Abstract

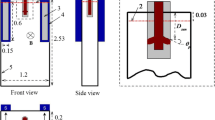

A novel type of freestanding and adjustable electromagnetic braking system (FAC-EMBr) is introduced. It consists of two pairs of vertical magnetic poles (VMPs) located near the narrow face of the mold and one pair of horizontal magnetic poles (HMPs) located below the submergence entry nozzle (SEN). The effect of the width (W) and position (D) of the VMPs on the molten steel flow behavior and meniscus fluctuation was studies by numerical simulation. The results showed that the applied FAC-EMBr could form a uniform magnetic field in the flow domain of molten steel. The magnetic flux density in the region covered by VMPs was strengthened with the increase of the width (W). The employed FAC-EMBr was found effective to weaken the interference of casting jet by reducing the flow velocity of molten steel in upward backflow and meniscus region and stabilizing the meniscus fluctuation for the two times of the “brake effect” of the vertical and horizontal magnetic field. Increasing the width of the VMPs and decreasing the distance of the VMPs were demonstrated to be meaningful to reduce the surface velocity and stabilize the meniscus fluctuation while current intensity was maintained unchanged.

Similar content being viewed by others

Change history

26 January 2022

A Correction to this paper has been published: https://doi.org/10.1007/s11663-022-02452-2

References

Y. Li, X.H. Zhang, P. Lan, and J.Q. Zhang: Int. J. Miner. Metall. Mater., 2013, vol. 20(2), pp. 138–45.

Y.J. Zhang, G.J. Xu, G.L. Jia, G.W. Yu, Y.Y. Gao, and J.C. He: J. Northeast Univ., 2000, vol. 21(2), pp. 191–94.

I. Calderón-Ramos, R.D. Morales, R. Servín-Castañeda, A. Pérez-Alvarado, S. García-Hernández, J.D.J. Barreto, and S.A. Arreola-villa: ISIJ Int., 2019, vol. 59(1), pp. 76–85.

I. Calderon-Ramos, R.D. Morales, and M. Salazar-Campoy: Steel Res. Int., 2015, vol. 86(12), pp. 1610–21.

R. Liu, K. Blazek, B. Forman, C. Fritz, and C. Graham: Steel Res. Int., 2019, https://doi.org/10.1002/srin.201800398.

S.M. Cho, B.G. Thomas, and S.H. Kim: Metall. Mater. Trans. B, 2019, vol. 50B, pp. 52–76.

W.H. Lee and K.W. Yi: Met. Mater. Int., 2020, https://doi.org/10.1007/s12540-020-00813-7.

R. Chaudhary, G.G. Lee, B.G. Thomas, and S.H. Kim: Metall. Mater. Trans. B, 2008, vol. 39B, pp. 870–84.

S. Sarkar, V. Singh, S.K. Ajmani, R. Ranjan, and K. Rajasekar: ISIJ Int., 2016, vol. 56(12), pp. 2181–90.

Q.Y. Zhang and X.H. Wang: J. Iron. Steel Res. Int., 2010, vol. 17(8), pp. 15–19.

Z.Q. Liu, B.K. Li, M.F. Jiang, and F. Tsukihashi: ISIJ Int., 2014, vol. 54(6), pp. 1314–23.

P.S. Srinivas, A. Singh, J.M. Korath, and A.K. Jana: ISIJ Int., 2017, vol. 57(9), pp. 1553–62.

R. Sánchez-pérez, R.D. Morales, L. García-demedices, J. P. Ramosand, M. DÍaz-cruz: Metall. Mater. Trans. B, 2004, vol. 35B, pp. 85–99.

Z. Li, E.G. Wang, L.T. Zhang, Y. Xu, and A.Y. Deng: Metall. Mater. Trans. B, 2017, vol. 48B, pp. 2389–2402.

Z. Li, L.T. Zhang, D.Z. Ma, and E.G. Wang: Metall. Mater. Trans. B, 2020, vol. 51B, pp. 2609–27.

Z. Li, E.G. Wang, and Y. Xu: J. Iron. Steel Res. Int., 2018, vol. 25, pp. 366–77.

A. Lehnman, G. Tallback, and A. Rullgard: ABB Rev., 1996, vol. 1, pp. 4–10.

K. Timmel, S. Eckert, and G. Gerbeth: Metall. Mater. Trans. B, 2011, vol. 42B, pp. 68–80.

D. Schurmann, I. Glavinic, B. Willers, K. Timmel, and S. Eckert: Metall. Mater. Trans. B, 2020, vol. 51B, pp. 61–78.

S. Kollberg and P. Lofgren: Rev. Metall.-Paris, 2005, vol. 102(6), pp. 431–40.

X.C. Miao, K. Timmel, D. Lucas, Z.M. Ren, S. Eckert, and G. Gerbeth: Metall. Mater. Trans. B, 2012, vol. 43B, pp. 954–72.

B.K. Li, T. Okane, and T. Umeda: Metall. Mater. Trans. B, 2000, vol. 31B, pp. 1491–1503.

A. Vakhrushev, A. Kharicha, Z.Q. Liu, M.H. Wu, A. Ludwig, G. Nitzl, Y. Tang, G. Hackl, and J. Watzinger: Metall. Mater. Trans. B, 2020, vol. 51B, pp. 2811–28.

A. Vakhrushev, A. Kharicha, E. Karimi-Sibaki, M.H. Wu, A. Ludwig, G. Nitzl, Y. Tang, G. Hackl, J. Watzinger, and S. Eckert: Metall. Mater. Trans. B, 2021, vol. 52B, pp. 3193–3207.

S. Garcia-Hernandez, C. H. Gonzalez-Guzman, R. Morales Davila, J.D.J. Barreto, E. Gutierrez and I. Calderon-Ramos: Crystals, 2020, vol. 10(11), p. 958.

Y.B. Yin, J.M. Zhang, H.T. Ma, and Q.H. Zhou: Steel Res. Int., 2021, https://doi.org/10.1002/srin.202000582.

S.M. Cho and B.G. Thomas: JOM, 2020, vol. 72(10), pp. 3610–27.

Y. Wang, Z.Q. Zhang, Z. Yu, H. Jia, K. Deng, Z.S. Lei, and Z.M. Ren: Acta Metall. Sin., 2011, vol. 47(10), pp. 1285–91.

F. Li, E.G. Wang, M.J. Feng, and Z. Li: ISIJ Int., 2015, vol. 55(4), pp. 814–20.

L. Xu, E.G. Wang, C. Karcher, A.Y. Deng, and X.J. Xu: Metall. Mater. Trans. B, 2018, vol. 49B, pp. 2779–93.

F. Li, E.G. Wang, and M.J. Feng: Metall. Ital., 2016, vol. 7, pp. 17–25.

M. Sedén, N. Jacobson, A. Lehman and J.E. Eriksson: Proceedings of the 8th European Continuous Casting Conference, Graz, Austria, 23–26 June 2014.

S.W. Han, H.J. Cho, S.Y. Jin, M. Seden, I.B. Lee, and I. Sohn: Metall. Mater. Trans. B, 2018, vol. 49B, pp. 2757–69.

S. Kunstreich, T. Gautreau, J. Y. Ren, A. Codutti, F. Guastini, and M. Petronio: Proceedings of the 8th European Continuous Casting Conference, Graz, Austria, 23–26 June 2014.

B. Mao, J.M. Tao, J.Z. Li, and L.J. Sun: Contin. Cast., 2006, vol. 6, pp. 32–37.

R. Chaudhary, B.G. Thomas, and S.P. Vanka: Metall. Mater. Trans. B, 2012, vol. 43B, pp. 532–53.

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (Nos. 51804154, 51574083, U1760206), the College and University Scientific Research Projects in Liaoning Province (No. L2020023) and the 111 Project 2.0 of China (No. BP0719037).

Conflict of interest

The authors declare no conflict of interest.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this article was revised: Figure 2a was corrected.

Rights and permissions

About this article

Cite this article

Li, Z., Zhang, L., Bao, Y. et al. Influence of the Vertical Pole Parameters on Molten Steel Flow and Meniscus Behavior in a FAC-EMBr Controlled Mold. Metall Mater Trans B 53, 938–953 (2022). https://doi.org/10.1007/s11663-021-02416-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-021-02416-y