Abstract

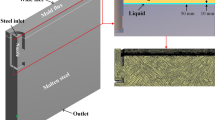

The interfacial reaction between molten steel and mold flux causes MnO accumulation and SiO2 reduction in the mold flux during the continuous casting of medium Mn steel. A three-dimensional reaction model in the mold has been developed which coupled species transport with fluid flow, heat transfer and solidification. The model was applied to characterize the interfacial reaction and composition distribution of mold flux during the casting process. The model predictions were validated by comparison with experimental and plant measurements. The results show that the mold flux is driven by the surface flow of molten steel to form a high-speed circulating flow zone of mold flux at a distance 110 to 220 mm away from the mold’s narrow face, in which the reaction rate is high because of the fast interface update, which increases the time for the reaction with the molten steel and the components’ diffusion in the liquid flux pool. The mold flux near the nozzle flows slowly, allowing more time for interfacial reaction and component diffusion. The concentration of MnO in the molten flux pool decreases from the nozzle to the narrow face of the mold. The solid flux film is formed by the mixing and solidification of liquid mold fluxes with different MnO accumulations in different reaction stages, so that the MnO concentration in the solid film is lower than that of the liquid mold flux. The model predictions provide a basis for explaining the difference in composition of the mold flux film in the continuous casting of medium Mn steel.

Similar content being viewed by others

References

K. Blazek, H. Yin, G. Skoczylas, M. McClymonds, and M. Frazee: Iron Steel Technol., 2011, vol. 8, pp. 231–40.

S. Street, K. James, N. Minor, A. Roelant, and J. Tremp: Iron Steel Technol., 2008, vol. 5, pp. 38–49.

M. Kim, M. Park, S. Kang, J. Park, and Y. Kang: ISIJ Int., 2018, vol. 58, pp. 686–95.

J. Yang and M. Zhu: ISIJ Int., 2016, vol. 56, pp. 2191–8.

M.A. Rhamdhani, K.S. Coley, and G.A. Brooks: Metall. Mater. Trans. B., 2005, vol. 36B, pp. 219–27.

D.J. Kim and J.H. Park: Metall. Mater. Trans. B., 2012, vol. 43B, pp. 875–86.

X. Yu, G.-H. Wen, P. Tang, F.-J. Ma, and H. Wang: J. Iron Steel Res. Int., 2011, vol. 18, pp. 20–5.

Q. Wang, S. Qiu, and P. Zhao: Metall. Mater. Trans. B., 2012, vol. 43B, pp. 424–30.

M. Kim, S. Lee, J. Cho, M. Park, H. Lee, and Y. Kang: Metall. Mater. Trans. B., 2013, vol. 44B, pp. 299–308.

T. Wu, S. He, L. Zhu, and Q. Wang: Mate. Trans., 2016, vol. 57, pp. 58–63.

J. Yang, D. Chen, and M. Zhu: J. Iron Steel Res. Int., 2020, vol. 27, pp. 788–95.

Y. Kang, M. Kim, S. Lee, J. Cho, M. Park, and H. Lee: Metall. Mater. Trans. B., 2013, vol. 44B, pp. 309–16.

M. Kim and Y. Kang: Calphad., 2018, vol. 61, pp. 105–15.

S. He, Q. Wang, J. Zeng, M. Zhang, and B. Xie: J. Iron Steel Res. Int., 2009, vol. 12, pp. 59–65.

G. Kim, C. Kim, and I. Sohn: ISIJ Int., 2013, vol. 53, pp. 170–6.

W. Wang, K. Blazek, and A. Cramb: Metall. Mater. Trans. B., 2008, vol. 39B, pp. 66–74.

J. Cho, K. Blazek, M. Frazee, H. Yin, J. Park, and S. Moon: ISIJ Int., 2013, vol. 53, pp. 62–70.

C. Shi, M. Seo, J. Cho, and S. Kim: Metall. Mater. Trans. B., 2014, vol. 45B, pp. 1081–97.

X. Fu, G. Wen, P. Tang, Q. Liu, and Z. Zhou: Ironmak. Steelmak., 2014, vol. 41, pp. 342–9.

W. Yan, W. Chen, Y. Yang, C. Lippold, and A. Mclean: ISIJ Int., 2015, vol. 55, pp. 1000–9.

J. Li, Q. Shu, X. Hou, and K. Chou: ISIJ Int., 2015, vol. 55, pp. 830–6.

D. Xiao, W. Wang, B. Lu, and X. Zhang: Metall. Mater. Trans. B., 2016, vol. 47B, pp. 263–70.

J. Yang, H. Cui, J. Zhang, O. Ostrovski, C. Zhang, and D. Cai: Metall. Mater. Trans. B., 2019, vol. 50B, pp. 2636–46.

D. Zheng, C. Shi, Z. Li, J. Li, and J. Cho: J. Iron Steel Res. Int., 2020, vol. 27, pp. 33–41.

J. Cho, S. Yoo, M. Park, J. Park, and K. Moon: Metall. Mater. Trans. B., 2017, vol. 48B, pp. 187–96.

J. Yang, Z. Cai, D. Chen, and M. Zhu: Metall. Mater. Trans. B., 2019, vol. 50B, pp. 1104–13.

J. Yang, Z. Cai, and M. Zhu: ISIJ Int., 2018, vol. 58, pp. 299–308.

F. Calderon, N. Sano, and Y. Matsushita: Metall. Mater. Trans. B., 1971, vol. 2B, pp. 3325–32.

Y. Ukyo and K. Goto: Tetsu-to-Hagane., 1982, vol. 68, pp. 1981–6.

H. Keller, K. Schwerdtfeger, and K. Hennesen: Metall. Mater. Trans. B., 1979, vol. 10B, pp. 551–4.

A.C. Mikrovas, S.A. Argyropoulos, and I.D. Sommerville: Iron Steelmaker., 1991, vol. 18, pp. 51–61.

R. Eriksson and S. Seetharaman: Metall. Meter. Trans. B., 2004, vol. 35B, pp. 461–9.

Acknowledgments

The authors are especially grateful to the Major Program of Liaoning Province (Grant No. 2020JH1/10100001) and the National Natural Science Foundation of China (Grant Nos. 51904046, 52174317).

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yang, J., Wang, L., Li, Y. et al. Modeling of Flux Reaction and Mixing in Continuous Casting Mold of Medium Mn Steel. Metall Mater Trans B 53, 1516–1525 (2022). https://doi.org/10.1007/s11663-022-02461-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-022-02461-1