Abstract

In this study, the deoxidation behavior of Zr powder with the use of a Mg reductant is discussed. The original Zr powder was produced by the hydride-dehydride (HDH) method. The raw Zr powder has a thick surface oxide layer of 43 nm as well as high oxygen concentration in the inner part of the powder. The raw Zr powder carries out the reduction reaction with the Mg agent, which maintains self-propagating high-temperature synthesis (SHS) by releasing significant exothermic heat, thereby decreasing the oxygen content. The surface oxide layer of the deoxidized Zr powder is thinner than that of the raw Zr powder, as observed by transmission electron microscopy (TEM) and Auger electron spectroscopy (AES). Furthermore, the oxygen atoms in the inner part of the Zr powder are easily released by a bcc structure providing more active migration of interstitial atoms induced by the open structure at high temperature, and the emitted oxygen atoms readily react with the Mg agent. The lattice parameters of the deoxidized Zr powders, therefore, are decreased with the reduction of oxygen content in comparison with the raw Zr powder because of shrinkage by the decrease of the excess oxygen interstitial atoms. These results are consistent with the observation that the oxygen content in the raw and deoxidized Zr powder was reduced from 0.595 to 0.338 wt pct due to the decreased surface oxide layer and oxygen content in the inner part of the Zr powder, respectively. It is, thus, confirmed that the Mg agent is capable of playing an important role in the deoxidation behavior in Zr powder to obtain high-purity Zr powder.

Similar content being viewed by others

Notes

LECO is a trademark of LECO Corporation, St. Joseph, MI.

References

M. Hrovat, D. Belavic, A. Bencan, and J. Holc: J. Eur. Ceram. Soc., 2003, vol. 23, pp. 1441–47.

Nielsen R, Chang TW (1996) Ullman’s Encyclopaedia of Industrial Chemistry, 5th ed. Wiley, New York, pp. 543–67.

T.A. Giogri, B. Ferraio, and B. Storey: J. Vac. Sci. Technol. A, 1985, vol. 3, pp. 417–25.

J.S. Park, W.B. Kim, and M.S. Won: Mater. Trans., 2007, vol. 48 (5), pp. 1012–16.

C. Benvenuti and P. Chggiato: Vacuum, 1993, vol. 44, pp. 511–13.

X.Y. Cui, Q. Li, K.C. Chou, S.L. Chen, G.W. Lin, and K.D. Xu: Intermetallics, 2008, vol. 16, pp. 662–67.

E.Y. Anikina and V.N. Vervetsky: J. Alloys Compd., 2007, vol. 446–447, pp. 443–46.

Kim JH, Lee H, Hwanga KT, Han JS (2009) Int. J. Hydr. Energy 34:9424–30

Y.K. Agrawal and S. Sudhaka: Separ. Purif. Technol., 2002, vol. 27, pp. 111–19.

N.N. Greenwood and A. Earnshaw: Chemistry of the Elements, 2nd ed. Oxford: Butterworth-Heinemann. 1997, pp. 954–75.

C. Zheng, T. Ouchi, A. Iizuka, Y. Taninouchi, and T.H. Okabe: Metall. Mater. Trans. B, 2019, vol. 50B, pp. 622–31.

L. Kong, T. Ouchi, and T.H. Okabe: Mater. Trans., 2019, vol. 60 (9), pp. 2059–68.

O.D. Neikov, S.S. Naboychenko, and I.B. Murashova: Handbook of Non-Ferrous Metal Powders, 2nd ed. Elsevier, New York, 2019, pp. 757–829.

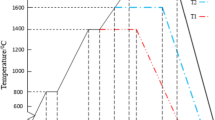

Murray JL, Wriedt HA (1987) Bull. Alloy Phase Diag. 8(2):148–65

G. Ottaviani, F. Nava, G. Queirolo, G. Iannuzzi, G. De Santi, and K.N. Tu: Thin Solid Films, 1987, vol. 146, pp. 201–07.

T.H. Okabe: Ph.D. Thesis, Kyoto University, Kyoto, Japan, 1993.

M.T. Epworth and R. Schuhmann, Jr.: Trans. TMS-AIME, 1962, vol. 224, pp. 928–35.

R.O. Suzuki, K. Teranuma, and K. Ono: Metall. Mater. Trans. B, 2003, vol. 34B, pp. 287–95.

T.H. Okabe, K. Hirota, E. Kasai, F. Saito, Y. Waseda, and K.T. Jacob: J. Alloys Compd., 1998, vol. 279, pp. 184–91.

T.H. Okabe, T. Oishi, and K. Ono: J. Alloys Compd., 1992, vol. 184, pp. 43–56.

K. Hirota, T.H. Okabe, F. Saito, Y. Waseda, and K.T. Jacob: J. Alloys Compd., 1999, 282, pp. 101–08.

C.J. Baroch and G.H. Beyer: U.S. Atomic Energy Commission Report No. ISC-720, U.S. Atomic Energy Commission, Washington, DC, 1956, pp. 1–18.

M. Eshed, S. Pol, A. Gedanken, and M. Balasubramanian: Beilstein J. Nanotechnol., 2011, vol. 2, pp. 198–203.

D.P. Barbis, R.M. Gasior, G.P. Walker, J.A. Capone, and T.S. Schaeffer: Titanium Powder Metallurgy: Science, Technology and Applications, Butterworth-Heinemann, Oxford. 2015, pp. 101–16.

T.S. Krishnan and S. Chaudhary: Trans. Powd. Metall. Assoc. India, 1976, vol. 3, pp. 56–63.

M. Mitkov and D. Božić: Mater. Charact., 1996, vol. 37, pp. 53–60.

B.A. Kolachev, P.D. Drozdov, and N.Y. Guselnikov: Izv. Vuzov. Tsvet. Metallurgiya, 1975, vol. 5, pp. 71–74.

X. Su, F. Fu, Y. Yan, G. Zheng, T. Liang, Q. Zhang, X. Cheng, D. Yang, H. Chi, X. Tang, Q. Zhang, and C. Uher: Nat. Commun., 2014, vol. 5 (4908), pp. 1–7.

A.G. Merzhanov and A.E. Sytschev: SHS for Materials, Combustion Science & Technology Book Series, vol. 5. Taylor & Francis, New York, 2002, pp. 301–22.

J.M. Oh, B.K. Lee, C.Y. Suh, S.W. Cho, and J.W. Lim: Powder Metall., 2012, vol. 55, pp. 402–04.

J.W. Lim, J.M. Oh, B.K. Lee, C.Y. Suh, and S.W. Cho: U.S. Patent No. 8,449,646, 2013.

G. Lutjering and J.C. Williams: Titanium, Springer, New York, 2007.

M.H. Song, S.M. Han, D.J. Min, G.S. Choi, and J.H. Park: Scripta Mater., 2008, vol. 59, pp. 623–26.

K.H. Heo, N.R. Munirathnam, J.W. Lim, M.T. Le, and G.S. Choi: Mater. Chem. Phys., 2008, vol. 112, pp. 923–27.

J.M. Oh, B.G. Lee, S.W. Cho, S.W. Lee, G.S. Choi, and J.W. Lim: Met. Mater. Int., 2011, vol. 17, pp. 733–36.

R.A. Versaci and M. Ipohorski: Cómision Nacional de Energía Atómica, Buenos Aires, Argentina, 1991.

B. Puchala and A. Van der Ven: Phys. Rev. B, 2013, vol. 88, pp. 1–15.

J.M. Oh, H. Kwon, W.B. Kim, and J.W. Lim: Thin Solid Films, 2014, vol. 551, pp. 98–101.

N. Stojilovic, E.T. Bender, and R.D. Ramsier: Progr. Surf. Sci., 2005, vol. 78, pp. 101–84.

Y. Chen, Q. Hu, S. Pan, H. Zhang, H. Liu, B. Zhu, X. Liu, and W. Liu: Metals, 2019, vol. 9 (524), pp. 1–27.

R. Shao, S. Chen, Z. Dou, J. Zhang, X. Ma, R. Zhu, J. Xu, P. Gao, and D. Yu: Nano Lett., 2018, vol. 18 (9), 6094–99.

Y. Wang, C. Cai, L. Li, Y. Li, Y. Zhou, and G. Zhou: AIP Adv., 2016, vol. 6 (95113), pp. 1–9.

H. Shen, L.A. Bendersky, K. Young, and J. Nei: Materials, 2015, vol. 8 (7), pp. 4618–30.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted August 8, 2019.

Rights and permissions

About this article

Cite this article

Kim, H.L., Yun, C.G., Ju, J.H. et al. Deoxidation Behavior of Zr Powder Manufactured by Using Self-Propagating High-Temperature Synthesis with Mg Reducing Agent. Metall Mater Trans B 51, 1070–1078 (2020). https://doi.org/10.1007/s11663-020-01815-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-020-01815-x