Abstract

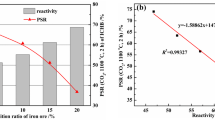

Utilization of iron carbon agglomerates (ICA) is considered to be an innovative technology to realize low carbon blast furnace (BF) ironmaking. The preparation of ICA with utilization of polyvinyl alcohol (PVA) and coal tar pitch (CTP) as binders was proposed in this study. The influence mechanisms of binder addition on the metallurgical properties of ICA were revealed. The results show that adding PVA is beneficial to improving the compressive strength of briquettes due to the chemical adsorption between the binder and the material particles. However, with the increase of PVA addition ratio from 0 to 1.0 pct, the compressive strength of ICA decreases from 2854 N to 2601 N. Meanwhile, the addition of PVA has no effect on the carbon crystallites structure of ICA and the reactivity of ICA present few changes, which are all at about 60 pct with the increase of PVA addition ratio from 0 to 1.0 pct. In addition, as the addition of CTP increases from 0 to 7 pct, the microstructure of ICA becomes dense and less porous, which can improve the compressive strength of ICA from 1639 to 3168 N. Although the reactivity of ICA is slightly reduced from 65.6 to 58.1 pct due to the development of carbon crystallites structure, it is still much higher than that of conventional metallurgical coke (30 to 35 pct). Meanwhile, the post-reaction strength is improved from 11.9 to 19.6 pct. However, as the addition amount of CTP exceeds 7 pct, the beneficial effects of CTP addition are attenuated. CTP is more suitable to be the binder of ICA, and the appropriate ratio of CTP is 7 pct.

Similar content being viewed by others

References

Q. Zhang, Z. Wei, J. Ma, Z. Qiu, T. Du: Appl. Therm. Eng., 2019, 10.1016/j.applthermaleng.2019.04.04

J. Zhao, H. Zuo, Y. Wang, J. Wang, Q. Xue: Ironmak. Steelmak., 2019, https://doi.org/10.1080/03019233.2019.1639029.

H. Wang, M. Chu, W. Zhao, Z. Liu, J. Tang: Metall. Mater. Trans. B, 2019, vol.50, pp. 324-336.

Z. Zhang, J. Meng, L. Guo, Z. Guo: Metall. Mater. Trans. B, 2016, vol.47, pp.467–484.

W. Xu, W. Cao, T. Zhu, Y. Li, B. Wan: Steel Res. Int., 2015, vol 86, pp. 1063–1072.

X. Liu, X. Han, H. Cheng, X. Yin, R. Guo, X. Zhao, Q. Wang: Metall. Res. Technol., 2018, vol. 115, pp. 421-430.

M. Natio, A. Okamato, K. Yamaguchi, T. Yamaguchi, Y. Inoue: Tetsu-to-Hagané, 2001, vol. 87, pp. 357–364.

M. Naito, A. Okamoto, K. Yamaguchi, T. Yamaguchi, Y. Inoue: Nippon Steel Tech. Rep., 2006, vol.94, pp.103–108.

S.Nomura, K. Higuchi, K.Kunitomo, M. Naito: ISIJ Int., 2010, vol. 50, pp.1388–1395.

M. Naito, S. Nomura, K. Kato: Tetsu-to-Hagané, 2010, vol. 96, pp.201–208.

A. Kasai, Y. Matsui: ISIJ Int., 2004, vol. 44, pp.2073–2078.

H. Wang, M. Chu, W. Zhao, R. wang, Z. Liu, J. (2016) Tang: Ironmak. Steelmak, 43, 571-580.

H. Wang, W. Zhao, M. Chu, Z. Liu, J. Tang, Z. Ying: Powder Technol., 2018, vol. 328, pp. 318-328.

H. Wang, M. Chu, J. Bao, D. Han, L. Cao, W. Zhao: J. Iron Steel Res., 2019, vol. 31, pp.103-111.

T. Anyashiki, H. Fujimoto, T. Yamamoto, T. Sato, H. Matsuno, M. Sato, K. Takeda: Tetsu-to-Hagané, 2015, vol. 101, pp. 515–523.

Y. Sekine, H. Fujimoto: ISIJ Int., 2019, vol. 59, pp.1437–1439.

P. Venter, N. Naude: J. S. Afr. I. Min. Metall., 2015, vol.115, pp.329–333.

Y.H. Song, W.J. He, Q.N. Ma, Y.H. Tian, X.Z. Lan: Int. J. Coal Prep. Util., 2020, vol.40, pp.376–388.

S.J. Liu, Z.W. Chang, S. Yang, Q. Zhang, S.G. Ju, W.G. Du, R. Ma, Z. Wang, K.X. Zhang (2020) Asia-Pac J Chem Eng., DOI: 10.1002/apj.2414.

Q. Zhong, Y. Yang, T. Jiang, Q. Li, B. Xu (2016) Fuel Process. Technol., 148, 12–18

China GB/T 4000-2017: Determination of coke reactivity index (CRI) and coke strength after reaction (CSR).

Y. Zhao, Y. Zhang, H. Zhang, Q. Wang, Y. Guo: J. Anal. Appl. Pyrol., 2015, vol. 112, pp. 290-297.

C. Zou, Y. She, R. Shi: Fuel Process. Technol., 2019, vol. 190, pp. 1-12.

K. Alexandrino, Á. Millera, R. Bilbao, M.U. Alzueta: Fuel Process. Technol., 2018, vol. 179, pp.369-377.

L. Jin, X. Bai, Y. Li, C. Dong, H. Hu, X. Li: Fuel Process. Technol., 2016, vol. 147, pp. 41-46.

M. Pawlyta, J. Rouzaud, S. Duber: ScienceDirect., 2015, vol. 84, pp. 479-490.

R. Morga, I. Jelonek, K. Kruszewska: Int. J. Coal Geol., 2014, vol. 134-135, pp.17-23.

R.Morga, I. Jelonek, K. Kruszewska, W. Szulik: Int. J. Coal Geol., 2015, vol.144-145, pp.130-137.

Z. Gai, R. Zhang, J. Bi: Energy & Fuels, 2017, vol. 31, pp. 3759-3767.

A. Sadezky, H. Muckenhuber, H. Grothe, R. Niessner, U. Poschl (2005) Carbon, 43, 1731-1742.

Y. Zhu, X. Zhao, J. Cheng, J. Lu, S. Lai: Spectrosc. Spect. Anal., 2017, vol. 37, pp.1919-1924.

B. Bai, Q. Guo, Y. Li, X. Hu, J. Ma: Energy & Fuels, 2018, vol. 32, pp. 3356-3367.

S. Moraes, J. De Lima, J. Neto, C. Fredericci, E. Saccoccio: Min. Proc. Ext. Met. Rev., 2019, https://doi.org/10.1080/08827508.2019.1604521.

K. Zhang, Y. He, Z. Wang, T. Huang, Q. Li, S. Kumar, K. Cen: Fuel, 2017, vol. 210, pp.738-747.

F. Meng, J. Yu, A. Tahmasebi, Y. Han, H. Zhao, J. Lucas, T. Wall: Energy & Fuels, 2014, vol. 28, pp. 275-284.

S. Patra, A. Pattanaik, V. Rayasam: Can. Metall. Quart., 2019, vol.58, pp. 28-45.

J. Cai, S. Yang, X. Hu, W. Song, Q. Xu, B. Zhou, Y. Song: Fuel, 2019, vol. 253, pp.339-348.

Z. Shi, L. Jin, Y. Zhou, Y. Li, H. Hu: Fuel Process. Technol., 2017, vol.167, pp.648-654.

S. Qiu, S. Zhang, Y. Wu, G. Qiu, C. Sun, Q. Zhang, J. Dang, L. Wen, M. Hu, J. Xu, R. Zhu, C. Bai: Fuel, 2018, vol. 232, pp. 374–383.

K. NaveenKumar, R.Padma, L.Vijayalakshmi, J. MariaNithya (2017) J. Lumin., 182, 208-219.

Sushil Gupta, Veena Sahajwalla, Jonathan Burgo, Pinakin Chaubal, Ted Youmans: Metall. Mater. Trans. B, 2005, vol.36, pp.385-394.

S. Sun, L.Wang, C. Wang, Y. Zhang: Vacuum., 2018, vol.158, pp. 215-217.

Y. Feng, Y. Wang, G. Liu, J. Shen, R. Li, J. Du, Z.Yang, Q. Xu: J. Clean. Prod., 2018, vol.172, pp. 2544-2552.

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China-Liaoning Joint Funds (U1808212), the Fundamental Research Funds of the Central Universities of China (N182504010) and Xingliao Talent Plan (XLYC1902118).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted March 24, 2019.

Rights and permissions

About this article

Cite this article

Bao, J., Chu, M., Wang, H. et al. Evolution Characteristics and Influence Mechanism of Binder Addition on Metallurgical Properties of Iron Carbon Agglomerates. Metall Mater Trans B 51, 2785–2796 (2020). https://doi.org/10.1007/s11663-020-01962-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-020-01962-1