Abstract

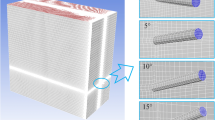

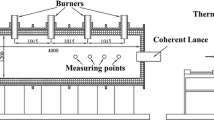

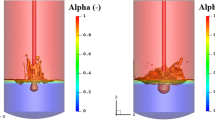

The technology of submerged CO2-O2 injection was developed to enhance the circulation in liquid baths and accelerate the smelting reaction rate in electric arc furnace (EAF) steelmaking. In this study, the effect of submerged gas injection on the EAF liquid bath flowing characteristics was studied and analyzed using numerical simulations, water model experiments, and industrial application research. The results demonstrate that the flow rate of the gas supply, horizontal arrangement mode, and vertical dip angle of the submerged nozzle have a significant impact on stirring in the liquid bath. The horizontal arrangement mode of the two submerged nozzles influences bath circulation in the EAF by determining the collision among the fluid flow streams due to the promotion of submerged nozzles. Compared with Mode A and Mode C, Mode B can improve the molten bath stirring with better temperature and composition homogeneity. The erosion rate of the fire brick around the submerged nozzle in Mode B is 2.42 mm/heat, which is less than that in both Mode A and Mode C.

Similar content being viewed by others

References

B. Lee and I. Sohn: JOM, 2014, vol. 66, pp. 1581-94.

M. Lv, R. Zhu, and L. Yang: Steel Research Int., 2019, vol. 90, 1800454.

L.F. Li, M.F. Jiang, and Z.Y. Duan: Steelmaking, 1996, vol. 12 (2), pp. 49-52.

M. Lv and R. Zhu: Metall. Res. Technol. 2019, vol. 116, 502.

M. Alam, J. Naser, G. Brooks and A Fontana: Metall. Mater. Trans. B, 2010, vol. 41, pp. 1354-67.

M. Alam, J. Naser, G. Brooks and A. Fontana: ISIJ Int., 2012, vol. 52, pp. 1026-35.

G. Wei, R. Zhu, X. Wu, K. Dong, L. Yang, and R. Liu: JOM, 2018, vol. 70, pp. 969-76.

G. Wei, R. Zhu, T. Tang, K. Dong, and X. Wu: Metall. Mater. Trans. B, 2019, vol. 50, pp. 1077-90.

F.H. Liu, R. Zhu, K. Dong, X. Bao, S. L. Fan. ISIJ Int., 2015, vol. 55, pp. 2365-73.

M. Ramirez, J. Alexis, G. Trapaga, P. Jönsson, and J. Mckelliget: ISIJ Int., 2001, vol. 41, pp. 1146-55.

M. Alam, G. Irons, G. Brooks, A. Fontana, J. Naser: ISIJ Int., 2011, vol. 51, pp. 1439-47.

J. Ma, P. Zhou and W. Cheng: Experimental Thermal & Fluid Science, 2016, vol. 75, pp. 220-27.

S. Zhan, C. Lai and T. Hsiao: J. CENT. SOUTH UNIV. TECHNOL., 2003, Vol. 32, pp. 148-51.

G. Caffery, D. Warnica, N. Molloy and M. Lee: Int. Conf. on CFD in Minaral & Metal Processing and Power Generation, CSIRO, 1977, pp. 87–100.

B. Li: ISIJ Int., 2000, vol. 40, pp. 863-69.

V. Singh, J. Kumar, C. Bhanu, S. K. Ajmani, and S. K. Dash: ISIJ Int., 2007, vol. 47, pp. 1605-12.

X. Zhou, M. Ersson, L. Zhong, J. Yu, and P. Jonsson: Steel Res. Int., 2014, vol. 85, pp. 273-81.

M. J. (1993) Norusis: SPSS for Windows: Base System User’s Guide Release 5.0. 1993. Chicago, IL:SPSS

C.W. Hirt and B.D. Nichols: J. Comput. Phys., 1981, vol. 39, pp. 201-25.

G. Wei, R. Zhu, K. Dong, G. Ma, and T. Cheng: Metall. Mater. Trans. B, 2016, vol. 47B, pp. 3066-79.

B.E. Launder and D.B. Spalding: Lectures in Mathematical Model of Turbulence, Academic Press, London, 1972, pp. 124-29.

Q. Li, M. Li, S. Kuang, and Z. Zou: Can. Metall. Q., 2014, vol. 53, pp. 340-51.

A. Pnrunak: Technometrics, 1988, vol. 30, pp. 237-39.

Acknowledgments

The authors would like to express their thanks for the support by the Fundamental Research Funds for the Central Universities (FRF-TP-19-031A1), the China Postdoctoral Science Foundation (2019M660459), and the National Nature Science Foundation of China (No. 51734003, No. 51804345, & No. 51604022).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted August 09, 2019.

Rights and permissions

About this article

Cite this article

Wei, G., Zhu, R., Han, B. et al. Simulation and Application of Submerged CO2-O2 Injection in Electric Arc Furnace Steelmaking: Modeling and Arrangement of Submerged nozzles. Metall Mater Trans B 51, 1101–1112 (2020). https://doi.org/10.1007/s11663-020-01816-w

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-020-01816-w