Abstract

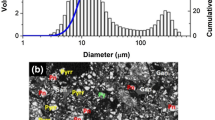

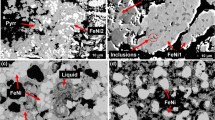

Solid-state thermal treatment of Ni sulfide concentrates in an inert or reducing atmosphere, and the presence of metallic Fe is proposed as a feasible route to produce ferronickel (FeNi) alloy while retaining S in iron sulfides. The present work investigated the effects of temperature and amount of Fe addition via a thermodynamic analysis, giving a suitable temperature of 973 K to 1173 K and metallic Fe to Ni concentrates mass ratio of 0.5 to 2. The minimum time required for Ni extraction at 1073 K was investigated via thermal treatment experiments of various durations, and it was determined to be 30 minutes. Under the tested experimental conditions, average Ni concentration in the resulting sulfides and the generated FeNi was found to be 0.5 ± 0.2 mass pct and 16 to 18 mass pct, respectively, and in good agreement with the thermodynamic predictions. The maximum Ni recovery to FeNi was approximately 97 pct and the characteristic particle sizes d10 and d80 of FeNi were 14 and 45 µm, respectively. During 360 minutes of the thermal treatment, only 0.7 mass pct of S in the concentrates was released to the off gas as SO2.

Similar content being viewed by others

Reference

A. Bautista, G. Blanco, and F. Velasco: Cem. Concr. Res., 2006, vol. 36, pp. 1922–30.

D. Ryoo, N. Kang, and C. Kang: Mater. Sci. Eng. A, 2011, vol. 528, pp. 2277–81.

L.N. Zhang and O.A. Ojo: Metall. Mater. Trans. A, 2018, vol. 49, pp. 295–304.

C. Chakkaravarthy, P. Periasamy, S. Jegannathan, and K.I. Vasu: J. Power Sources, 1991, vol. 35, pp. 21–35.

F.K. Crundwell, M.S. Moats, V. Ramachandran, T.G. Robinson, and W.G. Davenport: Extractive Metallurgy of Nickel, Cobalt and Platinum Group Metals, Elsevier, 2011, pp. 21–37.

D.Q. Zhu, Y. Cui, K. Vining, S. Hapugoda, J. Douglas, J. Pan, and G.L. Zheng: Int. J. Miner. Process., 2012, vol. 106–109, pp. 1–7.

F.K. Crundwell, M.S. Moats, V. Ramachandran, T.G. Robinson, and W.G. Davenport: Extractive Metallurgy of Nickel, Cobalt and Platinum Group Metals, Elsevier, 2011, pp. 247–57.

G. Li, H. Cheng, S. Chen, X. Lu, Q. Xu, and C. Lu: Metall. Mater. Trans. B, 2018, vol. 49, pp. 1136–48.

W. Mu, F. Cui, H. Xin, Y. Zhai, and Q. Xu: Hydrometallurgy, 2020, vol. 191, p. 105187.

W. Mu, F. Cui, Z. Huang, Y. Zhai, Q. Xu, and S. Luo: J. Clean. Prod., 2018, vol. 177, pp. 371–7.

D. Yu, T.A. Utigard, and M. Barati: Metall. Mater. Trans. B, 2014, vol. 45B, pp. 653–61.

D. Yu, T.A. Utigard, and M. Barati: Metall. Mater. Trans. B, 2014, vol. 45B, pp. 662–74.

R. Sridhar, A. Dalvi, H.F. Bakker, and A. Illis: Can. Metall. Q., 1976, vol. 15, pp. 255–62.

F. Liu, D. Yu, S. Marcuson, F. Wang, B. Li, and M. Barati: Miner. Eng., 2019, vol. 134, pp. 206–14.

D. Yu, F. Liu, J. Zhang, and M. Barati: Metall. Mater. Trans. B, 2019, vol. 50, pp. 2186–96.

F. Wang, F. Liu, R. Elliott, S. Rezaei, L.T. Khajavi, and M. Barati: J. Alloys Compd., 2020, vol. 822, p. 153582.

H.M. Cobb: Steel Products Manual: Stainless Steels, Warrendale, 1999.

C.W. Bale, E. Bélisle, P. Chartrand, S.A. Decterov, G. Eriksson, A.E. Gheribi, K. Hack, I. Jung, Y. Kang, J. Melançon, A.D. Pelton, S. Petersen, C. Robelin, J. Sangster, P. Spencer, and M. Van Ende: Calphad, 2016, vol. 54, pp. 35–53.

F.K. Crundwell, M.S. Moats, V. Ramachandran, T.G. Robinson, and W.G. Davenport: Extractive Metallurgy of Nickel, Cobalt and Platinum Group Metals, Elsevier, 2011, pp. 49–53.

O. Polyakov: Handbook of Ferroalloys Theory and Technology, 12th ed., Elsevier, New York, 2013, pp. 367–75.

B. V. Miller and R.W. Limes: Crit. Rev. Anal. Chem., 1988, vol. 20, pp. 75–116.

F.M. Etzler and R. Deanne: Part. Part. Syst. Charact., 1997, vol. 14, pp. 278–82.

B. Wills and J. Finch: Wills’ Mineral Processing Technology, 8th ed., Elsevier, New York, 2015, pp. 1–27.

Acknowledgments

The authors wish to acknowledge the financial support from the Natural Science and Engineering Research Council of Canada (NSERC, STPGP 479533-15), Process Research Ortech Inc., and technical support from XPS Consulting & Testwork Services, Glencore and Vale Canada. Fanmao Wang was partially supported by the China Scholarship Council (CSC, No. 201708530245). Sincere thanks to Dr. Abdolkarim Danaei for his help with the experiments. Mr. Richard Elliott and Mr. Feng Liu also provide insightful discussions for this research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted on May 28, 2020.

Rights and permissions

About this article

Cite this article

Wang, F., Marcuson, S., Khajavi, L.T. et al. Optimum Treatment Time for Solid-State Extraction of Nickel from Nickel Sulfide Concentrates at 1073 K. Metall Mater Trans B 51, 2642–2652 (2020). https://doi.org/10.1007/s11663-020-01960-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-020-01960-3