Abstract

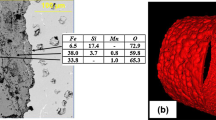

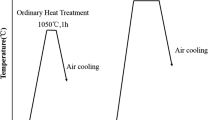

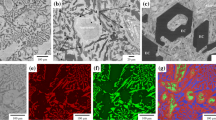

High silicon molybdenum-alloyed cast irons (SiMo) with spherical graphite are widely used for cast thin-wall exhaust manifolds, worked in high-temperature oxidation environment; therefore, prevention of surface degradation during service is important for such common application. The base SiMo and two alloyed by 1 pct Cr and 3 pct Al cast irons were tested at high temperatures in air and a combustion atmosphere to study the microstructural processes of surface degradation. It was shown that surface degradation of SiMo cast irons involves several microstructural processes, including the formation of multilayered oxide scale and development of internal porosity, resulting in decarburization of graphite nodules. Monitoring weight change of the specimens and Leco C analysis were used for decoupling the rates of surface oxidation and metal matrix decarburization. SEM/EDX analysis was used to study the phase composition of scale and high-resolution TEM analysis was performed to determine the detailed information about the atomic structure of protection layers formed on scale/metal matrix interface. The results were used to qualify and link different surface degradation mechanisms. In the base SiMo cast iron, the protection efficiency of formed amorphous silica layers is limited by intensive decarburization at temperatures above 700 °C. It was shown that Cr and Al alloying prevents surface degradation and suppresses decarburization by developing thermally stable oxide films on metal-scale interface, thus allowed to increase a safe working temperature up to 800 °C in air and the combustion atmosphere.

Similar content being viewed by others

References

K. Dawi, J. Favergeon and G. Moulin: Materials Science Forum, Trans Tech Publ., Zurich-Uetikon, 2008, pp 743-751.

Standard SAE J2582: Standard Specification for High-Silicon Molybdenum Ferritic Iron Castings, SAE, 2018.

SAE International: Automotive Ductile Iron Castings for High Temperature Applications, SAE International, 2004.

T. Dorn, J.R. Keough, T. Schroeder, and T. Thoma: Keith Mills Symposium On Ductile Cast Iron, 2003.

S.H. Park, J.M. Kim, H.J. Kim, S.J. Ko, H.S. Park, and J.D. Lim: SAE Technical Paper Series, SAE International, 2005.

6. C. Cvetnic, C. Ravindran and A. McLean, Canadian Metallurgical Quarterly, 2007, vol. 46, pp. 75-88.

M. Ekström: PhD Diss., KTH Royal Institute of Technology, Sweden, 2015.

J.R. Davis: Alloying: Understanding the Basics, ASM International, Materials Park, 2001.

9. V.L. Diaconu, T. Sjögren, P. Skoglund and A. Diószegi: International Journal of Cast Metals Research, 2013, vol. 25, pp. 277-286.

10. M.P. Brady, G. Muralidharan, D.N. Leonard, J.A. Haynes, R.G. Weldon and R.D. England: Oxidation of Metals 2014, vol. 82, pp. 359-381.

11. M. Ekström, P. Szakalos and S. Jonsson: Oxidation of Metals, 2013, vol. 80, pp. 455-466.

12. G.A. Çelik, M.-I.T. Tzini, Ş. Polat, Ş.H. Atapek and G.N. Haidemenopoulos: International Journal of Minerals, Metallurgy and Materials 2020, vol. 27, pp. 1-10.

13. M.M. Ibrahim, A. Nofal and M.M. Mourad: Metallurgical and Materials Transactions B, 2016, vol. 48, pp. 1149-1157.

R.B. Gundlach, D.V. Doane, and A.H. Committee: Properties and Selection: Irons, Steels, and High-Performance Alloys, ASM International, 1990, pp. 85–104.

15. K.H. Choe, S.M. Lee and K.W. Lee: Materials Science Forum, 2010, vol. 654-656, pp. 542-545.

A.R. KianiRashid and D.V. Edmonds: Surface and Interface Analysis, 2004, vol. 36, pp. 1011-1013.

17. H. Asteman, W. Hartnagel and D. Jakobi: Oxidation of Metals, 2013, vol. 80, pp. 3-12.

18. J. Yaker, L. Byrnes, W. Leslie and E. Petitbon: AFS Transactions, 1976, vol. 84, pp. 305-320.

19. M.M. Ibrahim, M.M. Mourad, A.A. Nofal and A.I.Z. Farahat: International Journal of Cast Metals Research, 2017, vol. 30, pp. 61-69.

K. Papis, S. Tunzini, and W. Menk: 10th International Symposium on the Science and Processing of Cast Iron, 2014.

21. S.M. Xiang, B.H. Zhu and S. Jonsson: Materials Science Forum, 2018, vol. 925, pp. 369-376.

22. S. Méndez, M.Á. Arenas, A. Niklas, R. González, A. Conde, J. Sertucha and J.J. de Damborenea: Oxidation of Metals, 2018, vol. 91, pp. 225-242.

23. F. Tholence and M. Norell: Oxidation of Metals, 2007, vol. 69, pp. 13-36.

R.N. Wright: Steel Heat Treating Technologies, J.L. Dossett, and G.E. Totten, eds., ASM International, 2014.

25. D. Li, D. Anghelina, D. Burzic, J. Zamberger, R. Kienreich, H. Schifferl, W. Krieger and E. Kozeschnik: Steel Research International, 2009, vol. 80, pp. 298-303.

26. D. Li, D. Anghelina, D. Burzic, W. Krieger and E. Kozeschnik: Steel Research International, 2009, vol. 80, pp. 304-310.

27. P. Weiβß, J. Brachmann, A. Bührig-Polaczek and S.F. Fischer: Materials Science and Technology, 2014, vol. 31, pp. 1479-1485.

C.W. Bale, P. Chartrand, S. Degterov, G. Eriksson, K. Hack, R. BenMahfoud, J. Melançon, A. Pelton and S. Petersen: Calphad, 2002, vol. 26, pp. 189-228.

29. J.-O. Andersson, T. Helander, L. Höglund, P. Shi and B. Sundman: Calphad, 2002, vol. 26, pp. 273-312.

30. M. Lamkin, F. Riley and R. Fordham: Journal of the European Ceramic Society, 1992, vol. 10, pp. 347-367.

31. P. Harrop: Journal of Materials Science, 1968, vol. 3, pp. 206-222.

32. E. Polman, T. Fransen and P. Gellings: Journal of physics: Condensed matter, 1989, vol. 1, p. 4497.

33. Y. Wang, Y. Sohn, L. An, Y. Fan and L. Zhang: Journal of phase equilibria and diffusion, 2006, vol. 27, pp. 671-675.

34. A. Heuer: Journal of the European Ceramic Society, 2008, vol. 28, pp. 1495-1507.

M. Soiński, and A. Jakubus: Arch. Foundry Eng., 2013.

Acknowledgments

This material is based upon work supported by the US Department of Energy’s Office of Energy Efficiency and Renewable Energy (EERE) under the Award Number DE-EE0008458.

Conflict of interest

The authors declare that they have no conflicts of interest

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted July 8, 2020.

Rights and permissions

About this article

Cite this article

Lekakh, S.N., Bofah, A., Chen, WT. et al. Prevention of High-Temperature Surface Degradation in SiMo Cast Irons by Cr and Al Alloying. Metall Mater Trans B 51, 2542–2554 (2020). https://doi.org/10.1007/s11663-020-01975-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-020-01975-w