Abstract

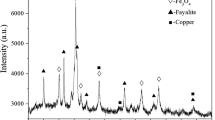

Coal-based direct reduction of nickel slag and magnetic separation of iron are effective methods of secondary resource utilization. The growth characteristics of metallic iron particles in this process are of great significance for subsequent grinding and magnetic separation process. The nickel slag is mixed with coal powder and other additives in a certain proportion, and then subjected to a direct reduction experiment in a high-temperature furnace. Chemical analysis is made to obtain the components of the direct reduction product. The microstructure of the metallic iron particles in the reduction product was studied and the curves of average diameter change and the cumulative diameter percentage of the iron particles are obtained in the reduction process. The results show that the coal-based direct reduction technology can effectively reduce the iron oxides in the nickel slag, and the degree of metallization of the product can reach 91.89 pct. When the reduction time is increased from 10 to 60 minutes, the maximum size of metallic iron particles increases from 13 to 135 μm. The control mechanism of iron particle growth is complicated, and the process is divided into two stages. The growth kinetic parameters (kinetics index, activation energy, and pre-exponential factor) in the two stages are 0.4697, 249.04 kJ mol−1, 3.81 × 108 and 1.0774, 92.93 kJ mol−1, 217.30, respectively. The growth model of metallic iron particles in the direct reduction of nickel slag is also constructed in the paper.

Similar content being viewed by others

References

Y.S. Sun, Q. Zhang, Y.X. Han, P. Gao and G.F. Li: JOM, 2018, vol. 70, pp. 144-49.

C. Cheng, Q.G. Xue, G. Wang, Y.Y. Zhang and J.S. Wang: Metall. Mater. Trans. B, 2016, vol. 47, pp. 154-63.

N. Peng, B. Peng, L.Y. Chai, M. Li, J.M. Wang, H. Yan and Y. Yuan: Miner. Eng., 2012, vol. 35, pp. 57-60.

Y.S. Sun, Y.X. Han, P. Gao, Z.H. Wang, D.Z. Ren: Int. J. Miner. Metall. Mater., 2013, vol. 20, pp. 411-19.

C.F. Zhang, H.X. Liu and D.L. Zhong: Chin. J. of Nonferrous Met., 1999, vol. 9,pp. 805-10.

S. Wang, W. Ni, K.Q. Li, C.L. Wang and J.Y. Wang: Trans. Mater. Heat Treat., 2014, vol. 35, pp. 23-28.

S. Wang, W. Ni, K.Q. Li, C.L. Wang and J.Y. Wang: Trans. Mater. Heat Treat., 2015, vol. 36, pp. 7-12.

P. Gao, Y.S. Sun, D.Z. Ren and Y.X. Han: Miner. Metall. Process., 2013, vol. 30, pp. 74-78.

D.Q. Zhu, Y.Z. Xiao, T.J. Chun and J. Pan: Chin J Nonferrous Met., 2013, vol. 23, pp. 3242-47.

J. Pan, G.L. Zhang, D.Q. Zhu and X.L. Zhou: Trans. Nonferrous Met. Soc. China, 2013, vol. 23, pp. 3421-27.

Y.G. Guo, R. Zhu, Z.Y. Pei, M.S. Ma, Y. Wang and J. Liu: China Nonferrous Metall., 2017, vol. 10, pp. 75-80.

J. Luo, G.H. Li, Z.W. Peng, M.J. Rao, Y.B. Zhang and T. Jiang: JOM, 2016, vol. 68, 3015-21.

P. Gao, Y.X. Han, Y.J. Li and Y.S. Sun: J. Northeast. Univ. Nat. Sci., 2012, vol. 33, pp. 133-36.

M.S. Chu, Z.G. Liu, Z.C. Wang, K.J. Wu and J.P. Lv: China Metall., 2011, vol. 21, pp. 17.

D.Q. Zhu, T.J. Chun and J. Pan: J. Univ. Sci. Technol. Beijing, 2011, vol. 33, pp. 1325-30.

H.Z. Liu, W.B. Hu, M.Y. Gu and R.J. Wu: J. Inorg. Mater., 2002, vol. 33, pp. 430-35.

H.D. Wang, H. Zhang, H.L. Li and Y.C. Tang: The Chinese Journal of Nonferrous Metals, 2007, vol. 17, pp. 991-95.

X.P. Zhang and S.L. Liu: J. Northeast Univ. Technol., 1993, vol. 14, pp. 28-31.

F.A. Nichols, J. Appl. Phys.: 1966, vol. 37, pp. 4599-02.

G.S. Li, L.P. Li, B.G. Juliana and B.F. Woodfield: J. Am. Chem. Soc., 2005, vol. 127, pp. 8659-66.

A.J. Song, M.Z. Ma, R.Z. Zhou, L. Wang, W.G. Zhang, C.L. Tan and R.P. Liu: Mater. Sci. Eng., 2012, vol. 538, pp. 219-23.

R. Chaim, Mater. Sci. Eng., 2007, vol. 443, pp. 25-32.

Acknowledgment

We thank the National Natural Science Foundation of China (No. 51774224) for financial support for this research.

Conflict of interest

There is no conflict of interest.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted June 3, 2019.

Rights and permissions

About this article

Cite this article

Li, X., Li, Y., Zhang, X. et al. Growth Characteristics of Metallic Iron Particles in the Direct Reduction of Nickel Slag. Metall Mater Trans B 51, 925–936 (2020). https://doi.org/10.1007/s11663-020-01799-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-020-01799-8