Abstract

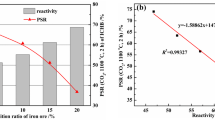

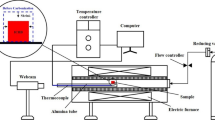

Utilization of iron coke hot briquette (ICHB) has been considered to be one effective countermeasure to achieve low-carbon blast furnace. Before its actual application, a series of extensive fundamental investigations on the ICHB are required. In this study, the influence of iron ore addition on the metallurgical reaction behavior of ICHB made from carbonizing coal–iron ore composite agglomeration were investigated based on Chinese raw material conditions, and the corresponding mechanisms were revealed. The results show that the addition of iron ore concentrate leads to the degradation of the compressive strength and drum strength of ICHB, but they are maintained at a relatively high level. Furthermore, by increasing the addition ratio of iron ore from 0 to 20 pct, the density of ICHB is enhanced from 1413 to 1637 kg/m3, and the porosity is increased from 8.03 to 12.84 pct, and the optical texture index (OTI) is reduced from 58.1 to 25.3. The phase composition of ICHB mainly consists of C, Fe, SiO2, Fe3O4, and FeO after the addition of the iron ore concentrate. Moreover, the reactivity of ICHB is accelerated from 46.74 to 69.54 pct due to the catalytic effects of metallic iron and iron oxide, which worked as oxygen transfer carriers, while the post-reaction strength is reduced from 74.08 to 36.81 pct. In addition, the starting temperature of the ICHB gasification reaction is decreased remarkably from 919 °C to 839 °C. The activation energy (Ea) for the gasification reaction under nonisothermal conditions is reduced from 312.78 to 249.83 kJ/mol, and the preexponential factor (A) shows a decreasing trend as well. Simultaneously, Ea and A display the kinetic compensation effect and present a good linear relationship.

Similar content being viewed by others

References

X. Xing, H. Rogers, G.Q. Zhang, K. Hockings, P. Zulli, A. Deev, J. Mathieson, and O. Ostrovski: Fuel Process. Technol., 2017, vol. 157, pp. 42-51.

W. Xu, W. Cao, T. Zhu, Y. Li, and B. Wan: Steel Res. Int., 2015, vol. 86, pp. 1063-1072.

Z. Zhang, J. Meng, L. Guo, and Z. Guo: Metall. Mater. Trans. B, 2016, vol. 47B, pp. 467-484.

K. Xu: Iron Steel, 2010, vol. 45, pp. 1-12.

H. M. Ahmed, N. Viswanathan and B. Bjorkman: Steel Res. Int., 2014, vol. 85, pp. 293-306.

P. Kowitwarangkul, A. Babich and D. Senk: Steel Res. Int., 2014, vol. 85, pp. 1501-1509.

C. Y. Narita, M. B. Mourao and C. Takano: Ironmak. Steelmak., 2015, vol. 42, pp. 548-552.

S. Nomura, M. Naito, and K. Yamaguchi: ISIJ Int., 2007, vol. 47, pp. 831-839.

S. Nomura, H. Ayukawa, H. Kitaguchi, T. Tahara, S. Matsuzaki, M. Natio, S. Koizumi, Y. Ogata, T. Nakayama, and T. Abe: ISIJ Int., 2005, vol. 45, pp. 316-324.

H. Yokoyama, K. Higuchi, T. Ito, and A. Oshio: ISIJ Int., 2012, vol. 52, pp. 2000-2006.

A. Takashi, F. Kiyoshi, and F. Hidekazu: JFE Tech. Rep., 2009, vol. 13, pp. 1-6.

M. Sato, H. Matsuno, and K. Ishii: Asia Steel Int. Conf., The Iron and Steel Institute of Japan, Yokohama, Janpan, 2015, pp. 12-13.

H. Wang, W. Zhao, M. Chu, C. Feng, Z. Liu, and J. Tang: J. Iron Steel Res. Int., 2017, vol. 24, pp. 751-769.

K. Takeda, T. Anyashiki, T. Sato, N. Oyama, S. Watakabe, and M. Sato: Steel Res. Int., 2011, vol. 82, pp. 512-520.

K. Higuchi, S. Nomura, K. Kunitomo, H. Yokoyama, and M. Naito: ISIJ Int., 2011, vol. 51, pp. 1308-1315.

S. Nomura, K. Higuchi, K. Kunitomo, and M. Naito: ISIJ Int., 2010, vol. 50, pp. 1388-1395.

Y. Yamazaki, K. Hiraki, T. Kanai, X. Zhang, Y. Matsushita, M. Shoji, H. Aoki, and T. Miura: J. Therm. Sci. Technol., 2011, vol. 6, pp. 278-288.

World Steel Association, Blast Furnace Iron Production 1980-2016, 2017.

H. Wang, M. Chu, W. Zhao, R. Wang, Z. Liu, and J. Tang: Ironmak. Steelmak., 2016, vol. 43, pp. 571-580.

H.T. Wang, M.S. Chu, W. Zhao, and Z.G. Liu: J. Northeastern Univ. Nat. Sci., 2016, vol. 37, pp. 810-814.

H.T. Wang, M.S. Chu, W. Zhao, and Z.G. Liu: J. Northeastern Univ. Nat. Sci., 2016, vol. 37, pp. 1108-1112.

ASTM D5314. Standard method for measuring coke reactivity index (CRI) and coke strength after reaction (CSR).

H.T. Wang, W. Zhao, M.S. Chu, Z.G. Liu, J. Tang, and Z.W. Ying: Powder Technol., 2018, vol. 328, pp. 318-328.

Y. Mochizuki, M. Nishio, N. Tsubouchi, and T. Akiyama: Fuel Process. Technol., 2016, vol. 142, pp. 287-295.

N.A. El-Hussiny, and M.E.H. Shalabi: Powder Technol., 2011, vol. 205, pp. 217-223.

P. Wang, S. Yu, H. Long, R. Wei, Q. Meng, and Y. Zhang: Ironmak. Steelmak., 2017, vol. 44, pp. 595-600.

ASTM D5061. Microscopical determination of the textural components of metallurgical coke.

R.J. Gray, and K.F. Devanney: J. Coal Geol., 1986, vol. 6, pp. 277-297.

Z.Z. Yao, and M.D. Zheng: Cokmaking, Metallurgical Industry Publishers, Beijing, 2012, pp. 35-36.

Q. Lv, Y. Wang, H.S. Xie, X.J. Liu, and Y.J. Li, China Metall., 2016, vol. 26, pp. 8-11.

B.D. Flores, A.G. Borrego, M.A. Diez, G.L.R.D. Silva, V.Zymla, A.C.F. Vilela, and E. Osório: Fuel Process. Technol., 2017, vol. 164, pp. 13-23.

B.D. Flores, A. Guerrero, I.V. Flores, A.G. Borrego, M.A. Díez, E. Osório, and A.C.F. Vilela: Fuel Process. Technol., 2017, vol. 155, pp. 238-245.

Y. Tanaka, T. Ueno, K. Okumura, and S. Hayashi: ISIJ Int., 2011, vol. 51, pp. 1240-1246.

S. Nomura, H. Terashima, E. Sato, and M. Naito: ISIJ Int., 2007, vol. 47, pp. 823-830.

J.P. Wang, Q.A. Xie, L.Q. Yan, J.A. Chen, J.S. Hu, and Y.H. Liang: Coal Quality Technol., 2013, vol. 5, pp. 1-6.

J.L. Zhang, J. Guo, G.W. Wang, L.M. Zhang, T. Xu, and C.L. Zheng: Iron Steel, 2016, vol. 51, pp. 22-29.

C. Barriocanal, M.A. Díez, R. Alvarez, M.D. Casal, and C.S. Canga, Anal. Appl. Pyrolysis, 2003, vol. 67, pp. 23-40.

M.J.G. Alonso, D. Alvarez, A.G. Borrego, R. Menéndez, and G. Marbán: Energy Fuel, 2001, vol. 15, pp. 413-428.

K. Watanabe, S. Ueda, R. Inoue, and T. Ariyama: ISIJ Int., 2010, vol. 50, pp. 524-530.

Y. Yamamoto, Y. Kashiwaya, S. Miura, M. Nishimura, K. Katou, S. Nomura, M. Kubota, K. Kunimoto, and M. Naito, Tetsu-to-Hagané, 2010, vol. 96, pp. 297-304.

A.P. Dhupe, A.N. Gokarn, and L.K. Doraiswamy: Fuel, 1991, vol. 70, pp. 839-844.

P. Li, X.G. Bi, S.Z. Shi, H.X. Zhang, and J.D. Zhou: J. Iron Steel Res., 2015, vol. 27, pp. 10-15.

X.L. Wang: Ferrous Metallurgy (Ironmaking), Metallurgical Industry Press, Beijing, 2008, pp. 200-201.

H. Shi, J. Huang, and L.R. Song: J. Iron Steel Res., 2016, vol. 28, pp. 35-39.

A.O. Oyedun, C.Z. Tee, S. Hanson, and C.W. Hui: Fuel Process. Technol., 2014, vol. 128, pp. 471-481.

C. Popescu, and E. Segal: Int. J. Chem. Kinet., 1998, vol. 30, pp. 313-327.

X.J. Zhang, D.J. Wiebren, and P. Fernando: Biomass Bioenergy, 2009, vol. 33, pp. 1435-1441.

K.J. Li, J.L. Zhang, Z.J. Liu, X.J. Ning, and T.J. Yang: Ind. Eng. Chem. Res., 2014, vol. 53, pp. 5737-5748.

A.W. Coats, and J.P. Redfern: Nature, 1964, vol. 201, pp. 68-69.

W.J. Duan, Q.B. Yu, H.Q. Xie, Q. Qin: Energy, 2017, vol. 135, pp. 317-326

J.G. Shao, R. Yan, H.P. Chen, H.P. Yang, and D.H. Lee: Fuel Process. Technol., 2010, vol. 91, pp. 1113-1118.

M.V. Kok: Fuel Process. Technol., 2011, vol. 92, pp. 1026-1031.

A.M. Cortés, and A.V. Bridgwater: Fuel Process. Technol., 2015, vol. 138, pp. 184-193.

S. Vyazovkin, A.K. Burnham, J.M. Criado, L.A. Pérez-Maqueda, C. Popescu, and N. Sbirrazzuoli: Thermochim. Acta, 2011, vol. 520, pp. 1-19.

Y.T. Kim, D.K. Seo, and J. Hwang: Energy Fuels, 2011, vol. 25, pp. 5044-5054.

B.B. Uzun, and E. Yaman: J. Energy Inst., 2016, vol. 9, pp. 1-13.

G. Skodras, G. Nenes, and N. Zafeiriou: Appl. Therm. Eng., 2015, vol. 74, pp. 111-118.

M.C. Wilson, and A.K. Galwey: Nature, 1973, vol. 243, pp. 402-404.

Acknowledgments

This study was financially supported by the National Natural Science Foundation of China (U1808212), the China Postdoctoral Science Foundation (2016M601321), and the Fundamental Research Funds of the Central Universities of China (N162503003).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Manuscript submitted December 28, 2017.

Rights and permissions

About this article

Cite this article

Wang, H., Chu, M., Zhao, W. et al. Influence of Iron Ore Addition on Metallurgical Reaction Behavior of Iron Coke Hot Briquette. Metall Mater Trans B 50, 324–336 (2019). https://doi.org/10.1007/s11663-018-1481-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-018-1481-7