Abstract

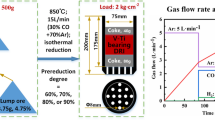

The slag foaming caused by Ti(C,N) is the main limitation of smelting vanadium–titanium magnetite by blast furnace. COREX, with unique pure oxygen injection that avoids the formation of Ti(C,N), has a huge potential advantage for the smelting of vanadium–titanium magnetite. In the present study, the detailed characterization was performed on the softening and melting behavior of V–Ti bearing burden under simulated COREX conditions. Results indicated that the added V–Ti bearing pellet (VTP) led to the increase of T10 and decreases of T40, TS and Td for mixed burden due to the generation of FeO·TiO2. Every 10 pct increase in VTP ratio reduced ΔT3 by 13.7 °C. Furthermore, the effect of VTP on burden dropping changed from inhibition (TiO2 → TiC) to promotion (\({({\mathrm{Si}}_{2}{\mathrm{O}}_{5}^{2-})}_{n}\to {({\mathrm{SiO}}_{3}^{2-})}_{n}\)) with increased VTP ratio, causing the burden dropping rate first to decrease from 70.0 to 13.5 and then increase to 96.6 pct, weakening the foaming of slag. When the VTP ratio reached 47.25 wt pct, the burden bed still had good gas permeability; its SD and PPeak caused by slag foaming were 8.06 kPa and 218.41 kPa·°C. The vanadium content in residual iron also exceeded 0.2 wt pct, the minimum requirement for extracting vanadium from molten iron.

Similar content being viewed by others

References

S. Zhang, S. Liu, W. Ma, K. Zhu, L. Cao, and Y. Dai: Present Status and Development of Comprehensive Utilization of Vanadium-Titanium Magnetite, Springer International Publishing, San Diego, CA, 2017, pp. 203–10.

P.R. Taylor, S.A. Shuey, E.E. Vidal, and J.C. Gomez: Mining. Metall. Explor., 2006, vol. 23, pp. 80–6.

B. Yang, J. He, G. Zhang, and J. Guo: Vanadium., 2021, vol. 6, pp. 123–47.

D. Chen, H. Zhao, G. Hu, T. Qi, H. Yu, G. Zhang, L. Wang, and W. Wang: J. Hazard. Mater., 2015, vol. 294, pp. 35–40.

B. Wang, X. Ding, T. Ju, X. Zhang, and G. Cheng: Metals-Basel., 2021, vol. 11, p. 16. https://doi.org/10.3390/met11010045.

Y. Sui, Y. Guo, T. Jiang, and G.Z. Qiu: J. Mater. Res. Technol., 2019, vol. 8, pp. 3036–43.

E. Hukkanen and H. Walden: Int. J. Miner. Process., 1985, vol. 15, pp. 89–102.

L. Han, W. Huang, and Y. Liu: ISIJ Int., 2016, vol. 56, pp. 1559–62.

X. Zhou and Z. Du: Advanced Technologies in Manufacturing, Engineering and Materials, Trans Tech Publications, Zurich, 2013, pp. 1430–4.

X. Zhou, Z. Shi, G. Zhang and Z. Du: Advances in Mechatronics and Control Engineering, Trans Tech Publications, Switzerland, 2014, pp. 612–15.

Y. You, Z. Luo, Z. Zou, and R. Yang: Powder Technol., 2020, vol. 361, pp. 274–82.

C. Hu, W. Han, and Y. Zhang: Adv. Mater. Res., 2010, vol. 146, pp. 853–8.

L. Jiao, S. Kuang, A. Yu, Y. Li, X. Mao, and H. Xu: Metall. Mater. Trans. B., 2020, vol. 51B, pp. 258–75.

K. Ma, J. Xu, J. Deng, D. Wang, Y. Xu, Z. Liao, C. Sun, S.F. Zhang, and L.Y. Wen: Metall. Mater. Trans. B., 2018, vol. 49B, pp. 2308–21.

X. Yu and Y. Shen: Metall. Mater. Trans. B., 2020, vol. 51B, pp. 2079–94.

W. Zhao, M. Chu, Z. Liu, H. Wang, J. Tang, and Z. Ying: Metall. Mater. Trans. B., 2019, vol. 50B, pp. 1878–95.

X. Liu, T. Honeyands, G. Evans, P. Zulli, and D. Odea: Ironmaking Steelmaking., 2018, vol. 46, pp. 953–67.

Y.Z. Pan, X.F. She, G. Wang, H.B. Zuo, J.S. Wang, and Q.G. Xue: ISIJ Int., 2019, vol. 59, pp. 1192–7.

M. Guha and M. Sinha: ISIJ Int., 2015, vol. 55, pp. 2033–5.

W.T. Guo, Q.G. Xue, Y.L. Liu, X.F. She, and J.S. Wang: Ironmaking Steelmaking., 2016, vol. 43, pp. 22–30.

A.A. Adetoro, H. Sun, S. He, Q. Zhu, and H. Li: Metall. Mater. Trans. B., 2018, vol. 49B, pp. 846–57.

K. Zhou, J.Q. Song, Z.X. You, H. Xie, and X.W. Lv: ISIJ Int., 2020, vol. 60, pp. 1409–15.

G. Cheng, X. Xue, T. Jiang, and P. Duan: Metall. Mater. Trans. B., 2016, vol. 47B, pp. 1713–26.

L. Zhang, Z. Gao, S. Yang, W. Tang, and X. Xue: Metals-Basel., 2020, vol. 10, p. 14. https://doi.org/10.3390/met10050569.

L. Zhang, S. Yang, W. Tang, and X. Xue: Minerals-Basel., 2019, vol. 9, p. 14. https://doi.org/10.3390/met9040395.

E.A. Mousa and A. Babich: ISIJ Int., 2011, vol. 51, pp. 350–8.

G. Wang, Q.G. Xue, and J.S. Wang: Ironmaking Steelmaking., 2019, vol. 46, pp. 477–84.

D.J. Gavel, Q.S. Song, A. Adema, J. van der Stel, J. Sietsma, R. Boom, and Y.X. Yang: Ironmaking Steelmaking., 2020, vol. 47, pp. 195–202.

D.J. Gavel, A. Adema, J. van der Stel, J. Sietsma, R. Boom, and Y.X. Yang: ISIJ Int., 2019, vol. 59, pp. 778–86.

D.J. Gavel, A. Adema, J. van der Stel, C. Kwakernaak, J. Sietsma, R. Boom, and Y.X. Yang: ISIJ Int., 2020, vol. 60, pp. 451–62.

W. Zhao, M. Chu, H. Wang, Z. Liu, J. Tang, and Z. Ying: ISIJ Int., 2018, vol. 58, pp. 1989–98.

H. Wang, G.B. Qiu, and Q. Deng: Metal. Int., 2012, vol. 17, pp. 22–6.

W. Zhao, M.S. Chu, H.T. Wang, Z.G. Liu, and Y.T. Tang: Int. J. Miner. Metall. Mater., 2016, vol. 23, pp. 501–10.

Z. Chang, J. Zhang, and X. Ning: Fuel., 2019, vol. 253, pp. 32–9.

H. Xie, W. Yu, Z.X. You, X.W. Lv, and C.G. Bai: Metals-Basel., 2019, vol. 9, p. 10.https://doi.org/10.3390/met9040395.

C. Srishilan and A.K. Shukla: Metall. Mater. Trans. B., 2019, vol. 50B, pp. 312–23.

Y.Z. Pan, A.J. Zhang, L. Lin, J.S. Wang, H.X. Feng and Q.S. Lin: 10th International Symposium on High-Temperature Metallurgical Processing, 2019, pp. 523–30.

National Standard (Standardization Administration of China, 2017), https://kns.cnki.net/kcms/detail/detail.aspx?FileName=SCSF00050625&DbName=SCSF. Accessed 07 September 2017.

S. Pal and A.K. Lahiri: Metall. Mater. Trans. B., 2003, vol. 34B, pp. 103–14.

National Standard (Standardization Administration of China, 2008), https://kns.cnki.net/kcms/detail/detail.aspx?FileName=SCSF00012632&DbName=SCSF. Accessed 13 May 2008.

National Standard (Standardization Administration of China, 2019), https://kns.cnki.net/kcms/detail/detail.aspx?FileName=SCSF00061542&DbName=SCSF. Accessed 31 December 2019.

J. Sternel and A.K. Lahiri: Ironmaking Steelmaking., 1999, vol. 26, pp. 339–48.

M. Sasaki, K. Ono, and A. Suzuki: Tetsu to Hagane., 1976, vol. 62, pp. 559–69.

G. Wang, Q. Xue, and J. Wang: Thermochim. Acta., 2015, vol. 621, pp. 90–8.

P.F. Nogueira and R.J. Fruehan: Metall. Mater. Trans. B., 2005, vol. 36B, pp. 583–90.

I.V. Flores, O. Matos, A.L. Silva, and M.C. Bagatini: Metall. Mater. Trans. B., 2021, vol. 52B, pp. 1716–38.

M.M. Hessien, Y. Kashiwaya, K. Ishii, M.I. Nasr, and A.A. Geassy: Ironmaking Steelmaking., 2008, vol. 35, pp. 183–90.

P.F. Nogueira and R.J. Fruehan: Metall. Mater. Trans. B., 2006, vol. 37B, pp. 551–8.

P. Kaushik and R.J. Fruehan: Ironmaking Steelmaking., 2006, vol. 33, pp. 520–8.

K. Nagata, R. Kojima, T. Murakami, M. Susa, and H. Fukuyama: ISIJ Int., 2001, vol. 41, pp. 1316–23.

S.S. Liu, Y.F. Guo, G.Z. Qiu, and T. Jiang: Rare Met., 2020, vol. 39, pp. 1348–52.

Y.F. Li, Z.J. He, W.L. Zhan, W.G. Kong, P. Han and J.H. Zhang: Metals, 2020, vol. 10. https://doi.org/10.3390/met10091254.

Y.N. Qie, Q. Lyu, C.C. Lan, S.H. Zhang, and R. Liu: J. Iron Steel Res. Int., 2020, vol. 27, pp. 132–40.

T. Kon, S. Natsui, S. Matsuhashi, S. Ueda, R. Inoue, and T. Ariyama: Steel Res. Int., 2013, vol. 84, pp. 1146–56.

A. Inayoshi and S. Hayashi: Tetsu to Hagane., 2010, vol. 96, pp. 586–91.

Y.Z. Pan, H.B. Zuo, B.X. Wang, J.S. Wang, G. Wang, and Y.L. Liu: Ironmaking Steelmaking., 2020, vol. 47, pp. 322–7.

Y.Z. Wang, J.L. Zhang, Z.J. Liu, and C.B. Du: JOM., 2017, vol. 69, pp. 2397–403.

K. Jiao, J. Zhang, Z. Liu, S. Kuang, and Y. Liu: ISIJ Int., 2017, vol. 57, pp. 48–54.

T. Lou, Y. Li, L. Li, and Z. Shui: Acta Metallurgica Sinica, 2000, pp. 141–44.

S.F. Zhang, X. Zhang, W. Liu, X.W. Lv, C.G. Bai, and L.Y. Weng: J. Non-Cryst. Solids., 2014, vol. 402, pp. 214–22.

Z. Yan, R.G. Reddy, X.W. Lv, Z.D. Pang, and C.G. Bai: Metall. Mater. Trans. B., 2019, vol. 50B, pp. 251–61.

Z.D. Pang, X.W. Lv, J. Ling, Y. Jiang, Z. Yan, and J. Dang: Metall. Mater. Trans. B., 2020, vol. 51B, pp. 2348–57.

T. Furukawa and W.B. White: Phys. Chem. Glasses., 1979, vol. 20, pp. 69–80.

D. Virgo, B.O. Mysen, and I. Kushiro: Science., 1980, vol. 208, pp. 1371–3.

Acknowledgments

The work is supported by the National Natural Science Foundation of China (Project No. U2003215). The authors also thank Xinjiang Bayi Iron & Steel Co., Ltd., for providing samples for the experiment.

Conflict of interest

The author declares that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted July 3, 2021; accepted September 15, 2021.

Rights and permissions

About this article

Cite this article

Yin, C., Zhang, S., Yang, X. et al. Smelting Vanadium–Titanium Magnetite by COREX Process: Effect of V–Ti Bearing Pellet Ratio on the Softening and Melting Behavior of Mixed Burden. Metall Mater Trans B 52, 4096–4108 (2021). https://doi.org/10.1007/s11663-021-02331-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-021-02331-2