energy Mater. Sol. Cells., 2011, vol. 95, pp. 56–58. https://doi.org/10.1016/j.solmat.2010.02.011.

J.J. Wu, Y.L. Li, W.H. Ma, K.X. Wei, B. Yang, and Y.N. Dai: Trans. Nonferrous Met. Soc. China., 2014, vol. 24, pp. 1231–36. https://doi.org/10.1016/s1003-6326(14)63183-6.

Y.Q. Li, W. Chen, J. Lu, X.H. Lei, and L.F. Zhang: J. Electron. Mater., 2021, vol. 50, pp. 1386–96. https://doi.org/10.1007/s11664-020-08651-4.

Q. He, J.J. Wu, F. Yang, Y.Q. Zhou, K. Liu, and W.H. Ma: Sep. Purif. Rev., 2021, https://doi.org/10.1080/15422119.2021.1986409.

L.A.V. Teixeira and K. Morita: ISIJ Int., 2009, vol. 49, pp. 783–87. https://doi.org/10.2355/isijinternational.49.783.

J. Cai, J.T. Li, W.H. Chen, C. Chen, and X.T. Luo: Trans. Nonferrous Met. Soc. China., 2011, vol. 21, pp. 1402–06. https://doi.org/10.1016/s1003-6326(11)60873-x.

J.J. Wu, K. Liu, M. Xu, W.H. Ma, B. Yang, and Y.N. Dai: J. Min. Metall. B., 2014, vol. 50B, pp. 83–86. https://doi.org/10.2298/jmmb140202005w.

Q. Zhou, J.J. Wu, W.H. Ma, Z.J. Chen, Y. Lei, and K.X. Wei: JOM., 2020, vol. 72, pp. 2670–75. https://doi.org/10.1007/s11837-019-03847-4.

E. Krystad, K. Tang, and G. Tranell: JOM., 2012, vol. 64, pp. 968–72. https://doi.org/10.1007/s11837-012-0382-5.

H.X. Lai, L.Q. Huang, C.H. Lu, M. Fang, W.H. Ma, P.F. Xing, J.T. Li, and X.T. Luo: JOM., 2016, vol. 68, pp. 2371–80. https://doi.org/10.1007/s11837-015-1656-5.

Ø.S. Sortland and M. Tangstad: Metall. Mater. Trans. E., 2014, vol. 1E, pp. 211–25. https://doi.org/10.1007/s40553-014-0021-x.

L.A.V. Teixeira, Y. Tokuda, T. Yoko, and K. Morita: ISIJ Int., 2009, vol. 49, pp. 777–82. https://doi.org/10.2355/isijinternational.49.777.

N.Y. He, D. Yang, M. Xu, J.J. Wu, K.X. Wei, and W.H. Ma: Metall. Mater. Trans. B., 2021, vol. 52B, pp. 1830–38. https://doi.org/10.1007/s11663-021-02149-y.

K. Suzuki, T. Kumagai, and N. Sano: ISIJ Int., 1992, vol. 32, pp. 630–34. https://doi.org/10.2355/isijinternational.32.630.

H. Nishimoto, Y. Kang, T. Yoshikawa, and K. Morita: High. Temp. Mater. Process., 2012, vol. 31, pp. 471–77. https://doi.org/10.1515/htmp-2012-0083.

M.S. Islam and M.A. Rhamdhani: Metall. Mater. Trans. B., 2018, vol. 49B, pp. 3171–85. https://doi.org/10.1007/s11663-018-1424-3.

G.A. Heiser, R.C. Shukla, and E.R. Cowley: Phys. Rev. B., 1986, vol. 33, pp. 2158–62. https://doi.org/10.1103/PhysRevB.33.2158.

F.M. Wang, J.J. Wu, W.H. Ma, Y. Lei, K.X. Wei, and B. Yang: J. Chem. Thermodyn., 2018, vol. 118, pp. 215–24. https://doi.org/10.1016/j.jct.2017.11.018.

Acknowledgments

The authors wish to acknowledge the financial support on this research from the National Natural Science Foundation of China (22078140), the Talent Training Program of Yunnan of China (202005AC160041), and the major R&D project of Yunnan of China (202002AB0800020102).

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

He, Q., He, N., Yang, D. et al. Oxidation Kinetics and Mechanism of Boron in Metallurgical-Grade Silicon Melt by CaO-SiO2 Slag Refining. Metall Mater Trans B 53, 1841–1850 (2022). https://doi.org/10.1007/s11663-022-02493-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-022-02493-7