Abstract

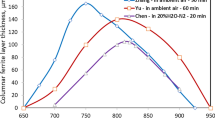

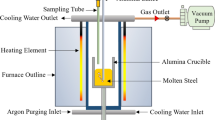

The feasibility of vacuum degassing to remove nitrogen from 3rd Generation Advanced High Strength Steel (AHSS) has been evaluated. AHSS has high Al, Si, and Mn concentrations relative to aluminum-killed steel. The feasibility of nitrogen removal has been evaluated by collating thermodynamic information, collating and measuring interfacial kinetics, and combining these in a tank degasser model. Compared with low-carbon steel, the high alloy content in 3rd Generation AHSS changes nitrogen removal by tank degassing, through effects on both the interfacial reaction rate constant (kN) and the activity coefficient of dissolved nitrogen (fN). The isotope exchange technique (15N to 14N exchange reaction) was applied to measure the interfacial nitrogen reaction rate constant for compositions in the Fe-Si and Fe-Si-Mn systems. For Fe-Si alloys, the nitrogen reaction rate constant decreases slightly with the increased Si levels: from 2.3 × 10−5 to 1.9 × 10−5 mol cm−2 s−1 atm−1 (1.5 wt pct Si), and to 1.4 × 10−5 mol cm−2 s−1 atm−1 (2.5 wt pct Si), at 1650 °C. The calculated activation energy increases from 144 to 147 kJ/mol (1.5 wt pct Si) and finally to 153 kJ/mol (2.5 wt pct Si). For Fe-Si-Mn alloys, the influence of Mn on the interfacial reaction rate constant (at constant Si) is not obvious. By using the measured interfacial rate constant in the tank degasser model, the effects of steel composition have been evaluated and the rate-limiting steps in nitrogen removal assessed.

Similar content being viewed by others

References

T. Nagasaka, R.J. Fruehan, and A.W. Cramb: ISSTech 2003 Proc. Association for Iron and Steel Technology, April 27–30, 2003, pp. 979–92.

T. Fuwa, S. Ban-ya, and T. Shinohara: Tetsu-To-Hagane, 1967, vol. 53, p. S328.

S. Ban-ya, T. Shinohara, H. Tozaki, and T. Fuwa: Tetsu-To-Hagane, 1974, vol. 60, pp. 1443–53.

M. Byrne and G.R. Belton: Metall. Trans. B, 1983, vol. 14, pp. 441–9.

P.C. Glaws and F.J. Fruehan: Metall Trans. B, 1985, vol. 16(9), pp. 551–9.

P.C. Glaws and R.J. Fruehan: Metall. Trans. B, 1986, vol. 17, pp. 317–22.

H. Ono, K. Morita, and N. Sano: Metall. Trans. B, 1995, vol. 26, pp. 991–5.

H. Ono, K. Iuchi, K. Morita, and N. Sano: ISIJ Int., 1996, vol. 36(10), pp. 1245–9.

H. Ono, H. Fukagawa, K. Morita, and N. Sano: Metall. Trans. B, 1996, vol. 27, pp. 848–53.

K. Morita, T. Hirosumi, and N. Sano: Metall Mater. Trans. B. 2000, vol. 31(10), pp. 899–904.

J. Lee and K. Morita: ISIJ Int., 2003, vol. 43(1), pp. 14–9.

S.M. Han, J.H. Park, S.M. Jung, J.H. Park, and D.J. Min: ISIJ Int., 2009, vol. 49(4), pp. 487–94.

D. Tang and P.C. Pistorius: Metall Mater. Trans. B, 2021, vol. 52(1), pp. 51–8.

M. Zhong, D. Tang, B.A. Webler, and P.C. Pistorius: Metall Mater. Trans. B, 2021, vol. 52(2), pp. 594–7.

W.T. Lankford, N.L. Samways, R.F. Craven and H.E. McGannon: The Making, Shaping and Treating of Steel, 10th ed., Assn of Iron & Steel Engineers, Pittsburgh, 1985, p. 677.

N. Bannenberg, B. Bergmann, and H. Gaye: Steel Res., 1992, vol. 10, pp. 421–37.

N. Bannenberg, H. Lachmund, B. Prothmann: 1994 Steelmaking Conference Proc., March 20–23, 1994, Chicago, USA, Iron and Steel Society, 1994, pp. 135–143.

H. Saito, A. Yoshizawa, and T. Soma: Tetsu-to-Hagane, 1984, vol. 70(1), pp. 58–64.

J.M. Jang, M.K. Paek, and J.J. Pak: ISIJ Int., 2017, vol. 57(10), pp. 1821–30.

D. Tang: Ph.D. Thesis, Carnegie Mellon University, Pittsburgh, 2019.

C.W. Bale, E. Belisle, P. Chartrand, S.A. Decterov, G. Eriksson, A.E. Gheribi, K. Hack, I.H. Jung, Y.B. Kang, J. Melancon, A.D. Pelton, S. Peterson, C. Robelin, J. Sangster, P. Spencer, and M.A. Van Ende: Calphad., 2016, vol. 54, pp. 35–53.

G. Ebneth and W. Pluschkell: Steel Res., 1985, vol. 56(10), pp. 513–8.

A. Ishii, M. Tate, T. Ebisawa, and K. Kawakami: Ironmak. Steelmak., 1983, vol. 10, pp. 35–41.

P.C. Pistorius: Treatise on Process Metallurgy, 1st edn. Elsevier, Boston, 2014, pp. 179–95.

A. Alexiadis, P. Gardin, and J. Domgin: Metall. Mater. Trans. B, 2004, vol. 35, pp. 949–56.

D. Senk, K. Christmann, S. Geimer, and D. Rzehak: Steel Res, 2016, vol. 87(1), pp. 107–11.

H. Ono, T. Koyama, and T. Usui: ISIJ Int., 2003, vol. 43(3), pp. 298–303.

H. Ono, Y. Dohi, D. Yamada, and T. Usui: ISIJ Int., 2006, vol. 46(9), pp. 1306–11.

J.M. Jang, D.H. Kim, M.K. Paek, and J.J. Pak: ISIJ Int., 2018, vol. 58(7), pp. 1185–90.

J.M. Jang, S.H. Seo, Y.D. Kim, H.J. An, and J.J. Pak: ISIJ Int., 2014, vol. 54(7), pp. 1578–83.

K. Krishnapisharody and G.A. Irons: Metall Mater. Trans. B, 2015, vol. 38(6), pp. 191–8.

R.J. Fruehan, D. Goldstein, B. Sarma, S.R. Story, P.C. Glaws, and H.U. Pasewicz: Metall Mater. Trans. B, 2000, vol. 31(10), pp. 891–8.

Acknowledgments

Support of this work by the industrial members of the Center for Iron and Steelmaking Research is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

List of symbols and abbreviations

- A :

-

Interfacial area (m2)

- [wt pct A]:

-

Mass percentage of elements in the liquid steel

- (wt pct A):

-

Mass percentage of elements in slag

- D :

-

Diffusivity (m2/s) \( D_{{{\text{Mn}}}} = 1.8 \times 10^{{ - 7}} \exp \left( {\frac{{ - 6500}}{{T_{{\text{m}}} }}} \right) \)[12]\( \log D_{{\text{N}}} = - \frac{{3800}}{{T_{{\text{m}}} }} - 6.01 \)[26]

- d :

-

Diameter (m)

- \( e_{{\text{N}}}^{i} \) :

-

First order interaction parameters between N and element i, with the reference of 1 wt pct; Values listed in Table III.

- \({f}_{\rm{N}}\) :

-

Activity coefficient of N;

- g :

-

Gravity constant: g = 9.81 (m/s2)

- H :

-

Height or pressure height (m)

- \( k^{\prime}_{{\text{S}}} \) :

-

Equivalent sulfur mass transfer coefficient (m s−1) \( k^{\prime} = \frac{{k_{{\text{S}}}^{{{\text{eff}}}} \rho _{{\text{m}}} A}}{{W_{{\text{m}}} }}\left( {1 + \frac{{W_{{\text{m}}} }}{{W_{{\text{s}}} L_{{\text{S}}} }}} \right);{\text{Where}}\;k_{{\text{S}}}^{{{\text{eff}}}} = \frac{1}{{\frac{1}{{k_{{\text{S}}}^{{\text{m}}} }} + \frac{1}{{k_{{\text{S}}}^{{\text{s}}} }}\frac{{\rho _{{\text{m}}} }}{{\rho _{{\text{s}}} L_{{\text{S}}} }}}} \)

- \({k}_{\rm{S}}^{\rm{m}}\) :

-

Sulfur liquid steel mass transfer coefficient to slag (m/s) 0.018 m/s,[15] for three plumes (flow rate 0.6 Nm3/min) 0.012 m/s,[15] for two plumes (flow rate 0.6 Nm3/min) 0.006 m/s,[15] for two plumes (flow rate 0.3 Nm2/min) equal to \(10{k}_{\rm{S}}^{\rm{s}}\)

- \({k}_{\rm{N}}^{\rm{m}}\) :

-

N liquid steel mass transfer coefficient inside the plume (m/s)

- \({k}_{\rm{M}\rm{n}}^{\rm{m}}\) :

-

Mn liquid steel mass transfer coefficient inside the plume (m/s)

- \({k}_{\rm{M}\rm{n}}^{v}\) :

-

Mn evaporation rate constant: \( k_{{{\text{Mn}}}}^{v} = \frac{{101325}}{{\sqrt {2\pi M_{{{\text{Mn}}}} {\text{RT}}} }} \)(mol m−2 s−1 atm−1); MMn = 0.055 kg/mol and R = 8.314 J mol−1 K−1

- \({k}^{\rm{a}}\) :

-

Apparent interfacial reaction rate constant between gaseous nitrogen and liquid metal (mol cm-2 s-1 atm-1)

- \({k}^{\rm{c}}\) :

-

N dissociation rate constant at the bubble-steel interface (mol cm−2 s−1 atm−1)

- K Mn :

-

Equilibrium constant for \([\rm{M}\rm{n}]\leftrightarrow \rm{M}{\rm{n}}_{\rm{g}}\)

- K N :

-

Equilibrium constant for \(\frac{1}{2}{\rm{N}}_{2}\leftrightarrow [\rm{N}]\) (partial pressure of N2 in atm; concentration of [N] in mass pct);\( \log K_{{\text{N}}} = - \frac{{518}}{{T_{{\text{m}}} }} - 1.063~\left[ {26} \right] \)

- L S :

-

Equilibrium slag-metal sulfur distribution ratio; 2512 for AHSS, 577 for low-carbon aluminum-killed steel[21]

- \({{M}}_{i} \) :

-

Molar mass of species i (kg/mol)

- P :

-

Partial pressure (atm)

- Q :

-

Argon flow rate (m3/s)

- R :

-

Radius of the plume (m)

- \({r}_{\rm{N}}^{i}\) :

-

Second order interaction parameters between N and element i, with the reference of 1 wt pct

- T :

-

Temperature (K)

- \({u}\) :

-

Argon bubble rising rate (m/s)

- V :

-

Volume (m3)

Greek symbols

- α :

-

Void fraction of the plume

- ε :

-

Energy dissipation rate (W/kg or m2/s3)

- ρ :

-

Density (kg/m3)

- σ :

-

Surface tension (N/m)

Subscripts and superscripts

- b :

-

Bubble

- i :

-

Interfacial

- t :

-

Time

- m :

-

Liquid metal

- sv:

-

Superficial velocity

- p :

-

Plume

- v :

-

Vapor

- z :

-

At the vertical coordinate z

- at:

-

Atmosphere

- std:

-

Standard condition (1 atm, 273.15 K)

- eq:

-

Equilibrium

Rights and permissions

About this article

Cite this article

Tang, D., Pistorius, P.C. Kinetics of Nitrogen Removal from Liquid Third Generation Advanced High-Strength Steel by Tank Degassing. Metall Mater Trans B 53, 1383–1395 (2022). https://doi.org/10.1007/s11663-021-02417-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-021-02417-x