Abstract

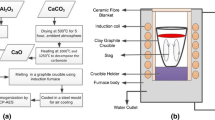

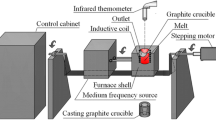

To enhance the removal of B from metallurgical-grade Si (MG-Si) by the CaO-SiO2-CaCl2 slag refining technique, Ar gas was injected during the refining process. The effects of the refining time, Ar gas flow rate, and the blowing-pipe immersion depth on the removal of B from MG-Si were studied. The results show that the injection of Ar gas can effectively stir and then mix the Si and slag phases, resulting in an increase in the Si/slag contact area and in an acceleration of the mass transfer rate of B. With the combined slag-refining and Ar gas-blowing approach, the reaction time for the removal of B was reduced to 5 min from 75 min required with the slag-refining approach. Correspondingly, the content of B was reduced from 23.91 to 10.42 ppmw, with a removal efficiency of 56.42%. The results were confirmed by the coupled large-eddy simulation model and the volume of fluid multiphase flow model.

Similar content being viewed by others

References

J.R. Davis Jr, A. Rohatgi, R. Hopkins, P. Blais, P. Rai-Choudhury, J. McCormick, and H. Mollenkopf, IEEE Trans. Electron Devices 27, 677–687 (1980).

S. Shi, X. Guo, G. An, D. Jiang, S. Qin, J. Meng, P. Li, Y. Tan, H.M. Noorul, and Huda Khan Asghar, Separat. Purification Technol. 215, 242–248 (2019).

M. Fang, C.H. Lu, L.Q. Huang, H.X. Lai, J. Chen, J.T. Li, W.H. Ma, P.F. Xing, and X.T. Luo, Separ. Sci. Technol. 49, 2261–2270 (2014).

E.J. Jung, B.M. Moon, S.H. Seok, and D.J. Min, Energy 66, 35–40 (2014).

A. Hosseinpour and L.T. Khajavi, Metall. Mater. Trans. B 50, 1773–1781 (2019).

Q. Zhou, J.J. Wu, W.H. Ma, Z.J. Chen, Y. Lei, and K.X. Wei, JOM 72, 2670–2675 (2020).

A.-K. Rowaid, Y. Li, and L. Zhang, Int. J. Miner. Metall. Mater. 25, 1439–1446 (2018).

A.-K. Rowaid, Y. Li, and L. Zhang, Metall. Res. Technol. 115, 312 (2018).

L.K. Jakobsson and M. Tangstad, Metall. Mater. Trans. B 45, 1644–1655 (2014).

L. Zhang, Y. Tan, F.M. Xu, J. Li, H. Wang, and Z. Gu, Separt. Sci. Technol. 48, 1140–1144 (2013).

M. Fang, C. Lu, L. Huang, H. Lai, J. Chen, X. Yang, J. Li, W. Ma, P. Xing, and X. Luo, Ind. Eng. Chem. Res. 53, 12054–12062 (2014).

J. Wu, W. Ma, B. Jia, B. Yang, D. Liu, and Y. Dai, J. Non. Cryst. Solids 358, 3079–3083 (2012).

Q. Zhou, J. Wen, J. Wu, W. Ma, M. Xu, K. Wei, Z. Zhang, L. Zhang, and J. Xu, J. Clean. Prod. 229, 1335–1341 (2019).

D.W. Luo, N. Liu, Y.P. Lu, G.L. Zhang, and T.J. Li, Trans. Nonferrous Met. Soc. China 21, 1178–1184 (2011).

J.F. White and S. Du, Metall. Mater. Trans. B 45, 96–105 (2014).

J. Safarian, K. Tang, J.E. Olsen, S. Andersson, G. Tranell, and K. Hildal, Metall. Mater. Trans. B 47, 1063–1079 (2016).

Ø.S. Sortland and M. Tangstad, Metall. Mater. Trans. E 1, 211–225 (2014).

J. Wu, Y. Zhou, W. Ma, M. Xu, and B. Yang, Metall. Mater. Trans. B 48, 22–26 (2017).

J. Smagorinsky, Mon. Weather Rev. 91, 99–164 (1963).

Q.G. BoQu, Q. Li, J. Lian, and B. Yin, J. Chang’an Univ. 33, 32–36 (2013).

Y. Wang, X.D. Ma, and K. Morita, Metall. Mater. Trans. B 45, 334–337 (2014).

H. Chen, X. Yuan, K. Morita, Y. Zhong, X. Ma, Z. Chen, and Y. Wang, Metall. Mater. Trans. B 50, 2088–2094 (2019).

Acknowledgments

The authors are grateful for support from the National Natural Science Foundation of China (No. 51604023), the Fundamental Research Funds for the Central Universities (No. FRF-TP-18-029A1), the USTB-NTUT Joint Research Program, the High Steel Center (HSC) at Yanshan University, the Beijing International Center of Advanced and Intelligent Manufacturing of High Quality Steel Materials (ICSM), the Beijing Key Laboratory of Green Recycling and Extraction of Metals (GREM), and the High Quality Steel Consortium (HQSC) at the University of Science and Technology Beijing (USTB), China.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, Y., Chen, W., Lu, J. et al. Boron Removal from Metallurgical-Grade Silicon by Slag Refining and Gas Blowing Techniques: Experiments and Simulations. J. Electron. Mater. 50, 1386–1396 (2021). https://doi.org/10.1007/s11664-020-08651-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-020-08651-4