Abstract

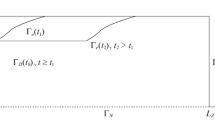

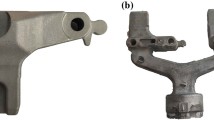

Control of macrosegregation phenomena and deformation-related defects is a main issue in steel continuous casting. Numerical simulation could help industrial engineers to master these defects. However, as a first step, it is essential to achieve a concurrent computation of fluid flow in the bulk liquid and stress-strain evolution in the already solidified regions. With this aim in view, a new specific partitioned solver has been developed to model the liquid flow, essentially induced by the inlet jet distributed by the submerged nozzle, as well as the thermal deformation of the solid shell. The solver procedure allows simulating the transient regime, up to convergence to the steady-state regime. For this purpose, the computational finite element mesh moves and grows continuously. Within this evolving mesh, three different zones are defined: the solid shell as a pure Lagrangian zone, the liquid nozzle region as a pure Eulerian zone, and an intermediate Eulerian–Lagrangian zone. Conservation equations (energy, mass, and momentum) are solved in a general arbitrary Lagrangian–Eulerian framework, with a level-set formulation to track the free surface evolution at the meniscus. The article is composed of two parts. In the first part, the model is detailed with the resolution steps involved in the coupled resolution approach. In the second part, a simple verification test case is firstly proposed, followed by a more relevant and practical application to model an industrial pilot continuous casting process.

Similar content being viewed by others

References

B.G. Thomas, L.J. Mika, F.M. Najjar, Metall. Trans. B 21B, 387–400 (1990)

F.M. Najjar, B.G. Thomas, D.E. Hershey, Metall. Mater. Trans. B 26B, 749–765 (1995)

R. Vertnik, B. Šarler, Eng. Anal. Bound. Elements 45, 45–61 (2014)

C. Pfeiler, M. Wu, A. Ludwig, Mater. Sci. Eng. A 413, 115–120 (2005)

P.E. Ramirez-Lopez, P.D. Lee, K.C. Mills, ISIJ Int. 50, 425–434 (2010)

M.R. Aboutalebi, M. Hasan, R.I.L. Guthrie, Metall. Mater. Trans. B 26B, 731–744 (1995)

A. Noeppel, A. Ciobanas, X.D. Wang, K. Zaidat, N. Mangelinck, O. Budenkova, A. Weiss, G. Zimmermann, Y. Fautrelle, Metall. Mater. Trans. B 41B, 193–208 (2010)

F. Pascon, A.-M. Habraken, Comput. Meth. Appl. Mech. Eng. 196, 2285–2299 (2007)

L.C. Hibbeler, B.G. Thomas, R.C. Schimmel, G. Abbel, Metall. Mater. Trans. B 43B, 1156–1172 (2012)

M. Bellet, A. Heinrich, ISIJ Int. 44, 1686–1695 (2004)

T. Koshikawa, M. Bellet, C.-A. Gandin, H. Yamamura, M. Bobadilla, Acta Mater. 124, 513–527 (2017)

M.L.S. Zappulla, S.-M. Cho, S. Koric, H.-J. Lee, S.-H. Kim, B.G. Thomas, J. Mater. Proces. Tech. 278, 116469 (2020)

S. Koric, L.C. Hibbeler, R. Liu, B.G. Thomas, Numer. Heat Transfer Part B 58, 371–392 (2010)

M. Heil, A.L. Hazel, J. Boyle, Comput. Mech. 43, 91–101 (2008)

S. Zhang, G. Guillemot, C.-A. Gandin, M. Bellet, Comput. Meth. Appl. Mech. Eng. 356, 294–324 (2019)

V.D. Fachinotti, S. Le Corre, N. Triolet, M. Bobadilla, M. Bellet, Int. J. Num. Meth. Eng. 67, 1341–1384 (2006)

A. Ludwig, A. Vakhrushev, M. Wu, T. Holzmann, A. Kharicha, Trans. Indian Inst. Metals 68, 1087–1094 (2015)

C.M.G. Rodrigues, A. Ludwig, M. Wu, A. Kharicha, A. Vakhrushev, Metall. Mater. Trans. B 50B, 1334–1350 (2019)

M. Bellet and B.G. Thomas: Materials Processing Handbook, CRC Press, Taylor and Francis, 2007, Chapter 27, pp. 27-1 – 27-26.

A. Saad, C.-A. Gandin, M. Bellet, Comput. Mater. Sci. 99, 221–231 (2015)

J. Ni, C. Beckermann, Metall. Trans. B 22B, 349–361 (1991)

P.C. Carman: Chem. Eng. Res. Design: Trans. Instit. Chem. Eng. Part A, 1937, vol. 37, pp. 2069-79.

E. Hachem, B. Rivaux, T. Kloczko, H. Digonnet, T. Coupez, J. Comp. Phys. 229, 8643–8665 (2010)

M. Shakoor, B. Scholtes, P.O. Bouchard, M. Bernacki, Appl. Math. Model. 39, 7291–7302 (2015)

T. Coupez, J. Comput. Phys. 230, 2391–2405 (2011)

M. Henri: Modélisation 3D par éléments finis du refroidissement primaire lors de la coulée continue d’aciers (3D Finite Element Modeling of primary cooling during steel continuous casting), Ph.D. Thesis (in French), Ecole Nationale Supérieure des Mines de Paris, 2009.

T.T.M. Nguyen, C.-A. Gandin, H. Combeau, M. Založnik, M. Bellet, Metall. Mater. Trans. A 49A, 1725–1748 (2018)

B.G. Thomas, R. O’Malley, D. Stone: MCWASP VIII Conf. Proc., 1998, TMS, p.1185.

C. Pfeiler, B.G. Thomas, M. Wu, A. Ludwig, A. Kharicha: Steel Research Int., 2006, vol. 77, No.7

J.M. Risso, A.E. Huespe, A. Cardona, Int. J. Numer. Meth. Eng. 65, 1355–1377 (2006)

M.L.S. Zappulla, L.C. Hibbeler, B.G. Thomas, Metall. Mater. Trans. A 48A, 3777–3793 (2017)

Acknowledgments

This work was funded by the European Space Agency – ESTEC (Netherlands) under the projects CCEMLCC (Grant AO-2004-017) and industrial partners ARCELORMITTAL Maizières Research, APERAM ALLOYS IMPHY and INDUSTEEL. The authors would also like to thank Prof. Brian G. Thomas (Colorado School of Mines, and University of Illinois), for fruitful exchanges during the revision of this manuscript.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted August 27, 2020; Accepted December 23, 2020.

Rights and permissions

About this article

Cite this article

Zhang, S., Guillemot, G., Gandin, CA. et al. A Partitioned Solution Algorithm for Concurrent Computation of Stress–Strain and Fluid Flow in Continuous Casting Process. Metall Mater Trans B 52, 978–995 (2021). https://doi.org/10.1007/s11663-021-02070-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-021-02070-4