Abstract

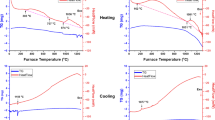

Crude ferronickel alloy can be produced by the carbothermal reduction of laterite ore-coal composite. The size of ferronickel particles in semi-molten state is crucial for the subsequent magnetic separation between the ferronickel and slag. Aimed to better understand the effects of reducing parameters on the size of ferronickel particles in the reduced laterite nickel ores, a series of carbothermal reduction experiments of laterite ore-coal composite in tall pellets bed was carried out. The experimental results indicated that, higher reducing temperature, longer reducing time and more CaO additive were beneficial for the aggregation and growth of ferronickel particles. Temperature (1400 °C) is the most important parameter. Less CaO additive needs longer reducing time, more CaO additive needs shorter reducing time. Excessive CaO amount (CaO = 10 pct) may prevent ferronickel particles from aggregation and growth due to its rapid melting. The importance ranking of these parameters should be temperature > time > CaO additive. The optimum reduction parameters were “1400 °C, 45 minutes, CaO = 0 pct” and “1400 °C, 30 minutes, CaO = 5 pct”. Under these conditions, all the ferronickel particles in 4 layers were clear and bigger. The percentages of + 50 μm of particles were about 65 and 59 pct respectively, and the recovery rates of Ni were about 88 and 85 pct. The findings from this work may provide guidelines for the improvement of ferronickel alloy production by laterite nickel ores.

Similar content being viewed by others

References

1. K. Tozawa: Tetsu-to-Hagané, 1993, vol. 79, pp. 537-547.

2. M.J. Rao, G.H. Li, T. Jiang, J. Luo, Y.B. Zhang and X.H. Fan: JOM, 2013, vol. 65, pp. 1573-1583.

3. S. Mohanty, S.K. Roy and P.K. Sen: Metall. Mater. Trans. B, 2008, vol. 39B, pp. 639-642.

4. Z.W. Peng and J.Y. Hwang: Int. Mater. Rev., 2015, vol. 60, pp. 30-63.

5. M.G. King: JOM, 2005, vol. 57, pp. 35-39.

6. M.Y. Solar and S. Mostaghel: Trans. Inst. Min. Metall. C, 2015, vol. 124, pp. 35-46.

7. T. Watanabe, S. Ono, H. Arai and T. Matsumori: Int. J. Miner. Process, 1987, vol. 19, pp. 173-187.

8. A.E.M. Warner, C.M. Diaz, A.D. Dalvi, P.J. Mackey and A.V. Tarasov: JOM, 2006, vol. 58, pp. 11-20.

9. K. Ishii: Int. J. Miner. Process., 1987, vol. 19, pp. 15-24.

10. X.M. Li, Y. Li, X.Y. Zhang, Z.Y. Wen and X.D. Xing: Metall. Mater. Trans. B, 2020, vol. 51B, pp. 925-936.

11. V.D.A. Oliveira, C.G.D. Santos and E.D.A. Brocchi: Metall. Mater. Trans. B, 2019, vol. 50B, pp. 1309-1321.

12. B. Li, Z.G. Ding, Y.G. Wei, H. Wang, Y.D. Yang and M. Barati: Metall. Mater. Trans. B, 2018, vol. 49B, pp. 3067-3073.

13. Y. Kobayashi, H. Todoroki and H. Tsuju: ISIJ Int., 2011, vol. 51, pp. 35-40.

14. G.J. Chen, W.S. Hwang, S.H. Liu and J.S. Shiau: Mater. Trans., 2015, vol. 56, pp. 550-555.

15. G.H. Li, J. Luo, Z.W. Peng, Y.B. Zhang, M.J. Rao and T. Jiang: ISIJ Int., 2015, vol. 55, pp. 1828-1833.

16. X.M. Lv, W. Lv, M. Liu, Z.X. You, X.W. Lv and C.G. Bai: ISIJ Int., 2018, vol. 58, pp. 799-807.

17. B. Li, Z.G. Ding, Y.G. Wei, S.W. Zhou and H. Wang: Mater. Trans., 2018, vol. 59, pp. 1180-1185.

18. S.W. Zhou, Y.G. Wei, B. Li, H. Wang, B.Z. Ma and C.Y. Wang: Metall. Mater. Trans. B, 2016, vol. 47B, pp. 145-153.

19. H. Tsuji and N. Tachino: ISIJ Int., 2012, vol. 52, pp. 1951-1957.

20. H. Tsuji: ISIJ Int., 2012, vol. 52, pp. 1000-1009.

21. X. Jiang, S.H. Liu, T.Y. Huang, G.Q. Zhang, H. Guo, G.H. Shiau and F.M. Shen: ISIJ Int., 2016, vol. 56, pp. 88-93.

M.X. Chen: Northeastern University, China, 2013, Master thesis, pp. 33–41 (in Chinese).

Acknowledgment

The financial supports of National Science Foundation of China (NSFC 51874080, NSFC 62001312 and NSFC 51974073) are much appreciated.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted May 29, 2020.

Rights and permissions

About this article

Cite this article

Jiang, X., He, L., Wang, L. et al. Effects of Reducing Parameters on the Size of Ferronickel Particles in the Reduced Laterite Nickel Ores. Metall Mater Trans B 51, 2653–2662 (2020). https://doi.org/10.1007/s11663-020-01961-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-020-01961-2