Abstract

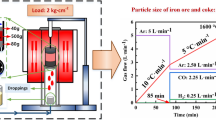

The effect of sinter basicity on softening-melting behaviors of mixed burden made from chromium-bearing vanadium-titanium magnetite (Cr-V-Ti magnetite) was investigated and the function mechanism was simultaneously analyzed. The results show that with increasing sinter basicity from 1.71 to 2.36, the softening interval tends to increase from 149.3 °C to 181.7 °C while the melting interval tends to decrease from 178.0 °C to 136.7 °C. The location of cohesive zone moves downwards firstly and then ascends slightly, but the cohesive zone becomes thinner. The softening-melting characteristic value becomes small, which indicates that the permeability of burden column is improved. The dripping ratio of mixed burden tends to increase firstly and then decrease, which comes to the highest value of 74.50% when the sinter basicity is 2.13. The content and the recovery of V and Cr in dripping iron are all increased. The generation amount of components with high melting point in slag becomes little with the increase of sinter basicity, which could improve the permeability of mixed burden. Taking softening-melting behaviors of mixed burden and recovery of valuable elements into account, the proper sinter basicity is no less than 2.13 for smelting mixed burden made from Cr-V-Ti magnetite in blast furnace.

Similar content being viewed by others

References

DU He-gui. Principle of smelting vanadium-titanium magnetite in the blast furnace [M]. Beijing: Science Press, 1996: 1–2. (in Chinese)

TANG Jue, ZHANG Yong, CHU Man-sheng, XUE Xiang-xin. Preparation of oxidized pellets with high chromium vanadium titanium magnetite [J]. Journal of Northeastern University: Natural Science, 2013, 34(4): 545–550. (in Chinese)

CHEN Xu-ling, HUANG Yun-song, FAN Xiao-hui, GAN Min. Oxidation roasting behavior and concretion properties of vanadiumtitanium magnetite pellet [J]. Journal of Central South University: Science and Technology, 2016, 47(2): 359–366. (in Chinese)

FU Wei-guo, XIE Hong-en. Progress in technologies of vanadium-bearing titanomagnetite smelting in PanGang [J]. Steel Research International, 2011, 82(5): 501–504.

LIAO J L, LI J, WANG X D, ZHANG Z T. Influence of TiO2 and basicity on viscosity of Ti bearing slag [J]. Ironmaking & Steelmaking, 2012, 39(2): 133–139.

HAO Zi-guo, FEI Hong-cai, LIU Lian, TURNER S. Comprehensive utilization of vanadium-titanium magnetite deposits in China has come to a new level [J]. Acta Geologica Sinica: English Edition, 2013, 87(1): 286–287.

ZHANG Yuan-bo, ZHOU You-lian, JIANG Tao, HAN Gui-hong, LI Guang-hui, XU Bin. Applications of MHA binder in oxidized pellets preparation from vanadium, titanium-bearing magnetite concentrates [J]. Journal of Central South University: Science and Technology, 2012, 43(7): 2459–2466. (in Chinese)

LIU Shui-shi, GUO Yu-feng, QIU Guan-zhou, JIANG Tao, CHEN Feng. Solid-state reduction kinetics and mechanism of pre-oxidized vanadium-titanium magnetite concentrate [J]. Transactions of Nonferrous Metals Society of China, 2014, 24(10): 3372–3377.

ZHANG Yong, LIU Jian-xin, CHENG Gong-jin, LIU Zheng-gen, CHU Man-sheng, XUE Xiang-xin. Experiment study on sintering process optimization of high chromium vanadium-titanium magnetite [C]// Characterization of Minerals, Metals, and Materials Processing. San Antonio: TMS Publications, 2013: 363–369.

ZHOU Mi, YANG Song-tao, JIANG Tao, XUE XIANG-xin. Influence of MgO in form of magnetite on properties and mineralogy of high chromium, vanadium, titanium magnetite sinters [J]. Ironmaking & Steelmaking, 2015, 42(3): 217–225.

ZHOU Mi, YANG Song-tao, JIANG Tao, XUE Xiang-xin. Influence of basicity on high-chromium vanadium-titanium magnetite sinter properties, productivity, and mineralogy [J]. JOM, 2015, 67(5): 1203–1213.

ZHOU Mi, JIANG Tao, YANG Song-tao, XUE Xiang-xin. Sintering behaviors and consolidation mechanism of high-chromium vanadium and titanium magnetite fines [J]. International Journal of Minerals, Metallurgy and Materials, 2015, 22(9): 917–925.

TANG Jue, CHU Man-sheng, XUE Xiang-xin. Optimized use of MgO flux in the agglomeration of high-chromium vanadiumtitanium magnetite [J]. International Journal of Minerals, Metallurgy and Materials, 2015, 22(4): 371–380.

CHENG Gong-jin, LIU Jian-xin, LIU Zheng-gen, CHU Man-sheng, XUE Xiang-xin. Non-isothermal reduction mechanism and kinetics of high chromium vanadium-titanium magnetite pellets [J]. Ironmaking & Steelmaking, 2015, 42(1): 17–26.

LIU Jian-xin, CHENG Gong-jin, LIU Zheng-gen, CHU Man-sheng, XUE Xiang-xin. Reduction process of pellet containing high chromic vanadium-titanium magnetite in cohesive zone [J]. Steel Research International, 2015, 86(7): 808–816.

TANG Jue, CHU Man-sheng, LI Feng, TANG Ya-ting, LIU ZHENG-gen, XUE Xiang-xin. Reduction mechanism of high-chromium vanadium-titanium magnetite pellets by H2-CO-CO2 gas mixtures [J]. International Journal of Minerals, Metallurgy and Materials, 2015, 22(6): 562–572.

ZHANG Yong, TANG Jue, CHU Man-sheng, LIU Yang, CHEN Shuang-yin, XUE Xiang-xin. Optimization of BF slag for high Cr2O3 vanadium-titanium magnetite [J]. Journal of Iron and Steel Research International, 2014, 21(2): 144–150.

TOVAROVSKII I G, BOL’SHAKOV V I, TOGOBITSKAYA D N, KHAMKHOT’KO A F. Influence of the softening and melting zone on blast-furnace smelting [J]. Steel in Translation, 2009, 39(1): 34–44.

LIU Xin-liang, WU Sheng-li, HUANG Wei, ZHANG Kai-fa, DU Kai-ping. Influence of high temperature interaction between sinter and lump ores on the formation behavior of primary-slags in blast furnace [J]. ISIJ International, 2014, 54(9): 2089–2096.

LIU Zheng-gen, CHU Man-sheng, WANG Hong-tao, ZHAO Wei, XUE Xiang-xin. Effect of MgO content in sinter on the softeningmelting behavior of mixed burden made from chromium-bearing vanadium-titanium magnetite [J]. International Journal of Minerals, Metallurgy and Materials, 2016, 23(1): 25–32.

SUZUKI H, MIZOGUCHI H, HAYASHI S. Influence of ore reducibility on reaction behavior of ore bed mixed with coal composite iron ore hot briquettes [J]. ISIJ International, 2011, 51(8): 1255–1261.

WU Sheng-li, TUO Bi-yang, ZHANG Li-hua, DU Hai-ping, SUN Ying. New evaluation methods discussion of softening-melting and dropping characteristic of BF iron bearing burden [J]. Steel Research International, 2014, 85(2): 233–242.

CHU Man-sheng, LIU Zheng-gen, WANG Zhao-cai, YAGI J I. Fundamental study on carbon composite iron ore hot briquette used as blast furnace burden [J]. Steel Research International, 2011, 85(5): 521–528.

MA Jia-yuan, SU Xi-wen, SHENG Shi-xiong. Intensified smelting of vanadium and titanium magnetite in blast furnace [J]. Iron and Steel, 2000, 35(1): 4–8. (in Chinese)

KAUSHIK P, FRUEHAN R J. Mixed burden softening and melting phenomena in blast furnace operation Part 1-X-ray observation of ferrous burden [J]. Ironmaking & Steelmaking, 2006, 33(6): 507–519.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(51574067) supported by the National Natural Science Fundation of China; Projects(2012AA062302, 2012AA062304) supported by the National High Technology Research and Development Program of China; Project(N110202001) supported by the Fundamental Research Funds for the Central Universities of China

Rights and permissions

About this article

Cite this article

Wang, Ht., Zhao, W., Chu, Ms. et al. Effect and function mechanism of sinter basicity on softening-melting behaviors of mixed burden made from chromium-bearing vanadium-titanium magnetite. J. Cent. South Univ. 24, 39–47 (2017). https://doi.org/10.1007/s11771-017-3406-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-017-3406-z