Abstract

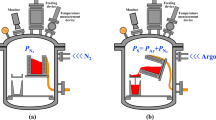

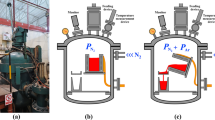

In this paper, the influence mechanism of pressure on nitrogen bubble formation during solidification process in 30Cr15Mo1N ingot was investigated by experimental and calculation methods. The effects of pressure on the critical nucleation radius and the growth rate of nitrogen bubbles were investigated. The growth of nitrogen bubbles was closely associated with the direction of solidification. In addition, nitrogen bubbles were generally egg-shaped and spherical in the columnar and equiaxed regions, respectively. With increasing pressure from 0.3 to 0.5 MPa, an increment existed in the critical nucleation radius and a decrement in the growth rate of nitrogen bubbles, mainly caused by the increment of the Gibbs free energy change of the system for nucleation and the internal pressure in the nitrogen bubbles, respectively. It led to decrements in number and mean area of nitrogen bubbles in 30Cr15Mo1N ingots with increasing pressure from 0.3 to 0.5 MPa. Based on the effect of pressure on formation of nitrogen bubbles, a special fitting formula was proposed to obtain the critical pressure for the 30Cr15Mo1N cylindrical ingot without nitrogen bubbles: \(P_{{\text{c}}} = {\text{max}}\left\{ {0.8867[{\text{pct\;N}}]_{0} + 0.098,0.053e^{{[{\text{pct\; N}}]_{0} /0.212}} + 0.0415} \right\},\) which is applicable under low pressure (≤ 2 MPa).

Similar content being viewed by others

References

Z.Y. He, H.B. Li, Z.W. Ni, H.C. Zhu, Z.H. Jiang, H. Feng, and D.S. Mao: Steel Res. Int., 2021, vol. 92, p. 2100197.

W. Trojahn, E. Streit, H.A. Chin, and D. Ehlert: Materialwiss. Werkstofftech., 1999, vol. 30, pp. 605–11.

M.B. Horovitz, F.B. Neto, A. Garbogini, and A.P. Tcshiptschin: ISIJ Int., 1996, vol. 36, pp. 840–45.

H. Feng, Z.H. Jiang, H.B. Li, P.C. Lu, S.C. Zhang, H.C. Zhu, B.B. Zhang, T. Zhang, D.K. Xu, and Z.G. Chen: Corros Sci., 2018, vol. 144, pp. 288–300.

P.C. Lu, H.B. Li, H. Feng, Z.H. Jiang, H.C. Zhu, Z.Z. Liu, and T. He: Metall. Mater. Trans. B., 2021, vol. 52B, pp. 2210–23.

H.C. Zhu, Z.H. Jiang, H.B. Li, H. Feng, S.C. Zhang, G.H. Liu, J.H. Zhu, P.B. Wang, B.B. Zhang, and G.W. Fan: Metall. Mater. Trans. B., 2017, vol. 48B, pp. 2493–2503.

Y.H. Park, J.W. Kim, S.K. Kim, Y.D. Lee, and Z.H. Lee: Metall. Mater. Trans. B., 2003, vol. 34B, pp. 313–20.

Y. Han, H.B. Li, H. Feng, K.M. Li, Y.Z. Tian, and Z.H. Jiang: J. Mater. Sci. Technol. (Shenyang, China)., 2021, vol. 65, pp. 210–15.

Y. Han, H.B. Li, H. Feng, Y.Z. Tian, Z.H. Jiang, and T. He: Mater. Sci. Eng. A., 2021, vol. 814, p. 141235.

A. Mitchell and H. Frederiksson: J. Mater. Sci., 2004, vol. 39, pp. 7275–83.

Y.H. Park and Z.H. Lee: Mater. Sci. Eng. A., 2001, vol. 297, pp. 78–84.

M.B. Cortie and J.H. Potgieter: Metall. Trans. A., 1991, vol. 22, pp. 2173–79.

K.J. Dai, B. Wang, F. Xue, S.S. Liu, J.K. Huang, and J.Y. Zhang: Metall. Mater. Trans. B., 2018, vol. 49B, pp. 2011–21.

K.W. Li, J.H. Liu, J. Zhang, and S.B. Shen: Metall. Mater. Trans. B., 2017, vol. 48B, pp. 2136–46.

Z. Yu, O. Hemminger, and L.S. Fan: Chem. Eng. Sci., 2007, vol. 62, pp. 7172–83.

R.C. Atwood and P.D. Lee: Acta Mater., 2003, vol. 51, pp. 5447–66.

A.V. Catalina, S. Sen, D.M. Stefanescu, and W.F. Kaukler: Metall. Mater. Trans. A., 2004, vol. 35A, pp. 1525–38.

Z.H. Jiang, H.B. Li, Z.P. Chen, Z.Z. Huang, D.L. Zou, and L.K. Liang: Steel Res. Int., 2005, vol. 76, pp. 740–45.

Y. Kobayashi, H. Todoroki, N. Shiga, and T. Ishii: ISIJ. Int., 2012, vol. 9, pp. 1601–06.

K.F. Kelton and A.L. Greer: Nucleation in Condensed Matter: Applications in Materials And Biology, Elsevier, Oxford, 2010.

R.P. Sear: J. Phys. Condens. Matter., 2007, vol. 19, p. 033101.

R.P. Sear: CrystEngComm., 2014, vol. 16, pp. 6506–22.

H.R. Pruppacher and J.D. Klett: Microphysics of Clouds and Precipitation: Reprinted 1980, Springer, New York, 2012.

H. Shim, Y. Jeon, J. Yeo, and G. Lee: New J. Phys., 2015, vol. 17, p. 063026.

X.Y. Liu: J. Chem. Phys., 2000, vol. 112, pp. 9949–55.

D.W. Oxtoby: J. Phys.: Condens. Matter., 1992, vol. 4, pp. 7627–50.

P.G. Debenedetti: Metastable Liquids, Princeton University Press, Princeton, 2021.

P. Wei and S.Y. Hsiao: Int. J. Heat Mass Transf., 2012, vol. 55, pp. 8129–38.

P. Kapranos, C. Carney, A. Pola, and M. Jolly: Casting, Semi-solid Forming and Hot Metal Forming, Comprehensive Materials Processing, Elsevier, Amsterdam, 2014, pp. 39–67.

H.C. Zhu, H.B. Li, Z.Y. He, H. Feng, Z.H. Jiang, and T. He: ISIJ Int., 2021, vol. 61(6), p. 1889. https://doi.org/10.2355/isijinternational.ISIJINT-2021-010.

A.P. Mouritz: Introduction to Aerospace Materials, Elsevier, Oxford, 2012.

S. Louhenkilpi: Continuous Casting of Steel, Treatise on Process Metallurgy, Elsevier, Oxford, 2014.

E.J. Pickering: ISIJ Int., 2013, vol. 53, pp. 935–49.

H.C. Zhu, Z.H. Jiang, H.B. Li, J.H. Zhu, H. Feng, S.C. Zhang, B.B. Zhang, P.B. Wang, and G.H. Liu: Steel Res. Int., 2017, vol. 88, p. 1600509.

Z.H. Jiang, H.C. Zhu, H.B. Li, G.H. Liu, P.B. Wang, J.H. Zhu, S.C. Zhang, and H. Feng: ISIJ Int., 2018, vol. 58, pp. 107–13.

Z.X. Cui and B.X. Liu: Metallurgy and Heat Treatment Theory, Harbin Institute of Technology Press, Harbin, 1998.

H.C. Zhu, H.B. Li, Z.Y. He, H. Feng, and Z.H. Jiang: Metall. Mater. Trans. B., 2020, vol. 51B, pp. 1–17.

J.A. Sekhar, G.J. Abbaschian, and R. Mehrabian: Mater. Sci. Eng., 1979, vol. 40, pp. 105–10.

A.F. Ilkhchy, M. Jabbari, and P. Davami: Int. Commun. Heat Mass Transf., 2012, vol. 39, pp. 705–12.

H.C. Zhu, H.B. Li, Z.Y. He, H. Feng, and Z.H. Jiang: Metall. Mater. Trans. B., 2021, vol. 52B, pp. 3235–45.

Acknowledgments

The present research was financially supported by National Natural Science Foundation of China (nos. U1960203, 51904065 and 51774074), Talent Project of Revitalizing Liaoning (XLYC1902046), China National Postdoctoral Program for Innovative Talents (grant no. BX20200076) and Elite Program of Southern Taihu Lake. Conflict of interest On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, HB., He, ZY., Zhu, HC. et al. Influence Mechanism of Pressure on Nitrogen Bubble Formation During Solidification Process in 30Cr15Mo1N Ingot. Metall Mater Trans B 53, 1721–1732 (2022). https://doi.org/10.1007/s11663-022-02482-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-022-02482-w