Abstract

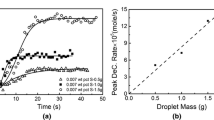

Several industrial processes, such as those in metallurgical, chemical, ceramic, and cement industries, often involve solid–solid reactions. The solid reactions at high temperatures are often limited or controlled by solid diffusion, and some models have been suggested to describe the reaction behaviors. A model considering the particle shape, surface area, particle size distribution, and diffusion rate of reactants was established to develop a quantitative representation of the solid–solid reaction of powders in a binary reactant system. In this model, the interface of particles was divided into reaction and nonreaction surfaces, and the particle shape was divided into first- and second-level shapes. The area of the reaction interface was calculated, and the concentration distribution of the reactants was numerically expressed. The simulated kinetics curves of fractional conversion α with time for different average particle sizes and diffusion coefficients were shown to be useful for evaluating the kinetics of solid–solid reactions. The simulated kinetics curves and experimental data from the references were compared, and a good accuracy was achieved.

Similar content being viewed by others

References

J.S. Sharp, G.W. Brindley, and B.M. Narahari Achar: J. Am. Ceram. Soc., 1966, vol. 49(7), pp. 379–82.

S.F. Hulbert: Br. Ceram. Soc. J., 1967, vol. 6(1), pp. 11–20.

J.D. Hancock and J.H. Sharp: J. Am. Ceram. Soc., 1972, vol. 55, pp. 74–7.

S.J. Kridelbaugh: Am. J. Sci., 1973, vol. 273, pp. 757–77.

J.H. Taplin: J. Am. Ceram. Soc., 1974, vol. 57(3), pp. 140–2.

C.H. Bamford and C.F.G. Tipper, eds.: Chemical Kinetics Reactions in Solid State, Elsevier, New York, 1980.

J.R. Frade and M. Cable: J. Am. Ceram. Soc., 1992, vol. 75(7), pp. 1949–57.

P. Argyrakis: Comput. Phys., 1992, vol. 6(5), pp. 525–8.

A. Maitre, P. Lefort, and H. Temp: Mater. Process., 2002, vol. 6, pp. 267–82.

D. Achilias and C. Piparissides: J. Appl. Polym. Sci., 1988, vol. 35, pp. 1303–23.

D. Fatu: J. Therm. Anal., 1992, vol. 38, pp. 935–41.

A.K. Suresh and C. Ghoroi: AIChe J., 2009, vol. 55(9), pp. 2399–413.

W. Jander and Z. Anorg: Allg. Chem., 1927, vol. 163, pp. 1–30.

A.M. Ginstling and B.I. Brounshtein: J. Appl. Chem. USSR (Engl. Transl.)., 1950, vol. 23, pp. 1327–38.

G. Valensi: J. Chim. Phys.-Chim Biol., 1950, vol. 47, pp. 489–505.

R.E. Charter: J. Chem. Phys., 1961, vol. 34, pp. 2010–5.

N. Ouchiyama and T. Tanaka: Ind. Eng. Chem. Fundam., 1980, vol. 19(4), pp. 338–40.

Y.J. Hao and T. Tanaka: Can. J. Chem. Eng., 1988, vol. 66, pp. 761–6.

Y.J. Hao and T. Tanaka: J. Soc. Powder Technol. Jpn., 1987, vol. 24, pp. 588–92.

Y.J. Hao and T. Tanaka: Kagahu Kogahu Ronbunshu., 1987, vol. 13, pp. 764–72.

Y.J. Hao and T. Tanaka: J. Assoc. Mater. End. Resour., 1988, vol. 1, pp. 52–8.

A. Shimizu and Y.H. Hao: J. Am. Ceram. Soc., 1997, vol. 80, pp. 557–68.

Shimizu: Powder Technol., 1998, vol. 100, pp. 24–31.

C. Ghoroi and A.K. Suresh: AIChE J., 2007, vol. 53, pp. 502–13.

C. Ghoroi and A.K. Suresh: AIChE J., 2007, vol. 53(9), pp. 2399–410.

K. Suresh and C. Ghoroi: AIChE J., 2009, vol. 55, pp. 2399–413.

R. Amaresh, M. Pathak, and A.K. Suresh: Ind. Eng. Chem. Res., 2014, vol. 53, pp. 11659–67.

M. Phutke and H. Dedhia: Chem. Eng. J., 2019, vol. 377, pp. 1–10.

P.G.Y. Huang, C.H. Lu, and T.W.H. Sheu: Mater. Sci. Eng. B., 2004, vol. 107, pp. 39–35.

P.G.Y. Huang, C.H. Lu, and T.W.H. Sheu: Mater. Sci. Eng. B., 2003, vol. 103, pp. 77–82.

S.K. Das, Y.M. Kim, T.K. Ha, and R. Gauvin: Metall. Mater. Trans. A., 2013, vol. 44A, pp. 320–2.

K. Meguro and M.O.M. Kajihara: J. Mater. Sci., 2012, vol. 47, pp. 4955–64.

Y. Tanaka and M. Kajihara: J. Mater. Sci., 2010, vol. 45, pp. 5676–84.

K. Motojima, T. Asano, W. Shinmei, and M. Kajihara: J. Electron. Mater., 2012, vol. 41, pp. 3292–302.

M. Hashiba, W. Shinmei, and M. Kajihara: J. Electron. Mater., 2011, vol. 41, pp. 32–43.

L. Gao, L. Zhou, C.S. Li, J.Q. Feng, and Y.F. Lu: J. Mater. Sci., 2013, vol. 48, pp. 974–7.

H. Fukuyama, M.K. Hossain, and K. Nagata: Metall. Mater. Trans. B., 2002, vol. 33B, pp. 257–64.

S. Tsuji: Metall. Mater. Trans. A., 2014, vol. 45A, pp. 5371–8.

R. Paulson: Z. Anorg. Allg. Chem., 1973, vol. 401, pp. 172–8.

J. Beretka and T. Brown: J. Am. Ceram. Soc., 1983, vol. 66, pp. 383–8.

P. Zhang, J.K. Baczewska, S. Du, and S. Seetharaman: Metall. Mater. Trans. A., 1996, vol. 27A, pp. 2978–84.

S. Shimada, K. Soejima, and T. Ishii: React. Solids., 1990, vol. 8, pp. 51–61.

J. Y. Xiang, X. Wang, G. S. Pei, Q. Y. Huang, X. W. Lv. Int. J. Miner. Metall. Mater., 2020

A. Shimizu and J. Saitou: Solid State Ionics., 1990, vol. 38, pp. 161–269.

L. Fresh and J.S. Dooling: J. Phys. Chem., 1966, vol. 70, pp. 3189–202.

Acknowledgments

This study was supported by the Key Fund of Natural Science (Grant No. 1902217), Chongqing Outstanding Youth Project (Grant No. CSTC2019JCYJJQX0024), and State Key Laboratory of Vanadium and Titanium Resources Comprehensive Utilization. We also thank the Chongqing Key Laboratory of Vanadium-Titanium Metallurgy and New Materials, Chongqing University, Chongqing 400044, PR China.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted December 9, 2020, accepted November 16, 2021.

Rights and permissions

About this article

Cite this article

Yang, M., Lv, X., Bai, C. et al. Isothermal Kinetics Model for Solid–Solid Reaction of Powders Through Surface Area and Size Distribution of Particles. Metall Mater Trans B 53, 968–980 (2022). https://doi.org/10.1007/s11663-021-02393-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-021-02393-2