Abstract

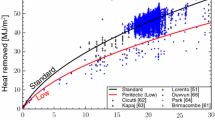

Existing experimental results of weldability tests show the susceptibility of carbon steels to solidification cracking varies significantly with the C content. To analyze the effect of the C content on the susceptibility, equilibrium solidification of binary Fe-C alloys was assumed as an approximation in view of the rapid diffusion of the interstitial solute C in Fe. First, the curve of the equilibrium freezing temperature range vs. the C content was plotted and compared with the experimental results, but the agreement was not good. Then, the susceptibility index, i.e., |dT/d(fS)1/2| near (fS)1/2 = 1 (T: temperature; fS: fraction solid) recently proposed for Al alloys was tried. The curve of the susceptibility index vs. the C content was calculated. The curve agreed well with the experimental results of crack susceptibility tests of carbon steels in welding.

Similar content being viewed by others

References

S. Kou: Welding Metallurgy, 3rd edition. John Wiley and Sons, Inc., Hoboken, NJ, 2020, pp. 323-377.

W. F. Savage and C. D. Lundin: Weld. J., 1965, vol. 44, pp. 433s-42s.

T. Soysal and S. Kou: Weld. J., 2017, vol. 96, pp. 389s-401s.

T. Soysal and S. Kou: Acta Mater., 2018, vol. 143, pp. 181-97.

T. Soysal and S. Kou: J. Mater. Proc. Tech., 2019, vol. 266, pp. 421-8.

K. Liu and S. Kou: Sci. Technol. Weld. Joining, 2020, vol. 25, pp. 251-7.

K. Liu, P. Yu, and S. Kou, Weld. J. 99, 255s–70s (2020)

Xia C, Kou S (2020) Sci Technol Weld Join. https://doi.org/10.1080/13621718.2020.1802897

Xia C, Kou S (2020) Sci Technol Weld Join. https://doi.org/10.1080/13621718.2020.1812211

S. Kou: Acta Mater., 2015, vol. 88, pp. 366-74.

S. Kou: Weld. J., 2015, vol. 94, pp. 374s-88s.

T. Soysal and S. Kou: Sci. Technol. Weld. Joining, 2019, vol. 24, pp. 559-65.

J. Liu and S. Kou: Acta Mater., 2017, vol. 125, pp. 513-23.

J. Liu, H. P. Duarte and S. Kou: Acta Mater., 2017, vol. 122, pp. 47-59.

J. Liu and S. Kou: Acta Mater., 2016, vol. 110, pp. 84-94.

J. Liu and S. Kou: Acta Mater., 2015, vol. 100, pp. 359-68.

AlcoTec Wire Corporation: Aluminum Filler Alloy Chart, AlcoTec Wire Corporation, Traverse, 2020. http://www.alcotec.com/us/en/support/upload/Aluminum_Filler_Alloy_Selection_Chart.pdf. Accessed 6 Aug 2020.

Maxal International, Inc.: Maxal Guide for Aluminum Welding, Maxal International, Inc., Traverse, 2012. http://Maxal.com. Accessed 1 Aug 2012.

N. Coniglio and C.E. Cross: Metall. Mater. Trans. A, 2009, vol. 40, pp. 2718-28.

J. Campbell: Castings, 2nd ed. Butterworth Heinemann, Oxford, UK, 2003, pp. 242-58.

J. Campbell: Private Communications, University of Birmingham, 2014.

S. Kou: Transport Phenomena and Materials Processing, John Wiley and Sons, Inc., Hoboken, NJ, 1996, pp. 64-67.

D.J. Fisher and W. Kurz: Unpublished Research, Department of Materials, EPFL-Swiss Institute of Technology, Lausanne, 1978.

L. Wang, N. Wang and N. Provatas: Acta Mater., 2017, vol. 126, pp. 302-12.

J. Han, J. Wang, M. Zhang and K. Niu: Mater., 2019, vol. 5, pp. 100203.

J. Guo and G. Wen: Metals, 2019, vol. 9, pp. 836.

P. Rong, N. Wang, L. Wang, R. Yang and W. Yao: J. Alloy Compd, 2016, vol. 676, pp. 181-6.

Computherm LLC: Pandat—Phase Diagram Calculation Software Package for Multicomponent Systems, Computherm LLC, Madison, 2020. https://www.computherm.com/. Accessed 1 May 2020.

Computherm LLC: PanIron—Thermodynamic Database for Commercial Iron Alloys, Computherm LLC, Madison, 2020. https://computherm.com/. Accessed 1 May 2020.

V. Shankar and J. H. Devletian: Sci. Technol. Weld. Joining, 2005, vol. 10, pp. 236-43.

T. Senda, F. Matsuda, G. Takano, K. Watanabe, T. Kobayashi and T. Matsuzaka: Trans. Jpn. Weld. Soc. 1971, vol. 2, pp. 141-62.

F. Matsuda, H. Nakagawa, K. Nakata, H. Kohmoto, and Y. Honda: Transactions of JWRI, 1983, vol. 12, pp. 65-72.

S. Ohshita, N. Yurioka, N. Mori and T. Kimura: Weld. J., 1983, vol. 62, pp. 129s-36s.

Amaya T, Yonezawa T, Ogawa K, Peltonen MJ, Hanninen H (2018) Weld J 97:55s-64s

Smith RB (1993) ASM Handbook: Welding, Brazing and Soldering, vol 6. ASM International, Materials Park, OH, pp 641–61

G. Poltarak, S. Ferro and C. Cicutti: Steel Res. Int., 2017, vol. 88, pp. 1600223.

Y. Won, T. Yeo, D. Seol and K. Oh: Metall Mater. Trans. B, 2000, vol. 31B, pp. 779-94.

G. Azizi, B. Thomas and M. Zaeem: Metall Mater. Trans. B, 2020, vol. 51B, pp. 1875-903.

M. Wolf and W. Kurz: Metall Trans. B, 1981, vol. 12B, pp. 85-93.

K. Harste and K. Schwerdtfeger: ISIJ Int., 2003, vol. 43, pp. 1011–20.

T. Soysal and S. Kou: Sci. Technol. Weld. Joining, 2020, vol. 25, pp. 415-21.

N. Bakir, A. Gumenyuk and M. Rethmeier: Sci. Technol. Weld. Joining, 2018, vol. 23, pp. 234-40.

Wolf MM (1997) In: Wolf MM (ed) Continuous Casting: Initial Solidification Strand Surface Quality of Peritectic Steels, vol 9. Iron and Steel Society/AIME, Warrendale, PA, pp 61–65

Acknowledgments

Chunzhi Xia was supported by the Jiangsu Overseas Visiting Scholar Program for University Prominent Young and Middle-aged Teachers and Presidents as a Visiting Professor at the University of Wisconsin-Madison from 2018 to 2019. Sindo Kou was supported by the National Science Foundation initially under Grant No. DMR 1500367 and subsequently under Grant No. DMR1904503.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted August 17, 2020, Accepted October 25, 2020.

Rights and permissions

About this article

Cite this article

Xia, C., Kou, S. Calculating the Susceptibility of Carbon Steels to Solidification Cracking During Welding. Metall Mater Trans B 52, 460–469 (2021). https://doi.org/10.1007/s11663-020-02021-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-020-02021-5