Abstract

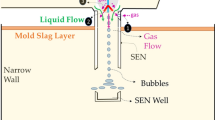

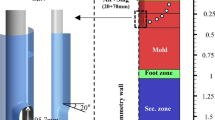

Argon gas injection into a continuous casting mold facilitates many factors related to smooth and long casting sequences by reducing nozzle clogging, improvements in steel cleanliness by inclusion floatation, etc. However, an unoptimized gas flow rate may deteriorate the cast slab quality through mold slag exposure, slag entrapment into the solidifying shell, etc. Formation of mold slag open eyes (MSOE) removes the protective slag layer to invite the issue of liquid steel reoxidation. Different MSOE formations were observed at varying flow conditions through physical modeling experiments. Total MSOE area helps in determining the extent of reoxidation. This study aims to predict the dimensionless MSOE area by developing a macroscopic mechanistic model which results in a model equation in terms of a “densimetric Froude number (FrD,m)” and two unknown arbitrary constants. To close this equation, FrD,m is obtained by evaluating its unknown characteristic, i.e., mold plume velocity (Ump). It was calculated at different gas flow rates (Qg) using shadow-imaging technique applied on a 1:7 scale water model. Average velocity of bubbles (approximated as Ump) in plume was estimated by individual bubble tracking using an ImageJ macro validated against the manually calculated Ump. Then, FrD,m was calculated using both manual and automatic Ump values. In separate water modeling experiments, total MSOE areas at same Qg values were obtained. Then, dimensionless MSOE area was calculated by dividing this total MSOE area by total plume area. Dimensionless area was correlated with manual and automatic FrD,m. This correlation is compared with the model equation, and arbitrary constants were obtained to close the model equation. Finally, a zone-wise mean bubble size analysis was introduced to strengthen the assumption regarding the probable location of MSOE.

Zhongqiu Liu, Baokuan Li, Alexander Vakhrushev, Menghuai Wu, and Andreas Ludwig, Physical and Numerical Modeling of Exposed Slag Eye in Continuous Casting Mold using Euler–Euler Approach, steel research int. 2019, 90, 1800117, Copyright Wiley-VCH GmbH. Reproduced with permission

Similar content being viewed by others

Abbreviations

- A mp :

-

Area of mold plume

- A ms :

-

Area of mold slag open eye (MSOE)

- P a :

-

Pressure of control volume from top

- P b :

-

Pressure of control volume from bottom

- j :

-

Unit vector in the y direction

- N :

-

Unit normal vector

- G :

-

Gravitational acceleration

- U o :

-

Velocity of downward flow in control volume (mm/s)

- U i :

-

Horizontal velocity of liquid steel in control volume (mm/s)

- U mp :

-

Mold plume velocity (mm/s)

- T :

-

Time bubble spent in changing its position

- V I :

-

Indicative gas volume in zone 1

- V II :

-

Indicative gas volume in zone 2

- V III :

-

Indicative gas volume in zone 3

- V T :

-

Total indicative gas volume

- Θ :

-

Angle of downward flow from vertical

- W LS :

-

Weight of liquid steel in control volume

- W ms :

-

Weight of mold slag in control volume

- ρ LS :

-

Density of liquid steel

- ρ ms :

-

Density of the mold slag

- h :

-

Height of slag in control volume

- v x :

-

Velocity of bubble in x-direction

- v y :

-

Velocity of bubble in y-direction

- Δx :

-

Change in position of bubble in x-direction

- Δy :

-

Change in position of bubble in y-direction

- λ :

-

Model scale factor

- L m :

-

Characteristic length of the model

- L p :

-

Characteristic length of the prototype

- ρ Ar ,1550 °C :

-

Density of argon at 1550 °C

- ρ Ar ,25 °C :

-

Density of argon at 25 °C

- ρ Air ,25 °C :

-

Density of air at 25 °C

- ρ steel, 1550 °C :

-

Density of liquid steel at 1550 °C

- ρ water ,25 °C :

-

Density of water at 25 °C

- v Ar,1550 °C :

-

Velocity of Ar at 1550 °C

- v Air,25 °C :

-

Velocity of Air at 25 °C

- Q Ar,1550 °C :

-

Gas flow rate of argon at 1550 °C

- Q Ar,25 °C :

-

Gas flow rate of argon at 25 °C

- Q Air,25 °C :

-

Gas flow rate of air at 25 °C

- Q l,m :

-

Liquid flow rate for model

- Q l,p :

-

Liquid flow rate for prototype

- T Ar,1550 °C :

-

Temperature of argon at 1550 °C

- T Ar,25 °C :

-

Temperature of argon at 25 °C

- Fr D,m :

-

Densimetric Froude number

- \({A}_{\text{ms}}^{T}\) :

-

Total MSOE area

- \({A}_{\text{ms}}^{D}\) :

-

Dimensionless MSOE area

- U p :

-

Plume velocity

- M :

-

Final position of the bubble

- N :

-

Track number

References

Ergolines lab s.r.l, MPF, automatic mold powder, feeder system for billet, bloom and slab casters, https://www.ergolines.it/products/mpf/?str=1

S. Pendleton, Mold Powder Feeder, 2007, Google Patents, US20070034642A1,

H. Nakajima, Powder feeder in continuous casting, 1991, Google Patents, US5067553A

Z. Liu, Z. Sun, and B. Li: Metall. Mater. Trans. B., 2017, vol. 48B, pp. 1248–67.

Z. Liu, B. Li, M. Jiang, and F. Tsukihashi: ISIJ Int., 2013, vol. 53(3), pp. 484–92.

H. Tanaka, H. Kuatori, and R. Nishihara: Tetsu-to-Hagane., 1992, vol. 78, pp. 761–6.

G. Reiter and K. Schwerdtfeger: ISIJ Int., 1992, vol. 32, pp. 57–65.

X. Li, B. Li, Z. Liu, R. Niu, Y. Liu, C. Zhao, C. Huan, H. Qiao, and T. Yuan: Metals., 2019, vol. 9, p. 7.

Z. Liu, B. Li, A. Vakhrushev, M. Wu, and A. Ludwig: Steel Res. Int., 2019, vol. 90, p. 1800117.

K. Yonezawa and K. Schwerdtfeger: Metall. Mater. Trans. B., 1999, vol. 30B, pp. 411–8.

K. Yonezawa and K. Schwerdtfeger: Metall. Mater. Trans. B., 2000, vol. 31B, pp. 461–8.

Subagyo, G.A. Brooks, and G.A. Irons: ISIJ Int., 2003, vol. 43(2), pp. 262–3.

M. Iguchi, K.I. Miyamoto, S. Yamashita, D. Iguchi, and M. Zeze: ISIJ Int., 2004, vol. 44(3), pp. 636–8.

D. Mazumdar and J.W. Evans: Metall. Mater. Trans. B., 2004, vol. 35B, pp. 400–4.

K. Krishnapisharody and G.A. Irons: Metall. Mater. Trans. B., 2006, vol. 37B, pp. 763–72.

Z.Q. Liu, L.M. Li, and B.K. Li: ISIJ Int., 2017, vol. 57, pp. 1971–9.

C.A. Llanos, S. Garcia, J.A. Ramos-Banderas, J.D.J. Barreto, and G. Solorio: ISIJ Int., 2010, vol. 50, pp. 396–402.

S.W.P. Cloete, J.J. Eksteen, and S.M. Bradshaw: Miner. Eng., 2013, vol. 46, p. 16.

H. Liu, Z. Qi, and M. Xu: Steel Res. Int., 2011, vol. 82, pp. 440–8.

L.M. Li, B.K. Li, and Z.Q. Liu: ISIJ Int., 2017, vol. 57, pp. 1980–9.

R.D. Morales, F.A.C. Hurtado, and K. Chattopadhyay: ISIJ Int., 2019, vol. 59(7), pp. 1224–33.

K. Krishnapisharody and G.A. Irons: Metall. Mater. Trans. B., 2015, vol. 46B, pp. 191–8.

E.K. Ramasetti, V.V. Visuri, P. Sulasalmi, T. Fabritius, J. Savolainen, M. Li, and L. Shao: Metals., 2019, https://doi.org/10.3390/met9101048.

K. Chattopadhyay, M. Hasan, M. Isac, and R.I.L. Guthrie: Metall. Mater. Trans. B., 2010, vol. 41B, pp. 225–33.

S. Chatterjee and K. Chattopadhyay: Metall. Mater. Trans. B., 2016, vol. 47B, pp. 3099–114.

S. Chatterjee, D. Li, and K. Chattopadhyay: Steel Res. Int., 2017, vol. 88, p. 9. https://doi.org/10.1002/srin.201600436.

B.G. Thomas, A. Dennisov and H. Bai, ISS 80th Steelmaking Conf. 1997, pp. 375–84

H. Bai and B.G. Thomas: Metall. Mater. Trans. B., 2001, vol. 32B, pp. 1143–59.

R. Sanchez-Perez, R.D. Morales, M. Diaz Cruze, O. Olivares-Xometl, and J. Palafox-Ramos: ISIJ Int., 2003, vol. 43(5), pp. 637–46.

R. Sánchez-pérez, R.D. Morales, L. García-Demedices, J. Palafox Ramos, and M. Díaz-Cruz: Metall. Mater. Trans. B., 2004, vol. 35B, p. 85.

A.R. Banderas, R.D. Morales, R. Sanchez-Perez, L. Garcia-Demedices, and G. Solorio-Diaz: Int. J. Multiphase Flow., 2005, vol. 31, pp. 643–65.

Z.Q. Liu, F.S. Qi, B.K. Li, and S.C.P. Cheung: Int. J. Multiphase Flow., 2016, vol. 79, pp. 190–201.

S.M. Cho, B.G. Thomas, and S.H. Kim: ISIJ Int., 2018, vol. 58(8), pp. 1443–52.

A. Srivastava, R. Wang, S.K. Dinda, and K. Chattopadhyay: Mach. Learn. Appl., 2021, https://doi.org/10.1016/j.mlwa.2021.100180.

F. Liu, H. Zhou, L. Zhang, C. Ren, J. Zhang, Y. Ren, and W. Chen: Steel Res. Int., 2021, https://doi.org/10.1002/srin.202100067.

O. Reynolds: The Sub-mechanics of the Universe, vol. 3, Cambridge University Press, Cambridge, 1903.

J.E. Marsden and A.J. Tromba: Vector Calculus, 5th ed. W.H. Freeman, New York, 2003.

L.G. Leal: Advanced Transport Phenomena: Fluid Mechanics and Convective Transport Processes, Cambridge University Press, Cambridge, 2007.

W. Chen, Y. Ren, L. Zhang, and P.R. Scheller: JOM., 2019, vol. 71, p. 1158. https://doi.org/10.1007/s11837-018-3255-8.

S.H. Kim, R.J. Fruehan, and R.I.L. Guthrie, in Proc. Steelmak. Conf. (1986), pp. 107–18.

M. Peranandhanthan and D. Mazumdar: ISIJ Int., 2010, vol. 50, pp. 1622–31.

M. Bielnicki and J. Jowsa: Steel Res. Int., 2018, https://doi.org/10.1002/srin.201800110.

X. Jin, D.F. Chen, X. Xie, J. Shen, and M. Long: Steel Res. Int., 2013, vol. 84, pp. 31–9.

A. Srivastava and K. Chattopadhyay: Metall. Mater. Trans. B., 2021, vol. 52B, pp. 1279–93. https://doi.org/10.1007/s11663-021-02090-0.

A. Asgarian, Z. Yang, Z. Tang, M. Bussmann, and K. Chattopadhyay: Exp. Fluids., 2020, vol. 61, p. 14. https://doi.org/10.1007/s00348-019-2847-6.

A. Srivastava, R. Wang, D. Li, K. Chattopadhyay, AISTech 2020, Proc. Iron & Steel Technol. Conf., 2020, https://doi.org/10.33313/380/085

A. Srivastava, S. K. Dinda, K. Chattopadhyay, J. Sengupta, AISTech2021, Proc. of the Iron & Steel Technol. Conf., 2021, https://doi.org/10.33313/382/172

S.K. Dinda, A. Srivastava, K. Chattopadhyay, J. Sengupta, AISTech 2021, Proc. of the iron & steel technology conference (2021), https://doi.org/10.33313/382/171

F. Tiago and W. Rasband: ImageJ User Guide IJ., 2012, vol. 1, p. 46r.

N. Stuurman and J. Schindelin, https://imagej.net/MTrack2, Accessed 29 Apr 2017

G. Ebneth and W. Pluschkell: Steel Res., 1985, vol. 56, pp. 513–23.

Acknowledgments

We acknowledge the Natural Sciences and Engineering Research Council of Canada (NSERC), the Association of Iron and Steel Technology Foundation Steel Professorship program and the Dean’s Catalyst Professorship at the University of Toronto for funding this study.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted February 15, 2021, accepted November 19, 2021.

Appendix

Appendix

ImageJ macro code for automatic measurement of bubble velocity

filepath=File.openDialog("Select a File");

dir=File.getParent(filepath);

open(filepath);

name = File.nameWithoutExtension;

run("8-bit");

setAutoThreshold("IsoData");

//run("Threshold...");

setThreshold(0, 139);

//setThreshold(0, 139);

setOption("BlackBackground", false);

run("Convert to Mask", "method=IsoData background=Light");

run("Fill Holes", "stack");

run("Watershed", "stack");

trackpara = "minimum=50 maximum=50000 maximum_=100 minimum_=1 save display show show_0 show_1 save=" + dir + File.separator + name+".csv";

run("MTrack2 ", trackpara);

Rights and permissions

About this article

Cite this article

Srivastava, A., Chattopadhyay, K. Macroscopic Mechanistic Modeling for the Prediction of Mold Slag Exposure in a Continuous Casting Mold. Metall Mater Trans B 53, 1018–1035 (2022). https://doi.org/10.1007/s11663-021-02396-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-021-02396-z