Abstract

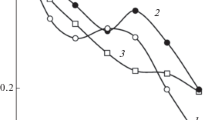

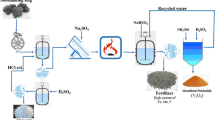

This article describes one of the solutions to the problem associated with the utilization of metallurgical wastes and presents a high-efficiency method for recycling a large amount of vanadium-containing BOF slag with heap leaching by sulfuric acid. The leaching degree of vanadium from vanadium-containing BOF slag was 98.5 pct by agitation leaching and 71 pct by leaching in a percolator column. The diffusion through the slag boundary layer is a limiting factor that determines the vanadium leaching efficiency. The authors carried out the experiment to determine the time required for the solution to diffuse into the vanadium-containing BOF slag. In this article, the authors determined the influence of the pause duration between irrigations of slag in the percolator column. The slag, both before leaching and after, was tested using the one-stage batch test and the standard toxicity characteristic leaching procedure extraction test to compare their leachate capacity in relation to vanadium. The composition and structural features of vanadium-containing BOF slag were investigated by X-ray diffraction, scanning electron microscopy, and an energy-dispersive x-ray analysis console. According to these data, vanadium is present in all phases of the slag in different concentrations. The process of heap leaching carried out in a percolation column in the laboratory-scale experiment can be considered selective, since the leaching degree of vanadium is higher than the leaching degree of other slag components, except for aluminum.

Graphical Abstract

Similar content being viewed by others

References

R.R. Moskalyk and A.M. Alfantazi: Miner. Eng., 2003, 16, vol. 16.

T. Itoh, T. Kanno, A. Ikeuchi, K. Kawai, T. Hara, and N. Tokuda: SAE Tech. Pap., 1999, pp. 130–5.

P. Ning, X. Lin, X. Wang, and H. Cao: Chem. Eng. J., 2016, vol. 301, pp. 132–8.

M. Imtiaz, M.S. Rizwan, S. Xiong, H. Li, M. Ashraf, S.M. Shahzad, M. Shahzad, M. Rizwan, and S. Tu: Environ. Int., 2015, vol. 80, pp. 79–88.

A. Bhatnagar, A.K. Minocha, D. Pudasainee, H.K. Chung, S.H. Kim, H.S. Kim, G. Lee, B. Min, and B.H. Jeon: Chem. Eng. J., 2008, vol. 144, pp. 197–204.

K. Lundkvist, M. Brämming, M. Larsson, and C. Samuelsson: J. Clean. Prod., 2013, vol. 47, pp. 43–51.

Feature, 2007.

X.S. Li and B. Xie: Int. J. Miner. Metall. Mater., 2012, vol. 19, pp. 595–601.

Y. Wei, L. Du, X. Deng, X. Liu, X. Mei, and D. Shi: Chem. Eng. J., 2018, vol. 354, pp. 53–61.

Z. Zhao, L. Cui, Y. Guo, H. Li, and F. Cheng: Chem. Eng. J., 2020, vol. 381, p. 122699.

K. Meschke, R. Hofmann, R. Haseneder, and J.U. Repke: Chem. Eng. J., 2020, vol. 380, p. 122476.

M. Aarabi-Karasgani, F. Rashchi, N. Mostoufi, and E. Vahidi: Hydrometallurgy., 2010, vol. 102, pp. 14–21.

Z. Yang, H.Y. Li, X.C. Yin, Z.M. Yan, X.M. Yan, and B. Xie: Int. J. Miner. Process., 2014, vol. 133, pp. 105–11.

J. Xiang, Q. Huang, X. Lv, and C. Bai: J. Clean. Prod., 2018, vol. 170, pp. 1089–101.

X. Zhu, Y. Zhang, J. Huang, T. Liu, and Y. Wang: Int. J. Miner. Process., 2012, vol. 114–117, pp. 1–6.

A. Kovalev, D. Wainstein, V. Vakhrushev, A. Volkov, and U. Kologrieva: Materials., 2019, https://doi.org/10.3390/ma12213578.

H.M. Rietveld: J. Appl. Crystallogr., 1969, vol. 2, pp. 65–71.

H.Y. Li, K. Wang, W.H. Hua, Z. Yang, W. Zhou, and B. Xie: Hydrometallurgy., 2016, vol. 160, pp. 18–25.

M. Goto, B.C. Roy, and T. Hirose: J. Supercrit. Fluids., 1996, vol. 9, pp. 128–33.

D.P. Ordinartsev, A.V. Sviridov, S.S. Naboichenko, and V.V. Yurchenko: Metallurgist., 2018, https://doi.org/10.1007/s11015-018-0586-1.

W. Li, Y. Zhang, T. Liu, J. Huang, and Y. Wang: Hydrometallurgy., 2013, vol. 131–132, pp. 1–7.

E.M. Rabinovitch, V.G. Mizin, M.E. Rabinovitch, T.P. Sirina, T.I. Krasnenko, 2005. Ekaterinburg: UB RAS

H. Peng: J. Environ. Chem. Eng., 2019, vol. 7, p. 103313.

Acknowledgments

The work was carried out according to the state assignment for IMET UB RAS using the equipment of the Collaborative Usage Center “Ural-M.” The author also thanks Dr. B.D. Khalezov for a very helpful discussion of the heap leaching method.

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted June 7, 2021; accessed November 24, 2021.

Rights and permissions

About this article

Cite this article

Ordinartsev, D., Krasheninin, A., Petrova, S. et al. Recycling of Vanadium-Containing BOF Slag with Agitation and Heap Leaching. Metall Mater Trans B 53, 1162–1172 (2022). https://doi.org/10.1007/s11663-021-02408-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-021-02408-y